A kind of metal paint surface crystal plating material and preparation method thereof

A metal paint and crystal plating technology, which is applied in anti-corrosion coatings, fire-proof coatings, paints containing biocides, etc., can solve the problems of easy scratches on the surface of metal paint, poor yellowing resistance, and difficult cleaning, etc., to achieve super strength Self-cleaning, gloss-enhancing, and dust-resistant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

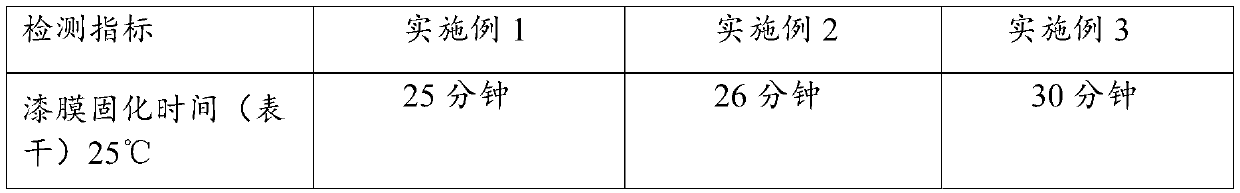

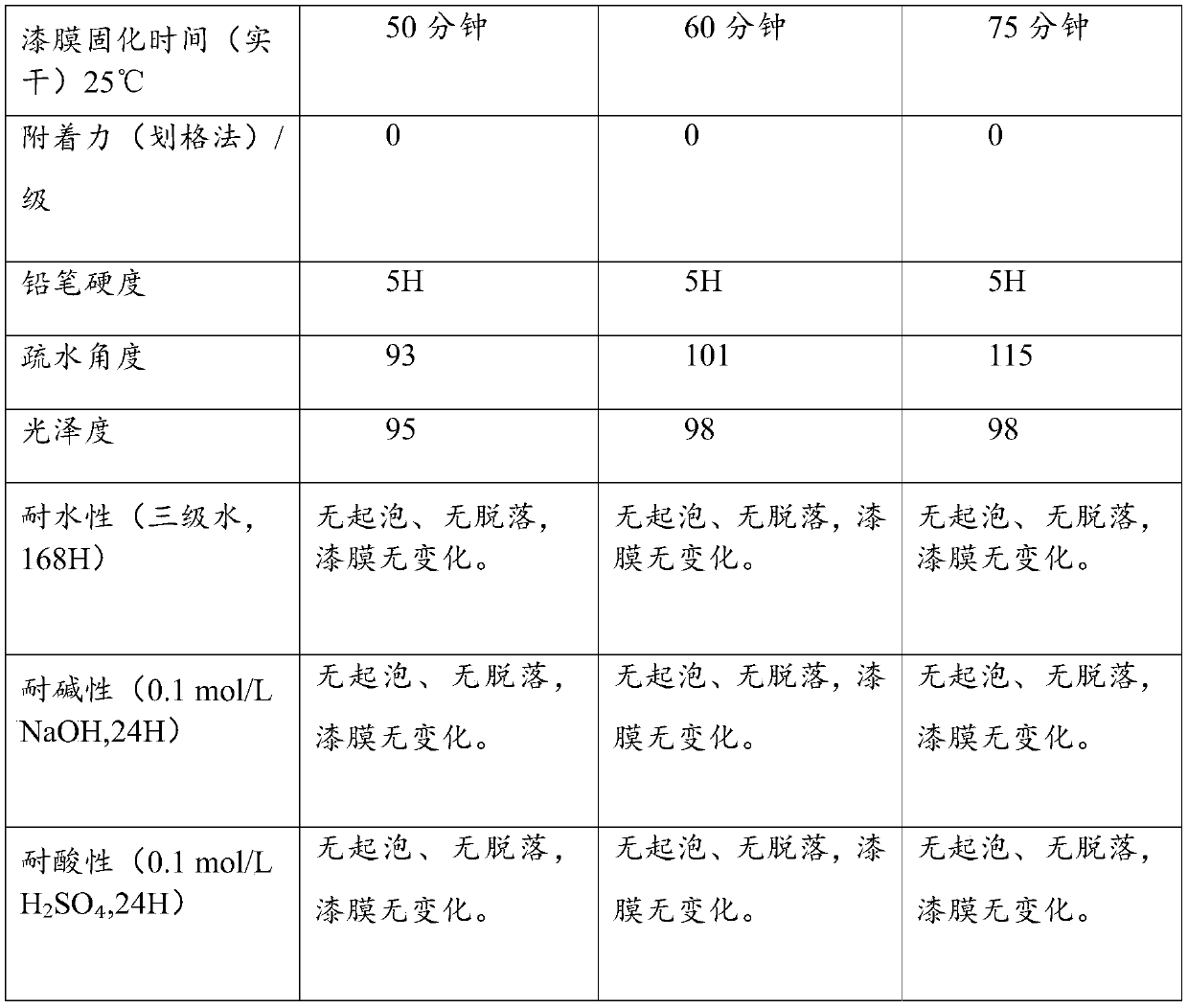

Embodiment 1

[0036] An embodiment of the metal paint surface crystallization material of the present invention, the metal paint surface crystallization material of this embodiment contains the following components by weight:

[0037] 35 parts of methyl silicone resin, 0.1 part of 3-aminopropyltriethoxysilane, 63 parts of organic solvent (butyl acetate), 0.2 part of leveling agent (Tego Glide 410), fluorine-containing surfactant (DuPont Fluorine Carbon surfactant Capstone FS-3100) 0.3 part, UV absorber (BASF 1130) 0.2 part, defoamer (BYK065) 0.1 part, polydimethylsiloxane (hydroxyl value 28mg KOH / g) 0.2 part, catalyst (DBTDL) 0.001 part, isocyanate (MDI) 0.1 part.

[0038] The preparation method of the crystal plating material on the surface of the metallic paint described in this embodiment includes the following steps:

[0039] (1) Mix isocyanate, polydimethylsiloxane, and catalyst uniformly in a reaction vessel, and then react at 60°C for 4 hours;

[0040] (2) Add the silicone resin and organic...

Embodiment 2

[0045] An embodiment of the metal paint surface crystallization material of the present invention, the metal paint surface crystallization material of this embodiment contains the following components by weight:

[0046] 40 parts of methyl silicone resin, 0.15 parts of 3-aminopropyltrimethoxysilane, 59 parts of organic solvent (toluene), 0.25 parts of leveling agent (Tego Glide 420), fluorine-containing surfactant (DuPont fluorocarbon surface active Capstone FS-3100) 0.4 parts, ultraviolet absorber (BASF 1130) 0.25 parts, defoamer (BYK065) 0.15 parts, polydimethylsiloxane (hydroxyl value 58mg KOH / g) 0.25 parts, catalyst (TEA) 0.003 parts and 0.15 parts of isocyanate (TDI).

[0047] The preparation method of the crystal plating material on the surface of the metallic paint described in this embodiment includes the following steps:

[0048] (1) Mix isocyanate, polydimethylsiloxane, and catalyst uniformly in a reaction vessel, and then react at 60°C for 4 hours;

[0049] (2) Add the sil...

Embodiment 3

[0054] An embodiment of the metal paint surface crystallization material of the present invention, the metal paint surface crystallization material of this embodiment contains the following components by weight:

[0055] 45 parts of methyl silicone resin, 0.2 parts of 3-aminopropyltriethoxysilane, 53 parts of organic solvent (tetrahydrofuran), 0.3 parts of leveling agent (Tego Glide 432), fluorosurfactant (DuPont fluorocarbon surface) Active agent Capstone FS-3100) 0.5 part, UV absorber (BASF 1130) 0.3 part, defoamer (Deqian 5300) 0.2 part, polysiloxane (hydroxyl value 105mg KOH / g) 0.3 part, catalyst (DBTDL) 0.005 parts and 0.2 parts of isocyanate (TMDI).

[0056] The preparation method of the crystal plating material on the surface of the metallic paint described in this embodiment includes the following steps:

[0057] (1) Mix isocyanate, polydimethylsiloxane, and catalyst uniformly in a reaction vessel, and then react at 60°C for 4 hours;

[0058] (2) Add the silicone resin and or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com