Magnetic flocculation enhanced membrane integration device for oil sand tailing wastewater and treatment method for oil sand tailing wastewater

A wastewater treatment and integrated device technology, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problem of high coagulant dosage, solve a large number of water pollution problems, realize Sewage reuse and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

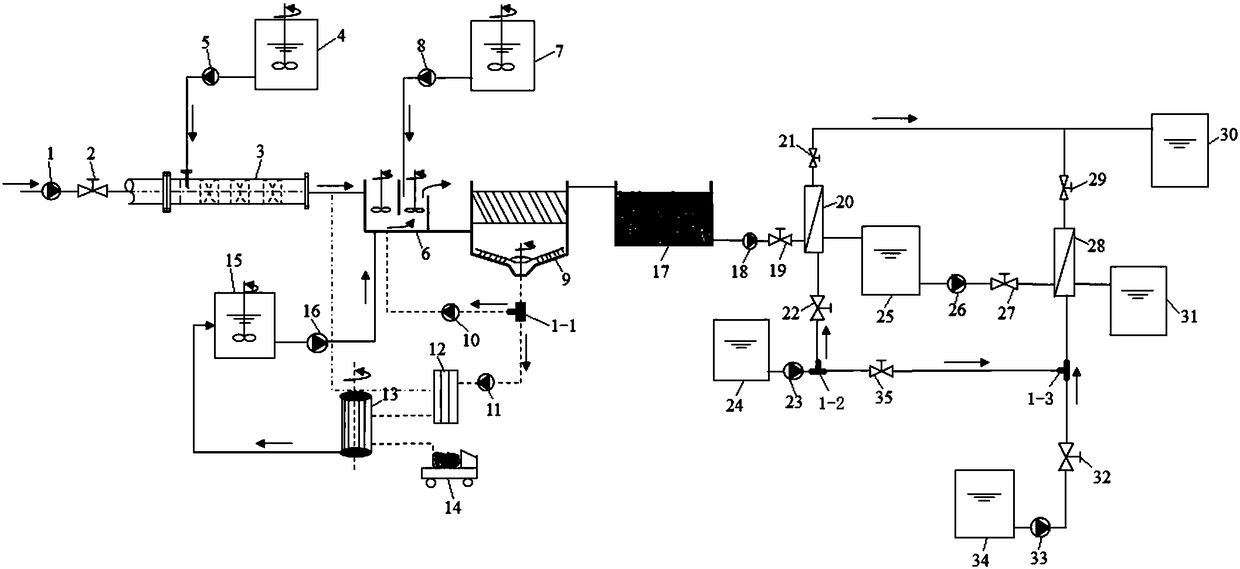

[0044] Specific implementation mode one: combine figure 1 This embodiment is described. The magnetic flocculation enhanced membrane integration device used in the treatment of oil sand tailings wastewater in this embodiment includes a raw water pump 1, a static pipeline mixer 3, a coagulant medicine box 4, a coagulation dosing pump 5, and a flocculation tank 6. Coagulation aid kit 7, coagulation aid dosing pump 8, sedimentation tank 9, sludge return pump 10, sludge booster pump 11, sludge dehydration device 12, magnetic powder recovery device 13, sludge transport device 14 , Magnetic powder dosing box 15, magnetic powder dosing pump 16, filter tank 17, ultrafiltration booster pump 18, ultrafiltration membrane device 20, cleaning pump 23, cleaning agent medicine box 24, ultrafiltration water production tank 25, nanofiltration booster Pump 26, nanofiltration membrane device 28, waste water tank 30, nanofiltration water production tank 31, nanofiltration dosing pump 33 and scale ...

specific Embodiment approach 2

[0049] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the water quality characteristics of the oil sand tailings wastewater are: pH=6.4-8.3, turbidity=165.4-220.7NTU, TOC=42.3-63.5mg / L , COD=195.7-278.8mg / L, naphthenic acid=17.9-28.5mg / L, conductivity=2956.2-3988.5μS / cm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0050] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the coagulant used in the coagulant medicine box 4 is a metal salt coagulant, specifically polyaluminum chloride, polysulfuric acid One or more of iron, ferric chloride, ferrous sulfate, polyaluminum ferric chloride, and aluminum sulfate in any proportion. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Turbidity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com