A kind of recovery method of valuable metal in silver-zinc slag

A technology of valuable metals and recycling methods, applied in the direction of improving process efficiency, etc., can solve the problems of step-by-step separation of silver and zinc slag, complex process flow, high production cost, etc., and achieve simple and clear process, reasonable process configuration, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

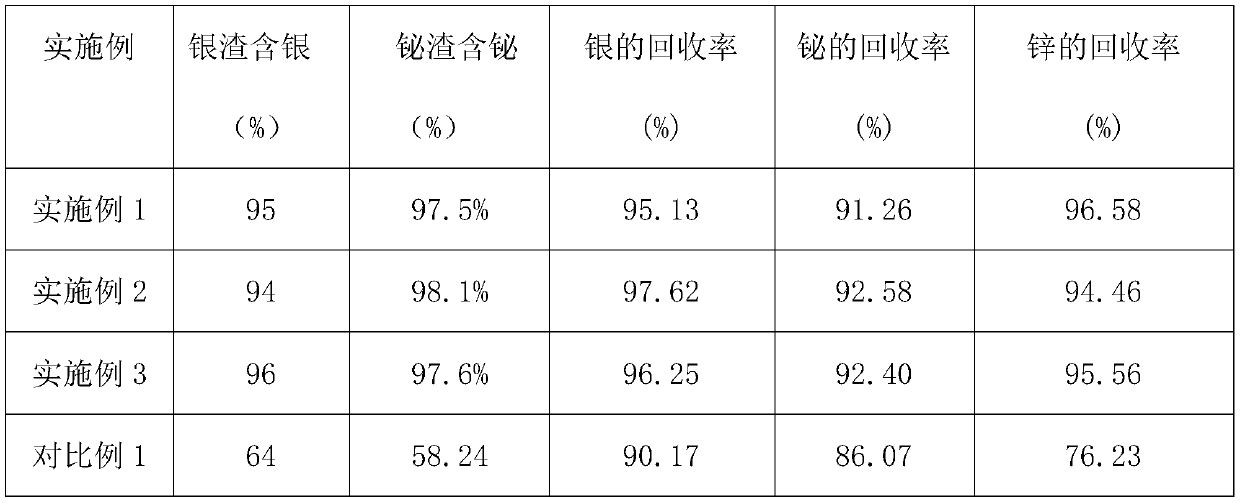

Embodiment 1

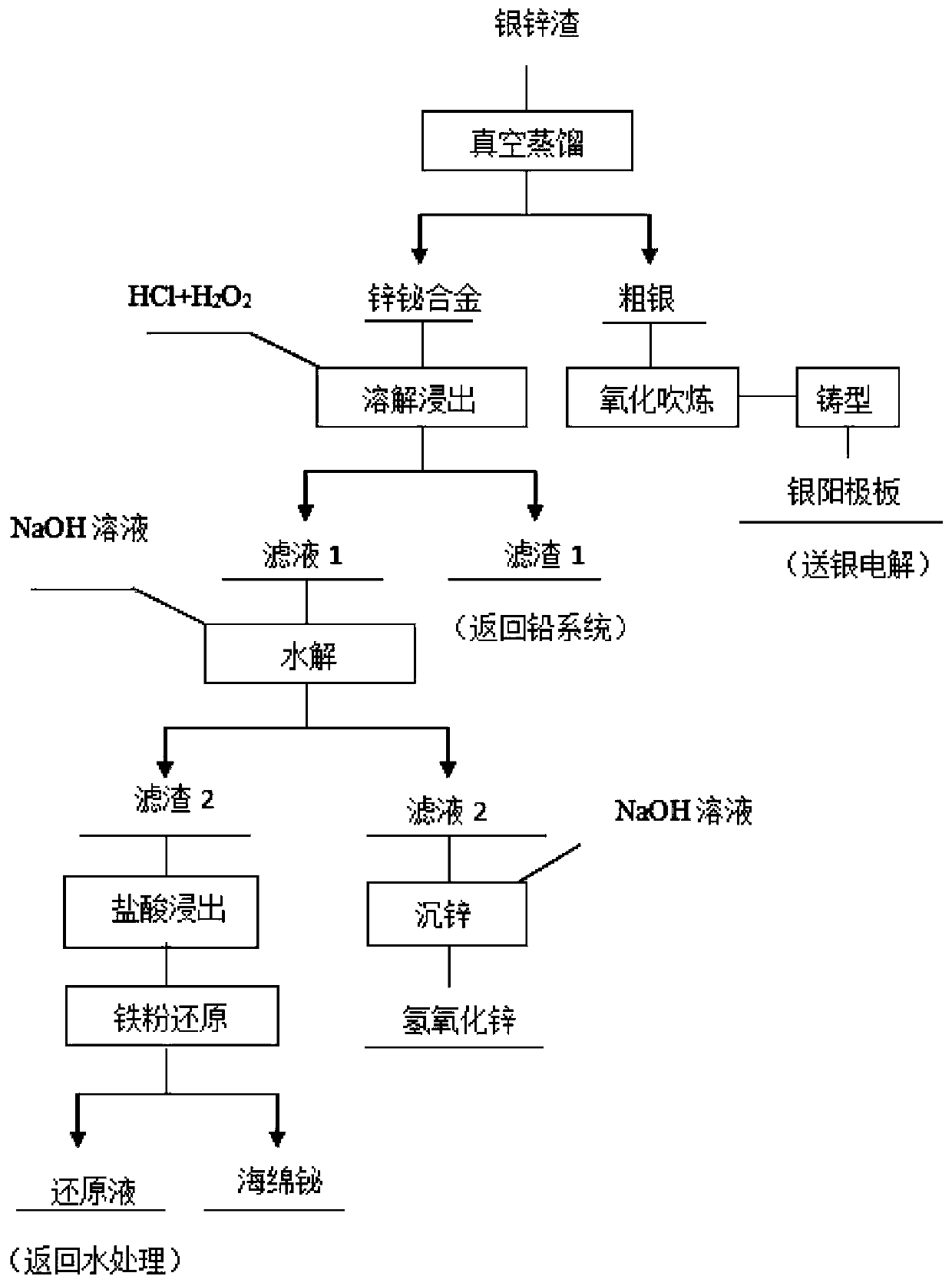

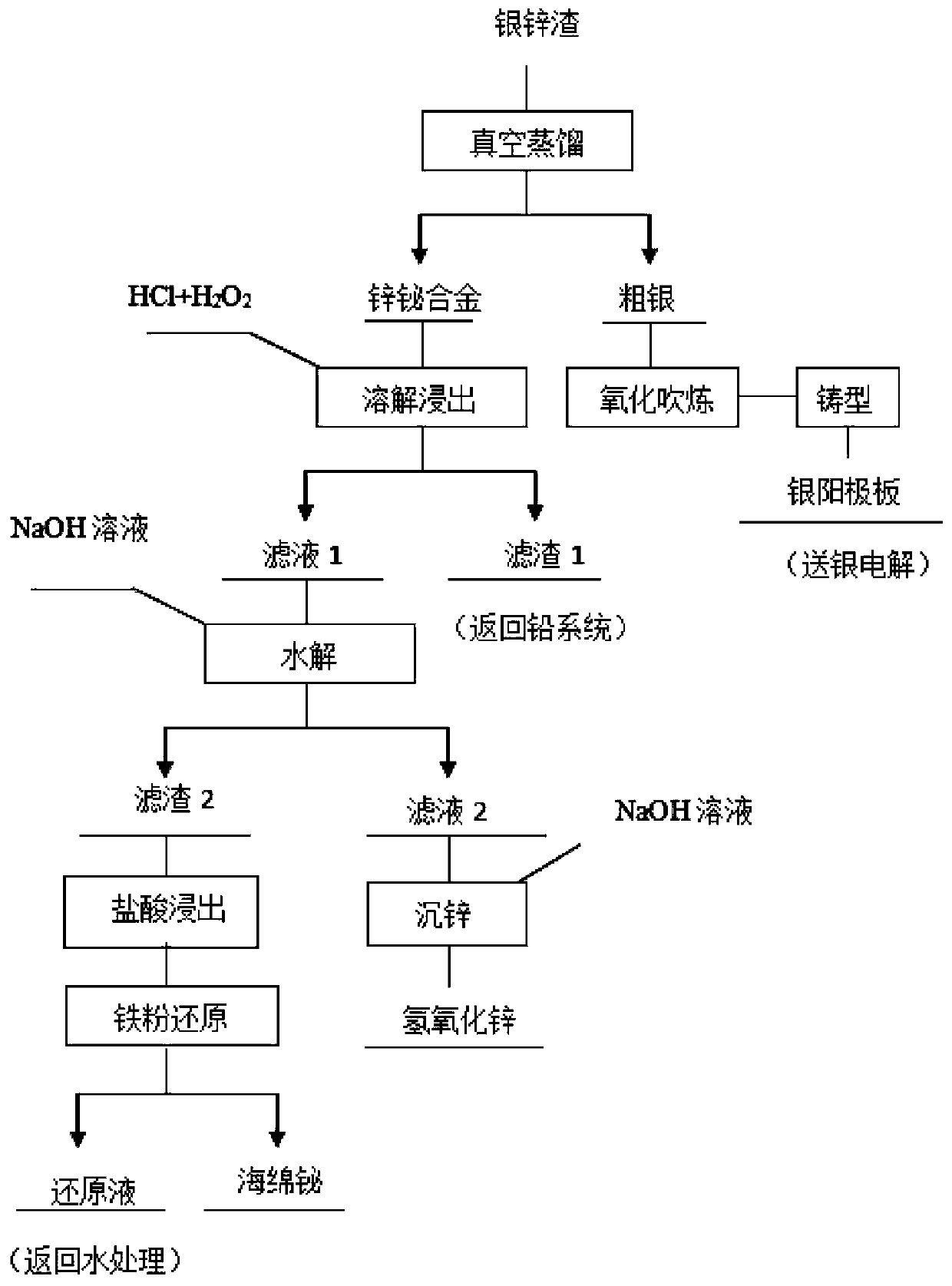

[0034] Process flow chart such as figure 1 As shown, the specific steps are as follows:

[0035] a) Vacuum distillation: take 1000Kg of silver-zinc slag, including Bi71.3%, Ag3.8%, Zn11.8%, Pb1.7%, and send it to a vacuum furnace for distillation. The vacuum degree is kept at 15Pa, at a temperature of 920°C Keep it warm for 2 hours to get rough silver and zinc-bismuth alloy. After the rough silver is oxidized and blown, the cast silver anode plate is sent to silver electrolysis.

[0036] b) Lead oxide sinking: HCl and H for zinc-bismuth alloy 2 o 2 The mixed solution is oxidized and leached, and the volume mass ratio of the mixed solution to the zinc-bismuth alloy is 4mL:1g; that is, 4mL of the mixed solution is added to 1g of silver-zinc slag, reacted at room temperature for 1.5h, and press filtration obtains filtrate 1 and filter residue 1, filter residue 1( Mainly lead chloride) returns to the lead system to extract lead.

[0037] c) Neutralization of sinking bismuth: a...

Embodiment 2

[0041] a) Vacuum distillation: take 1000Kg of silver-zinc slag, including Bi69.3%, Ag4.2%, Zn13.1%, Pb1.2%, and send it to a vacuum furnace for distillation. The vacuum degree is kept at 20Pa, at a temperature of 940°C Keep it warm for 2.5 hours to obtain crude silver and zinc-bismuth alloy. After the crude silver is oxidized and blown, the cast silver anode plate is sent to silver electrolysis.

[0042] b) Lead oxide sinking: HCl and H for zinc-bismuth alloy 2 o 2 The mixed solution is oxidized and leached, and the volume mass ratio of the mixed solution to the zinc-bismuth alloy is 5mL:1g; that is, 5mL of the mixed solution is added to 1g of silver-zinc slag, reacted at room temperature for 2h, and press-filtered to obtain filtrate 1 and filter residue 1, filter residue 1 (mainly for lead chloride) to return to the lead system to extract lead.

[0043] c) Neutralization of bismuth: add sodium hydroxide solution to filtrate 1 to adjust pH to 3.5, react at 70° C. for 1 hour ...

Embodiment 3

[0047] a) Vacuum distillation: take 1000Kg of silver-zinc slag, including Bi76.8%, Ag4.0%, Zn14.8%, Pb3.2%, and send it to a vacuum furnace for distillation. The vacuum degree is kept at 10Pa, at a temperature of 910°C Keep it warm for 1.5h to get rough silver and zinc-bismuth alloy, and cast silver anode plate to send silver electrolysis after oxidation blowing of crude silver.

[0048] b) Lead oxide sinking: HCl and H for zinc-bismuth alloy 2 o 2 The mixed solution is oxidized and leached, and the volume mass ratio of the mixed solution to the zinc-bismuth alloy is 6mL:1g; that is, 6mL of the mixed solution is added to 1g of silver-zinc slag, reacted at room temperature for 1h, and press-filtered to obtain filtrate 1 and filter residue 1, filter residue 1 (mainly for lead chloride) to return to the lead system to extract lead.

[0049] c) Neutralization of bismuth: add sodium hydroxide solution to filtrate 1 to adjust pH to 4, react at 60°C for 1.5 hours to hydrolyze bismu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com