A kind of method for preparing the multistage porous ZSM-5 molecular sieve that is used for methanol to propylene

A ZSM-5, methanol-to-propylene technology, applied in molecular sieve catalysts, chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, etc. Effects of methanol conversion activity, shortened diffusion path, and good carbon deposition resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

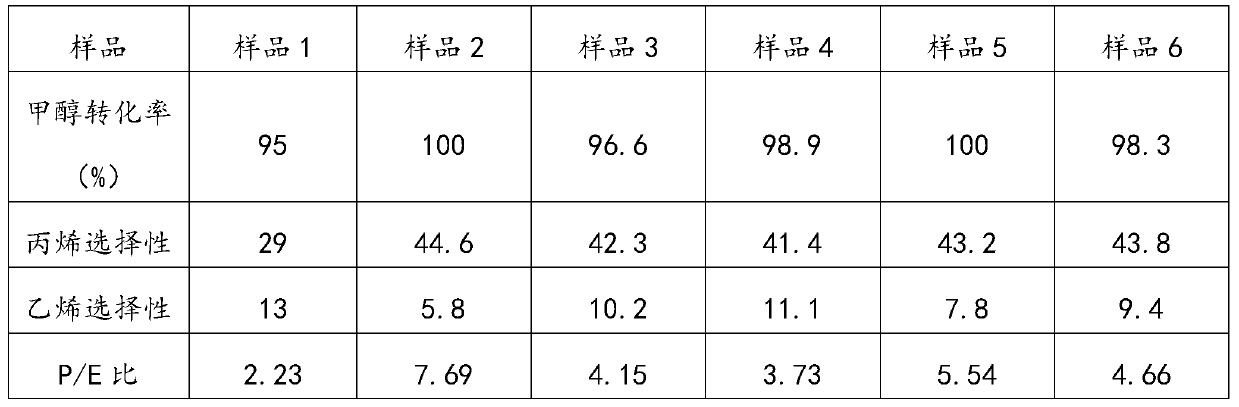

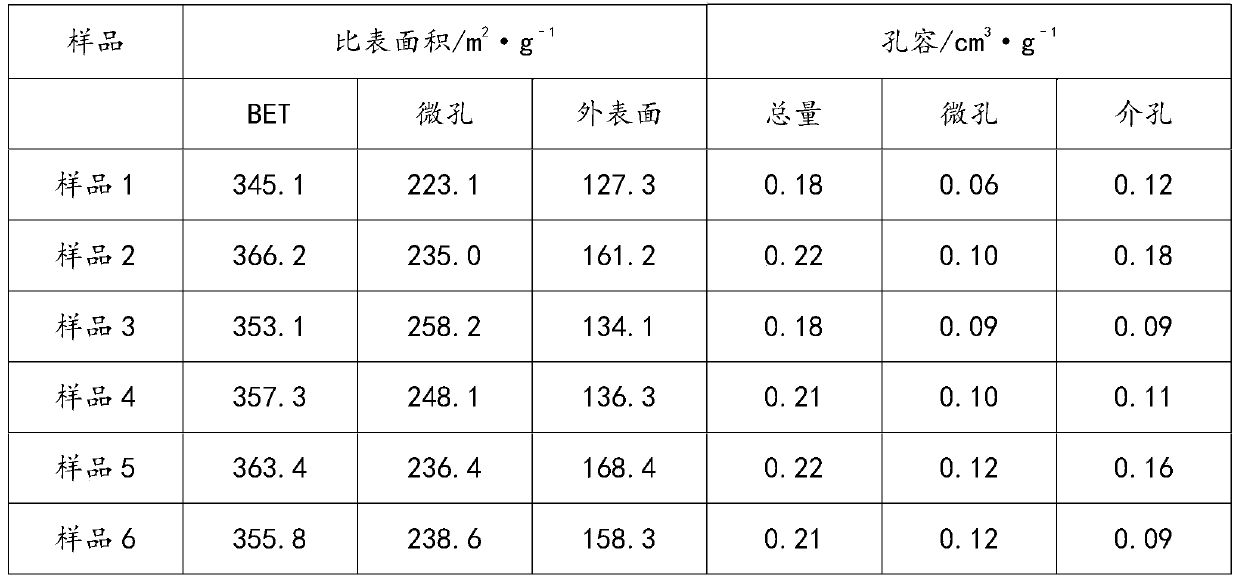

[0031] Embodiment 1: with 40% silica sol as silicon source, sodium metaaluminate (NaAlO2) is aluminum source, sodium hydroxide (NaOH) is alkali source, according to 1Al2O3: 200SiO2: 25NaOH: 1500H2O ratio prepares gel, crystal The amount of addition is 5% (mass fraction). Place in a crystallization kettle, first crystallize at 120°C for 6h, cool rapidly, add 5wt% octadecyltrimethylammonium bromide (STPA) of the pre-crystallized product, reflux at 90°C for 6h, then move into In a hydrothermal synthesis reaction kettle, crystallize at 180°C for 24 hours, centrifuge and wash with deionized water several times, and dry at 120°C for 12 hours to obtain ZSM-5 molecular sieve powder I. Exchange with 0.1mol / L hydrochloric acid at a liquid-solid mass ratio of 20:1 and a temperature of 90°C to obtain H-type molecular sieve precursor II after washing, drying, and roasting; use 3mol / L ammonium sulfate at 90 Under the condition of ℃, it was exchanged twice for 2 hours each time, and then wa...

Embodiment 2

[0032] Example 2: Using the molecular sieve raw powder I prepared in Example 1, exchange it with 3mol / L hydrochloric acid at a liquid-solid mass ratio of 5:1, and at a temperature of 90°C, and obtain after washing, drying, and roasting H-type molecular sieve precursor II; use 1mol / L ammonium chloride at a liquid-solid ratio of 10:1, exchange twice at 90°C for 3h each time, wash, dry, and roast at 350°C for 12h to obtain Desired catalyst (sample 3). Under the same evaluation conditions as in Comparative Example 1, the distribution of main products is shown in Table 1, and the BET characterization results of the catalyst are shown in Table 2.

Embodiment 3

[0033] Example 3: Using the molecular sieve powder I prepared in Example 1, exchange it with 3 mol / L hydrochloric acid at a liquid-solid mass ratio of 15:1, and at a temperature of 90°C, and obtain after washing, drying, and roasting H-type molecular sieve precursor II; use 2mol / L ammonium sulfate at a liquid-to-solid ratio of 10:1, exchange twice at 90°C for 4h each time, wash, dry, and roast at 450°C for 12h to obtain Desired catalyst (sample 4). Under the same evaluation conditions as in Comparative Example 1, the distribution of main products is shown in Table 1, and the BET characterization results of the catalyst are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com