Novel Portland cement and preparation method thereof

A Portland cement, a new type of technology, applied in the field of new Portland cement and its preparation, can solve the problems of large changes in the heat release rate of the cement system, reduced strength of cement specimens, and different shrinkage rates of cement, etc., to achieve reduction and Chloride ion diffusion inhibition performance, strength increase, seawater erosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

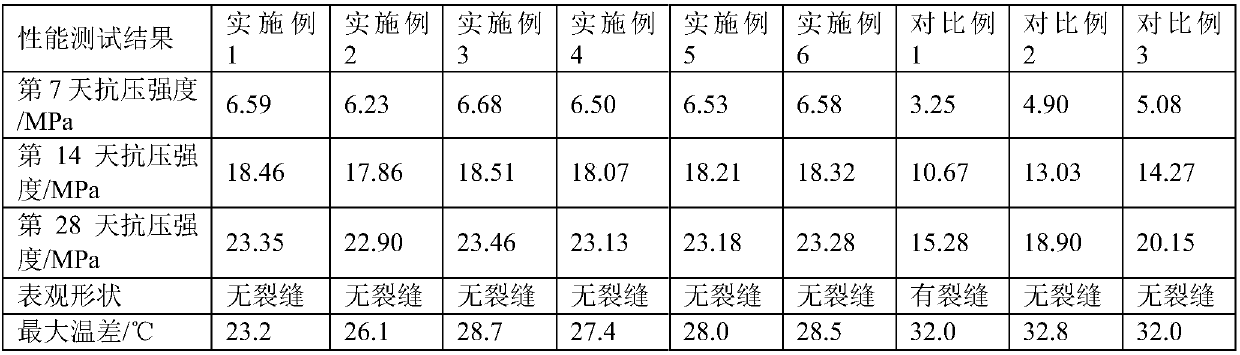

Examples

Embodiment 1

[0024] Preparation of external admixture: 1 kg of 1-(3-trifluoromethylphenyl) piperazine hydrochloride and 0.5 kg of 4-(4-fluorobenzoyl) piperidine hydrochloride are put into ethyl acetate, Raise the temperature of ethyl acetate to 31°C, stir evenly until it is completely dissolved, raise the temperature to 63°C for the second time to volatilize the solvent, and obtain the mixture after drying; then add 4kg of silica fume and calcium methacrylate to the mixture Salt hydrate 2kg, after uniform mixing, to obtain external admixture, wherein, the average particle diameter of silica fume is 0.2 μm, and specific surface area is 24m / g; The preparation of new portland cement: take clinker 65kg, superfine slag 17kg, 6kg of limestone, 6kg of gypsum, and 7.5kg of external admixture are uniformly mixed, and uniformly ground in a cement mill to obtain finished cement with an average particle size of 15μm.

Embodiment 2

[0026] Preparation of external ingredients: get 0.8kg of 1-(3-trifluoromethylphenyl)piperazine hydrochloride and 0.4kg of 4-(4-fluorobenzoyl)piperidine hydrochloride and put them into ethanol, Increase the temperature of ethanol to 28°C and stir evenly until it is completely dissolved, then raise the temperature to 66°C for the second time to volatilize the solvent and dry to obtain the mixture; then add 4.8kg of silica fume and hydrated calcium methacrylate to the mixture 1.6kg of material, after uniform mixing, to obtain external admixture, wherein, the average particle size of silica fume is 0.2μm, specific surface area is 28m / g; preparation of new Portland cement: take 60kg of clinker, 15kg of ultrafine slag, limestone 5kg, 5kg of gypsum, and 6kg of external admixture. After uniform mixing, they are evenly ground in a cement mill to obtain finished cement with an average particle size of 17μm.

Embodiment 3

[0028] Preparation of external admixture: 1.2kg of 1-(3-trifluoromethylphenyl)piperazine hydrochloride and 0.4kg of 4-(4-fluorobenzoyl)piperidine hydrochloride were put into methanol, and Raise the temperature of methanol to 28°C, stir evenly until it is completely dissolved, raise the temperature to 66°C for the second time to volatilize the solvent, and dry the mixture to obtain the mixture; then add 3.2kg of silica fume and calcium methacrylate to the mixture for hydration 2.4kg of material, after uniform mixing, to obtain external admixture, wherein, the average particle size of silica fume is 0.3μm, specific surface area is 28m / g; new Portland cement preparation: take clinker 60kg, superfine slag 19kg, limestone 5kg, 5kg of gypsum, and 6kg of external admixture. After uniform mixing, they are evenly ground in a cement mill to obtain finished cement with an average particle size of 17μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com