Treatment method of surface of oxygen-free copper

A treatment method, oxygen-free copper technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of employee safety hazards, difficult to remove, affecting product use and life, etc., to achieve a good combination force, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

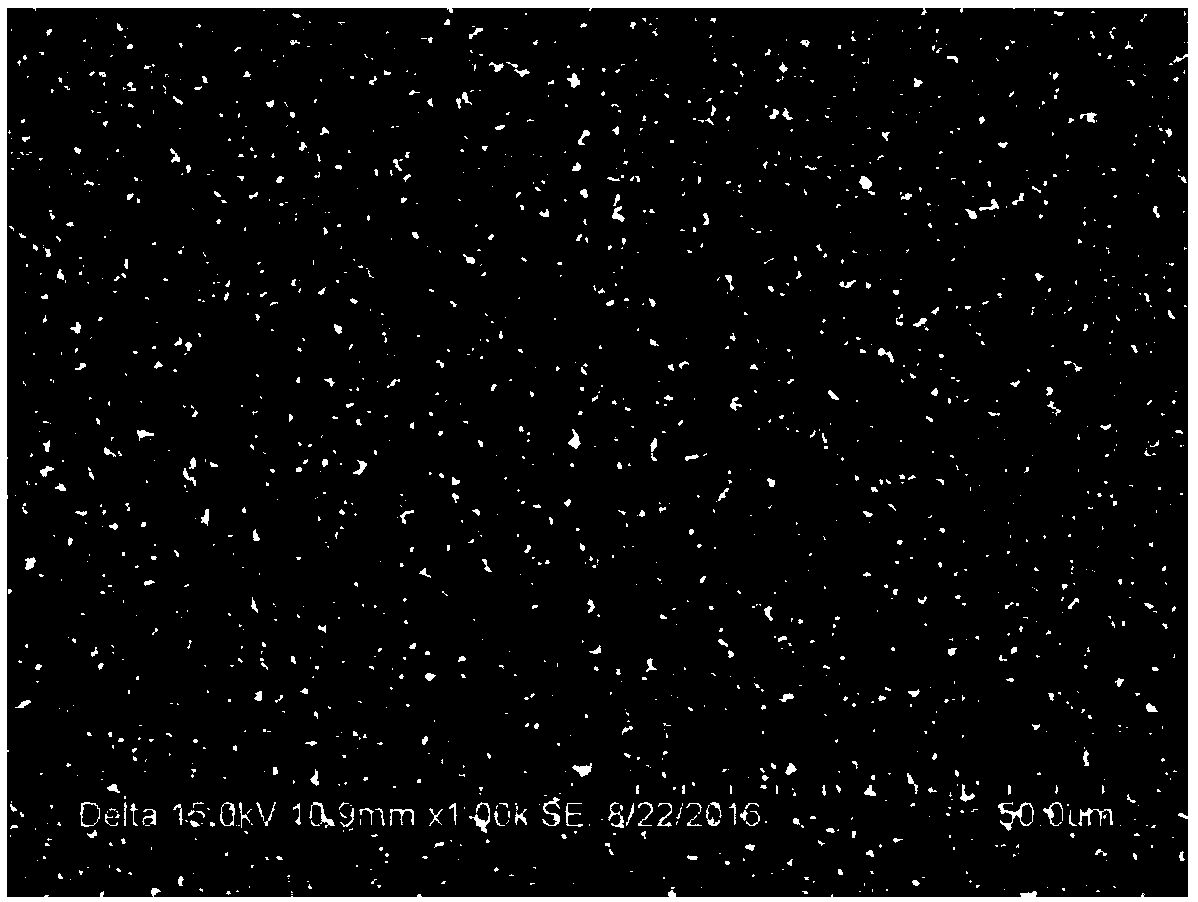

Image

Examples

Embodiment 1

[0046] An oxygen-free copper surface oxidation-dissolution superhydrophilic treatment process, comprising the following steps:

[0047] (1) Preparation of treatment solution

[0048] Weigh a certain amount of oxalic acid solid, dissolve the oxalic acid solid in deionized water to form an oxalic acid solution, and then add an appropriate amount of oxidant hydrogen peroxide to the oxalic acid solution to obtain a mixed solution of 0.1 wt% oxalic acid and 0.2 wt% hydrogen peroxide as a treatment liquid.

[0049] (2) Oxygen-free copper surface pretreatment

[0050] The oxygen-free copper surface is pretreated by ultrasonic cleaning with a mixed solution of surfactant sodium dodecylsulfonate and strong alkali sodium hydroxide, and then cleaned with deionized water.

[0051] (3) Oxygen-free copper surface oxidation-dissolution treatment

[0052] Immerse the oxygen-free copper pretreated in step (2) into the treatment solution prepared in step (1), and perform ultrasonic cleaning ...

Embodiment 2

[0055] An oxygen-free copper surface oxidation-dissolution superhydrophilic treatment process, comprising the following steps:

[0056] (1) Preparation of treatment solution

[0057] Weigh a certain amount of acetic acid liquid, mix the acetic acid liquid in deionized water to form an acetic acid solution, then add a suitable amount of oxidant hydrogen peroxide and an appropriate amount of hydrogen peroxide stabilizer ethylene glycol to the acetic acid solution to obtain 4.5wt% concentration of acetic acid and hydrogen peroxide A mixed solution with a concentration of 5 wt% was used as a treatment solution.

[0058] (2) Oxygen-free copper surface pretreatment

[0059] The oxygen-free copper surface is pretreated with a mixed solution of surfactant polyvinyl alcohol and strong alkali potassium hydroxide, which is shaken and cleaned, and then cleaned with deionized water.

[0060] (3) Oxygen-free copper surface oxidation-dissolution treatment

[0061] Immerse the oxygen-free ...

Embodiment 3

[0064] An oxygen-free copper surface oxidation-dissolution superhydrophilic treatment process, comprising the following steps:

[0065] (1) Preparation of treatment solution

[0066] Take a certain amount of hydrochloric acid liquid, dissolve the hydrochloric acid liquid in deionized water to form a hydrochloric acid solution, then add an appropriate amount of oxidizing agent hypochlorous acid to the hydrochloric acid solution, and obtain the hydrochloric acid 0.1wt% concentration and the hypochlorous acid 0.1wt% concentration The mixed solution was used as a treatment solution.

[0067] (2) Oxygen-free copper surface pretreatment

[0068] The oxygen-free copper surface is pretreated by ultrasonic cleaning with a mixed solution of surfactant C9-11 alkanol polyether and alkali triethanolamine, and then cleaned with deionized water.

[0069] (3) Oxygen-free copper surface oxidation-dissolution treatment

[0070] The oxygen-free copper pretreated in step (2) is immersed in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com