A kind of manufacture method of anion exchange alloy membrane

A manufacturing method and cation exchange technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of easy adhesion of pollutants, reduced anti-pollution ability, and uneven membrane surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

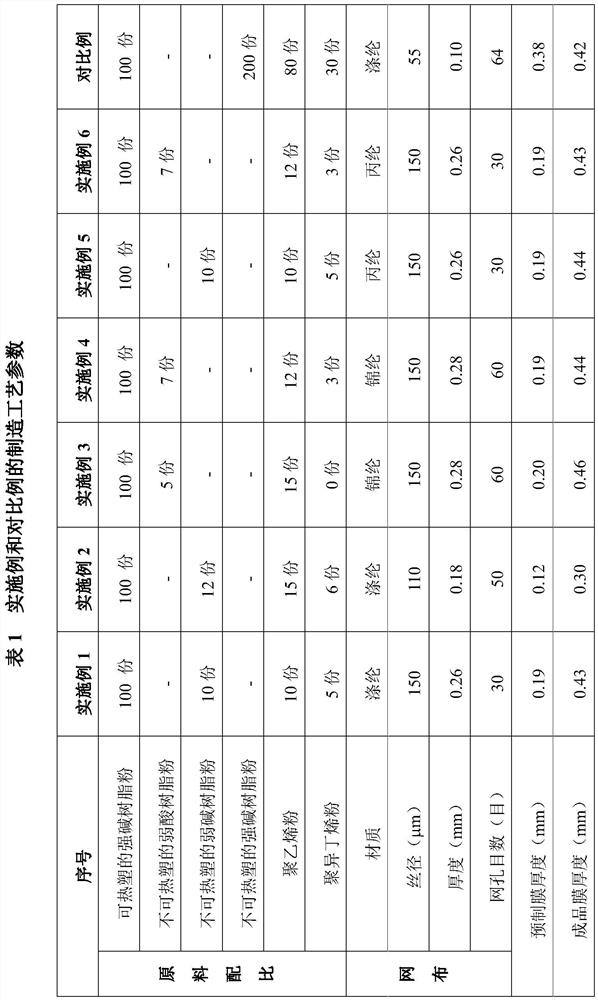

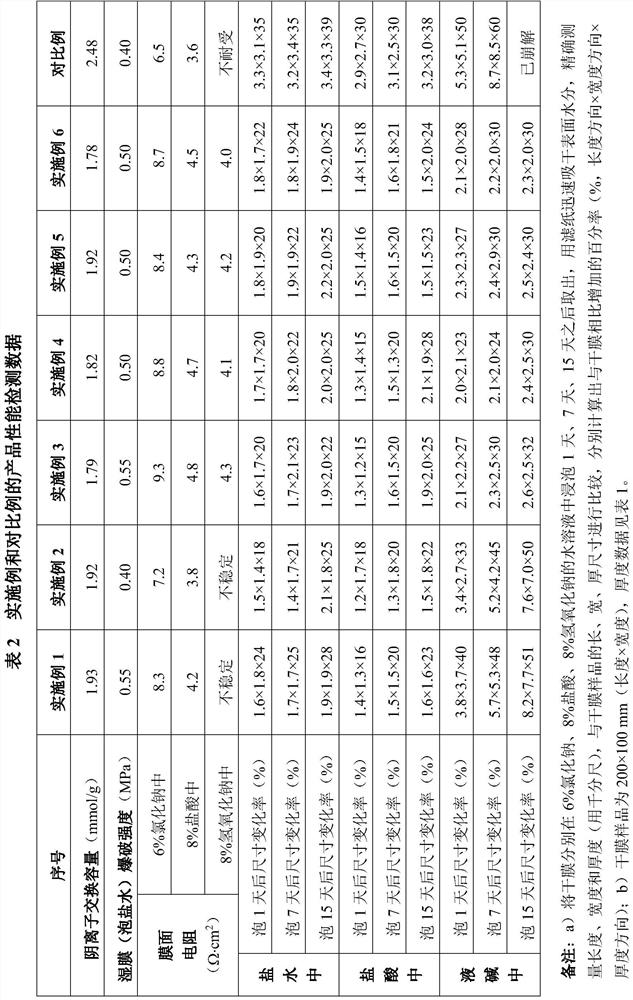

Embodiment 1

[0022]Preparation of raw materials: 1) thermoplastic strong base resin powder (polyethylene-quaternized polystyrene strong base anion exchange resin powder): it can be prepared by referring to the method described in the literature (Chinese invention patent application number 201510569663.X) Obtained, provided by Hangzhou Er Environmental Protection Technology Co., Ltd. (the particle size is below 50 mesh, and the anion exchange capacity is 2.53mmol / g dry basis). 2) Non-thermoplastic weak base resin powder: epoxy series weak base anion exchange resin (particle size range 0.325-1.25mm, anion exchange capacity 7.5mmol / g dry basis, model 335, manufactured by Shanghai Huazhen Customized by Technology Co., Ltd.), soaked in 4% hydrochloric acid, washed with water until neutral, that is, converted to chlorine form, and dried to constant weight at 60-70°C; first crushed with a jet mill until it can pass through a 100-mesh stainless steel screen, Grinding with a ball mill for 6 hours; ...

Embodiment 2

[0026] The model in embodiment 1 is the epoxy series weak base resin of 335, changes the model into the styrene series weak base resin of 301 (the particle diameter scope is 0.325~1.25mm, and anion exchange capacity is 5.2mmol / g, by Shanghai Customized by Huazhen Science and Technology Co., Ltd.); "3 kilograms of non-thermoplastic weak base resin powder, 3 kilograms of polyethylene powder, and 1.5 kilograms of polyisobutylene powder" in Example 1 are replaced with "3.6 kilograms of non-thermoplastic (301 ) Weak base resin powder, 4.5 kilograms of polyethylene powder, 1.8 kilograms of polyisobutylene powder "; The polyester mesh cloth that the model is DPP12S is changed into the polyester mesh cloth that the model is DPP20S (purchased from Shanghai Xintie Chain Screen Mesh Manufacturing Co., Ltd.) The rest of the raw materials and alloy film manufacturing process are unchanged compared with Example 1 (see Table 1 for details), and the prefabricated diaphragm with a thickness of ...

Embodiment 3

[0029] With the model in embodiment 1 being 335 epoxy series weak base resins, change the model into 122 phenolic series weak acid resins (the particle size range is 0.325~1.25mm, and the cation exchange capacity is 4.2mmol / g, by Tianxing, Bengbu City Resin Co., Ltd. customizes); "3 kilograms of non-thermoplastic weak base resin powder, 3 kilograms of polyethylene powder, 1.5 kilograms of polyisobutylene powder" in embodiment 1 are replaced with "1.5 kilograms of non-thermoplastic (122) weak acid Resin powder, 4.5 kilograms of polyethylene powder (do not add polyisobutylene powder) "; Change the polyester mesh cloth that model is DPP12S into the nylon mesh cloth that model is JPP24 (purchased from Shanghai Xintie Chain Screen Mesh Manufacturing Co., Ltd.); the rest The raw materials and alloy film manufacturing process are unchanged compared with Example 1 (see Table 1 for details). A prefabricated diaphragm with a thickness of 0.20 mm is prepared earlier, and an alloy film pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com