Non-metal-doped porous wall titanium nano-tube array visible light catalyst, preparation method and applications thereof

A titanium nanotube and non-metallic technology, which is applied in the preparation of non-metallic doped porous-walled titanium nanotube array visible light catalyst and the application field of environmental treatment, which can solve the problem of low sunlight utilization rate of pure titanium nanotube array and noble metal electrodes. High cost, unstable doping amount and other issues, to achieve the effect of improved visible light catalytic activity, high light utilization rate, adsorption and mass transfer efficiency, and rich pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Titanium alloy pretreatment: Take a 20mm×30mm×2mm pure titanium sheet coated with a TiN coating with a thickness of 10 μm, put it into absolute ethanol and deionized water for 20 minutes each, and dry at room temperature.

[0032] (2) Anodizing: Two-electrode system is used, the cathode is pure titanium sheet (effective area 400mm 2 ), the anode is the pure titanium sheet coated with TiN coating after the step (1) treatment, and the area to be anodized is 2 × 400mm 2 , the distance between the two electrodes is 3cm, and the electrolyte is 0.5wt% NH 4 F, 2vol%H 2O in ethylene glycol solution 60mL. Oxidation was carried out at 70V DC constant voltage for 3h, and the initial temperature of the electrolyte was 20°C. Soak in absolute ethanol for 20-40 minutes, then dry naturally at room temperature to obtain amorphous N-doped TiO 2 array of nanotubes.

Embodiment 2

[0034] (1) Titanium alloy pretreatment: Take a 20mm×30mm×2mm pure titanium sheet coated with a TiC coating with a thickness of 10 μm, put it into anhydrous ethanol and deionized water for 20 minutes each, and dry at room temperature.

[0035] (2) Anodizing: Two-electrode system is used, the cathode is pure titanium sheet (effective area 400mm 2 ), the anode is the pure titanium sheet coated with TiC coating after the step (1) treatment, and the area to be anodized is 2 × 400mm 2 , the distance between the two electrodes is 3cm, and the electrolyte is 0.5wt% NH 4 F, 2vol%H 2 O in ethylene glycol solution 60mL. Oxidize for 3 hours under 70V DC constant voltage, the initial temperature of the electrolyte is 20°C, no need to maintain constant temperature. Soak in absolute ethanol for 20-40min, then dry naturally at room temperature to obtain amorphous C-doped TiO 2 array of nanotubes.

Embodiment 3

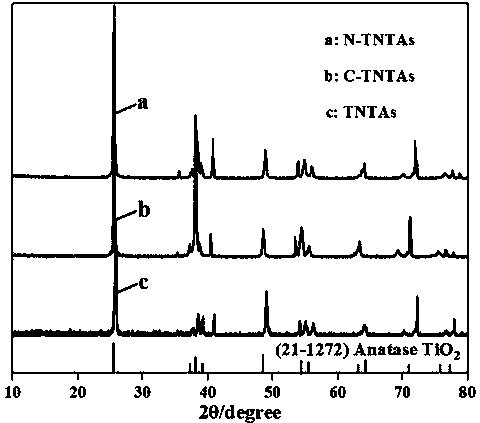

[0037] (1) Preparation of anatase N-doped porous-walled titanium nanotube arrays: the amorphous N-doped TiO prepared in Example 1 2 The nanotube arrays were calcined in a muffle furnace at 500°C for 2 hours in an air atmosphere. The temperature rise program is to rise from room temperature to 250°C at a rate of 2°C / min, keep the temperature at 250°C for 30 minutes, then rise to 500°C at a rate of 1°C / min, keep the temperature for 2 hours, and finally drop to room temperature at a rate of 3°C / min , to obtain anatase N-doped porous-walled titanium nanotube arrays, denoted as N-TNTAs.

[0038] (2) Preparation of anatase C-doped porous-walled titanium nanotube arrays: the amorphous C-doped TiO prepared in Example 2 2 The nanotube arrays were calcined in a muffle furnace at 500°C for 2 hours in an air atmosphere. The temperature rise program is to rise from room temperature to 250°C at a rate of 2°C / min, keep the temperature at 250°C for 30 minutes, then rise to 500°C at a rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com