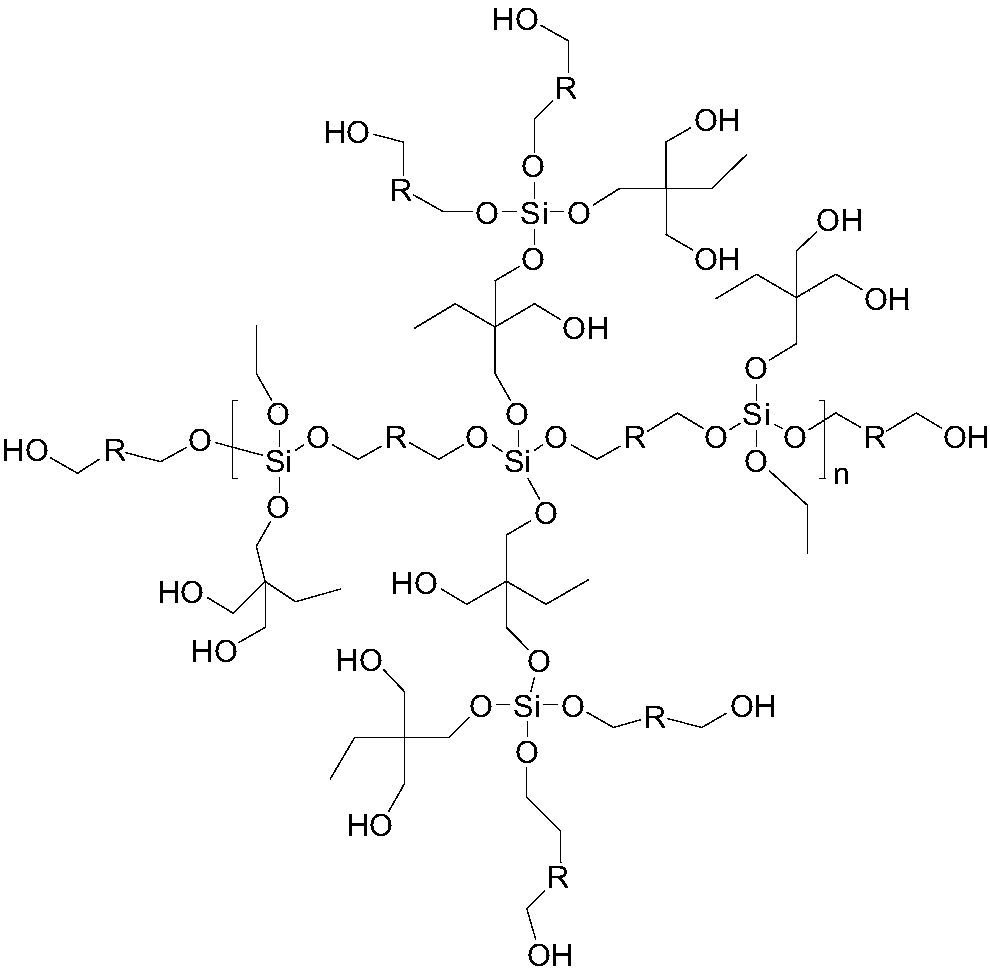

Surface superhydrophobic TPU (thermoplastic polyurethane) film and preparation method thereof

A super-hydrophobic and thin-film technology, which is applied in the field of bio-based degradable materials, can solve the problems of unfavorable industrial production, complex methods, and inapplicability of bio-based materials, etc., and achieve good application prospects, simple preparation methods, and good super-hydrophobic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The TPU film prepared in this embodiment includes the following components by weight:

[0045]

[0046](1) Add hydroxyl-terminated hyperbranched silicon oxide, diisocyanate (wherein the mass ratio of toluene diisocyanate to hexamethylene diisocyanate is 6:1), polyethylene glycol 2000, ethylene glycol, stannous octoate and antioxidant 1010 In the container, under the stirring speed of 150r / min, vacuum dehydration at 80°C under the pressure of -0.2kPa, and then react at 130°C for 5h;

[0047] (2) Then use the twin-screw extruder to extrude the product obtained in step (1), wherein the temperature of the feeding section of the twin-screw extruder is 115°C, the temperature of the mixing section is 145°C, and the temperature of the extrusion section is 175°C , the head temperature is 155°C, and a super-hydrophobic TPU film is obtained after extrusion.

Embodiment 2

[0049] The TPU film prepared in this embodiment includes the following components by weight:

[0050]

[0051]

[0052] (1) Hydroxyl-terminated hyperbranched silicon dioxide, diisocyanate (the mass ratio of toluene diisocyanate to hexamethylene diisocyanate is 5:1), polyethylene glycol 400, 1,3-propylene glycol, dibutyltin dioctoate and anti- Oxygen agent 264 was added to the container, under the stirring speed of 200r / min, vacuum dehydration at 90°C under the pressure of -0.3kPa, and then reacted at 140°C for 3h;

[0053] (2) Then use a twin-screw extruder to extrude the product obtained in step (1), wherein the temperature of the feeding section of the twin-screw extruder is 110°C, the temperature of the mixing section is 140°C, and the temperature of the extrusion section is 170°C , the head temperature is 150°C, and a super-hydrophobic TPU film is obtained after extrusion.

Embodiment 3

[0055] The TPU film prepared in this embodiment includes the following components by weight:

[0056]

[0057] (1) Hydroxyl-terminated hyperbranched silicon oxide, diisocyanate (the mass ratio of toluene diisocyanate to hexamethylene diisocyanate is 8:1), polyethylene glycol 5000, 1,4-butanediol, dibutyl laurate Add tin and antioxidant TPP into the container, under the stirring speed of 100r / min, vacuum dehydrate at 70°C under the pressure of -0.1kPa, and then react at 120°C for 8h;

[0058] (2) Then use a twin-screw extruder to extrude the product obtained in step (1), wherein the temperature of the feeding section of the twin-screw extruder is 120°C, the temperature of the mixing section is 150°C, and the temperature of the extrusion section is 180°C , the head temperature is 160°C, and a TPU film with a superhydrophobic surface is obtained after extrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com