Remediation modifier for heavy-metal cadmium polluted soil and preparation method of remediation modifier

A technology for cadmium-contaminated soil and heavy metals, applied in soil conditioning materials, chemical instruments and methods, urea compound fertilizers, etc., can solve problems such as single function, complicated application methods, and limited use conditions, and achieve reduced bulk density and improved application methods. Simple, hard-to-absorb effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

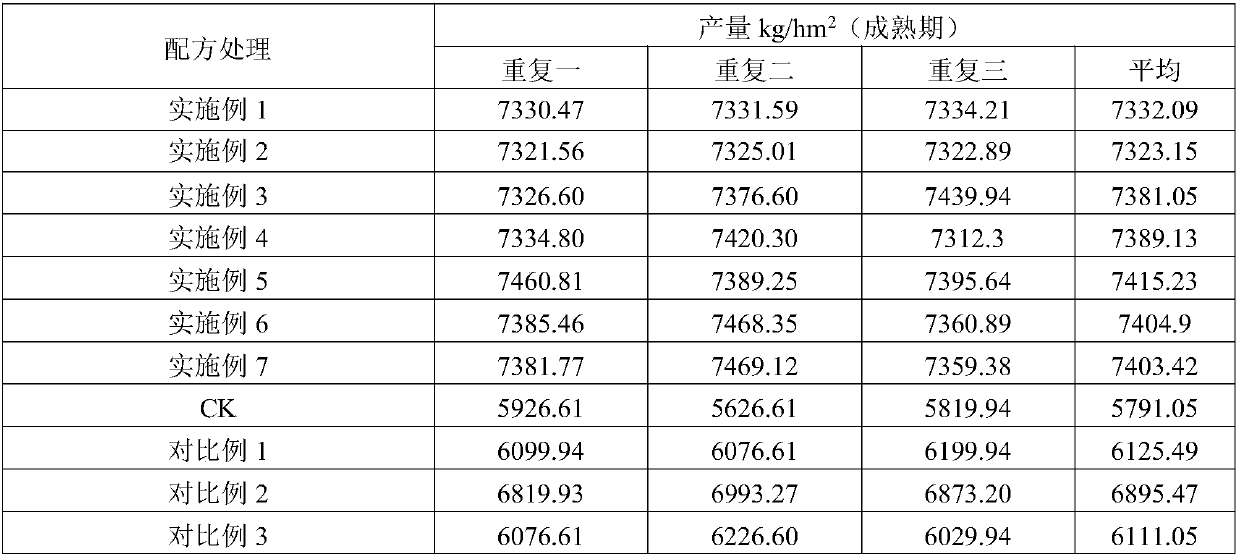

Examples

Embodiment 1

[0030] A heavy metal cadmium polluted soil repair and improvement agent, comprising the following components by weight: 1 part of urea, 8 parts of superphosphate, 1 part of potassium chloride, 6 parts of lime, 0.4 parts of wood vinegar, 70 parts of biochar, powder 18 parts of coal ash. The preparation method is as follows: (1) take wheat straw as raw material and pyrolyze it in a carbonization furnace at 700 DEG C for 4 hours to obtain biochar, and then grind and sieve the biochar to obtain 40-60 mesh samples. At the same time, during the pyrolysis process, the straw will produce pyrolyzed volatiles, which are sent to the cooler for cooling and collection to obtain condensed liquid, that is, wood vinegar, and the cooling temperature is normal temperature. (2) The purchased urea, superphosphate, potassium chloride and lime are ground and passed through a 40-60 mesh sieve to obtain a sample. The fly ash comes from a power plant, and the fly ash is directly passed through a 40-6...

Embodiment 2

[0032] A heavy metal cadmium polluted soil repair and improvement agent, comprising the following components by weight: 2 parts of urea, 6 parts of superphosphate, 2 parts of potassium chloride, 4 parts of lime, 0.6 parts of wood vinegar, 74 parts of biochar, powder 14 parts of coal ash. The preparation method is as follows: (1) taking corn stalks as raw materials and pyrolyzing them in a carbonization furnace at 400° C. for 6 hours to obtain biochar, and then grinding and sieving the biochar to obtain 40-60 mesh samples. At the same time, during the pyrolysis process, the straw will produce pyrolyzed volatiles, which are sent to the cooler for cooling and collection to obtain condensed liquid, that is, wood vinegar, and the cooling temperature is normal temperature. (2) The purchased urea, superphosphate, potassium chloride and lime are ground and passed through a 40-60 mesh sieve to obtain a sample. The fly ash comes from a power plant, and the fly ash is directly passed th...

Embodiment 3

[0034] A heavy metal cadmium polluted soil repairing and improving agent, comprising the following components by weight: 1.8 parts of urea, 7 parts of superphosphate, 1.3 parts of potassium chloride, 5 parts of lime, 0.5 parts of wood vinegar, 72 parts of biochar, powder 16 parts of coal ash. The preparation method is as follows: (1) using rice stalks as raw materials to pyrolyze in a carbonization furnace at 600 DEG C for 5 hours in the absence of oxygen to prepare biochar, and then grind and sieve the biochar to obtain 40-60 mesh samples. At the same time, during the pyrolysis process, the straw will produce pyrolyzed volatiles, which are sent to the cooler for cooling and collection to obtain condensed liquid, that is, wood vinegar, and the cooling temperature is normal temperature. (2) The purchased urea, superphosphate, potassium chloride and lime are ground and passed through a 40-60 mesh sieve to obtain a sample. The fly ash comes from a power plant, and the fly ash is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com