Sulforaphen extraction process

A technology of sulforaphane and extraction process, applied in the directions of organic chemistry, fermentation, etc., can solve the problems of many chemical reagents, high price, high extraction rate and high extraction rate, avoiding the residue of toxic and harmful substances, saving the extraction cost, and reducing the degradation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: A process for extracting sulforaphane, comprising the following steps: take dried broccoli seeds and grind them into powder to obtain dry powder, mix 10 g of dry powder with 20 ml of water, enzymolyze it in a water bath at 40°C for 1 hour, and after enzymolysis Add 100ml of methanol and ultrasonically extract at 25°C for 60 minutes to obtain an extract, take the extract, centrifuge it, and freeze-dry the supernatant to obtain sulforaphane.

[0042] The product sulforaphane at this place is crude product, and the product quality that obtains is 1.5g, and wherein getting dry broccoli seed quality is 10g; Get the crude product of product sulforaphane and adopt high performance liquid chromatography to detect the sulforaphane content in the extract. 20.8%.

[0043] The crude sulforaphane product was taken, and 1.3 g of purified sulforaphane was obtained through conventional purification methods, such as silica gel column chromatography, and the content of sulfora...

Embodiment 2

[0044] Example 2: A process for extracting sulforaphane, comprising the following steps: take dried broccoli seeds, peel them and grind them into powder to obtain dry powder, mix 10 g of dry powder with 35 ml of water, enzymolyze in a water bath at 35°C for 8 hours, and after enzymolysis Add 80ml of methanol and extract by ultrasonic wave at 35°C for 30min to obtain the extract, take the extract and centrifuge, take the supernatant and freeze-dry to obtain sulforaphane.

[0045] The product sulforaphane at this place is crude product, and the product quality that obtains is 1.2g, and wherein getting dry broccoli seed quality is 10g; Get the crude product of product sulforaphane and adopt high performance liquid chromatography to detect the sulforaphane content in the extract. 39.4%.

[0046]The crude sulforaphane product was taken, and 1 g of purified sulforaphane was obtained through conventional purification methods, such as silica gel column chromatography, and the content ...

Embodiment 3

[0047] Example 3: A process for extracting sulforaphane, comprising the following steps: take dried broccoli seeds and grind them into powder to obtain dry powder, mix 10 g of dry powder with 30 ml of water, enzymolyze in a water bath at 30° C. for 10 h, and after enzymolysis Add 70ml of methanol and extract by ultrasonic wave at 50°C for 20min to obtain the extract, take the extract and centrifuge, take the supernatant and freeze-dry to obtain sulforaphane.

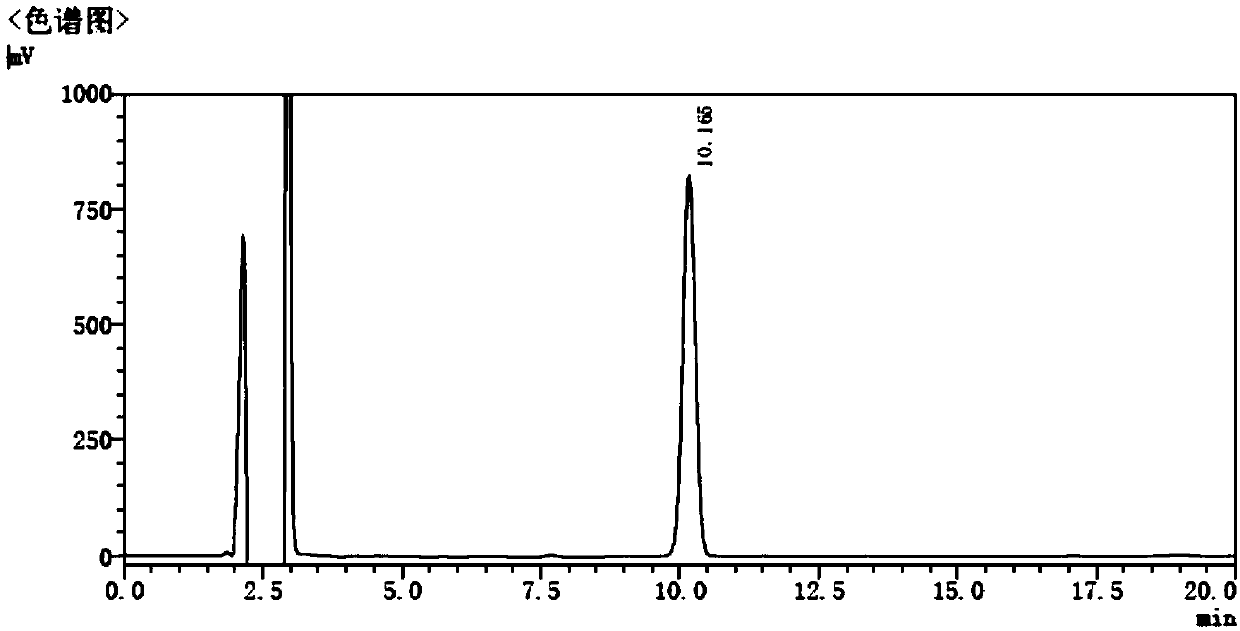

[0048] The product sulforaphane in this place is a crude product, and the quality of the product obtained is 2g, wherein the dry broccoli seed quality is 10g; figure 1 As shown, take the crude product of sulforaphane and use high performance liquid chromatography to detect that the content of sulforaphane in the extract is 23.6%.

[0049] The crude sulforaphane product was taken, and 1.5 g of purified sulforaphane was obtained through conventional purification methods, such as silica gel column chromatography, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com