Ferrocobalt selenide and preparation method and application thereof

A technology of selenide and cobalt iron, which is applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of unsatisfactory electrocatalytic properties such as stability and price disadvantages, and achieve simple preparation methods, The effect of small turn-on voltage and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

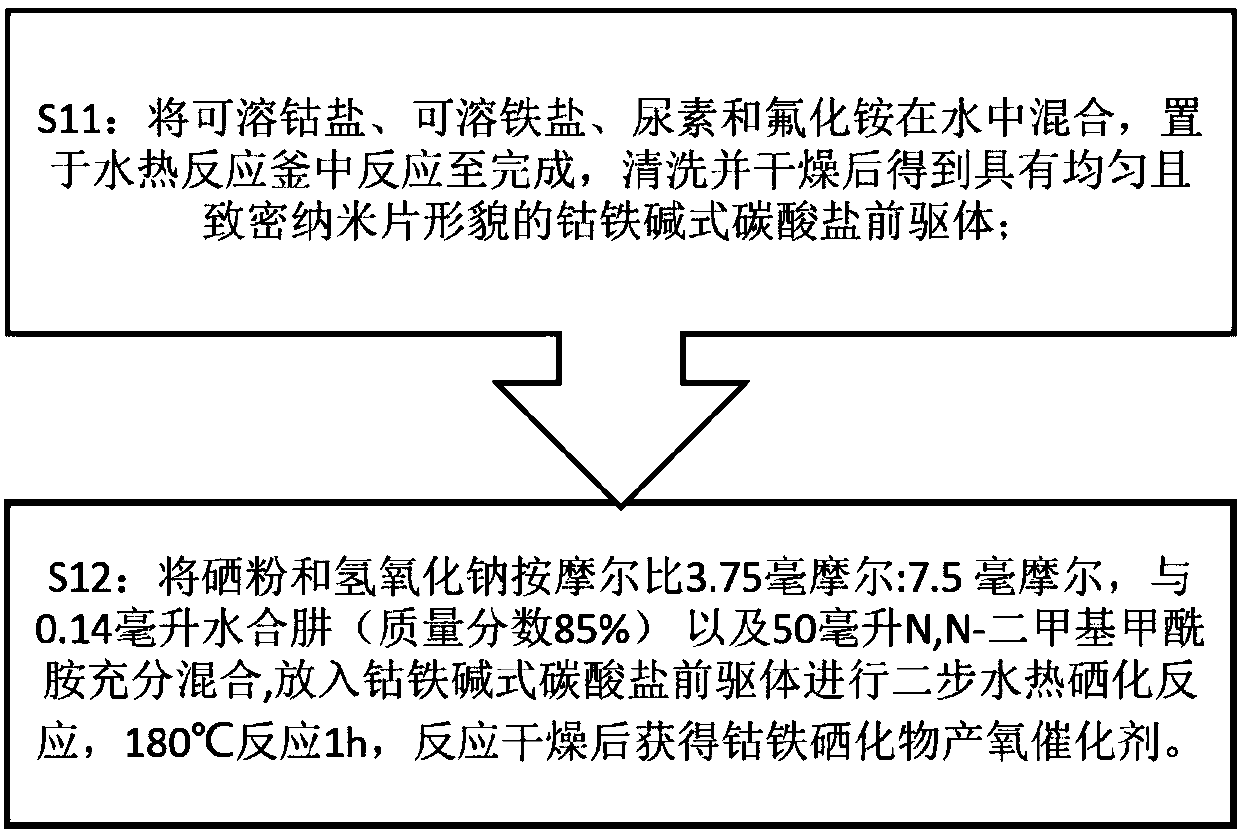

[0032] The invention provides a kind of preparation method of cobalt iron selenide, comprises the steps:

[0033] (1) Put the mixed aqueous solution of soluble cobalt salt, soluble iron salt, soluble ammonium salt and carbon-containing precipitant together with the conductive substrate in a hydrothermal reaction vessel for hydrothermal reaction to obtain nano-sheet-shaped cobalt-ferrite base Formula carbonate precursor; wherein the molar ratio of soluble cobalt salt, soluble iron salt, soluble ammonium salt and carbon-containing precipitant in the mixed aqueous solution is 1:1.5: (1~20): (10~50) , the concentration of the soluble ammonium salt is 0.01-0.3mol / L;

[0034] The conductive substrate is a conductive metal substrate, such as nickel foam, copper foam, etc., preferably nickel foam; the nickel foam can be of various sizes. The carbon-containing precipitant is preferably urea. At the hydrothermal reaction temperature, urea reacts with other raw materials to bind metal a...

Embodiment 1

[0040]figure 1 Show the preparation process of the cobalt iron selenide oxygen production catalyst that this example provides, comprise the steps:

[0041] (1) Precursor preparation: 1 mmol of cobalt nitrate, 1.5 mmol of ferric nitrate, 10 mmol of ammonium fluoride, and 25 mmol of urea raw materials were dissolved in 40 mL of deionized water, and hydrothermally reacted at 120°C for 16 hours. Wash and dry to obtain the precursor.

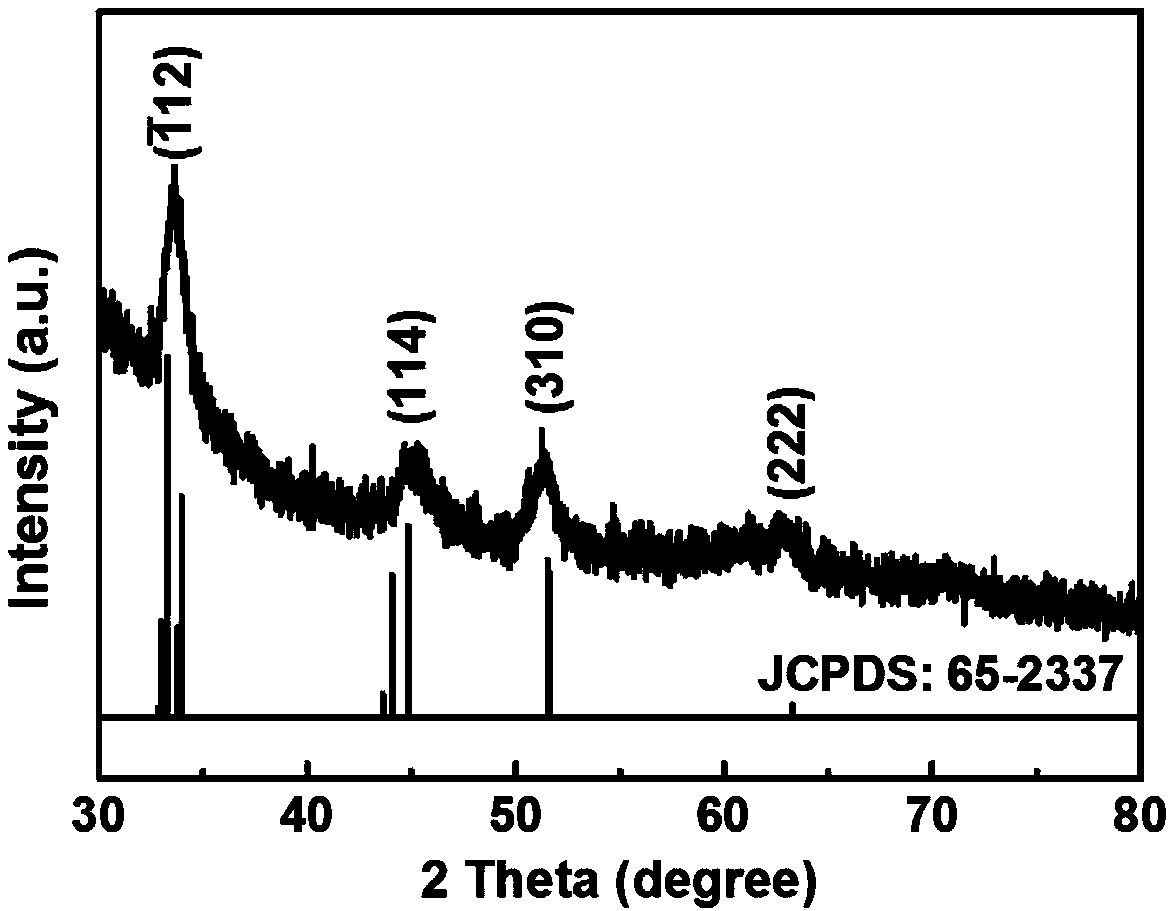

[0042] (2) Stabilized cobalt-iron-selenium nanosheets: Selenium powder and sodium hydroxide are mixed in a molar ratio of 3.75 mmol: 7.5 mmol, with 0.14 milliliters of hydrazine hydrate (mass fraction 85%) and 50 milliliters of N,N-dimethylformazan The amides are fully mixed, put into the cobalt-iron basic carbonate precursor to carry out two-step hydrothermal selenization reaction, react at 180°C for 1 hour, and obtain the cobalt-iron selenide oxygen generation catalyst after the reaction is dried. figure 2 The scanning electron microscope image o...

Embodiment 2

[0050] (1) Precursor preparation: 1 mmol of cobalt nitrate, 1.5 mmol of ferric nitrate, 10 mmol of ammonium fluoride, and 25 mmol of urea raw materials were dissolved in 40 mL of deionized water, and hydrothermally reacted at 120°C for 16 hours. Wash and dry to obtain the precursor.

[0051] (2) Stable cobalt-iron-selenium nanosheets: Selenium powder and sodium hydroxide are mixed in a molar ratio of 3.75 mmol: 7.5 mmol, with 1 ml of hydrazine hydrate (mass fraction 85%) and 50 ml of N,N-dimethylformazan The amides are fully mixed, and the cobalt-iron basic carbonate precursor is put into a two-step hydrothermal selenization reaction, reacted at 200°C for 6 hours, and the cobalt-iron selenide oxygen generation catalyst is obtained after the reaction is dried.

[0052] (3) Electrode preparation: the cobalt-iron-selenide oxygen-generating catalyst was finally dried at 60° C. for 12 hours, and a small piece of 1 square centimeter was cut out to obtain an electrode. The electroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com