Universal two-electrode modified electrode unit and preparation method and application thereof

A technology for modifying electrodes and electrodes, which is applied in the field of electrochemical analysis and detection to achieve excellent electrocatalytic activity and stability, simple operation, good sensitivity and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

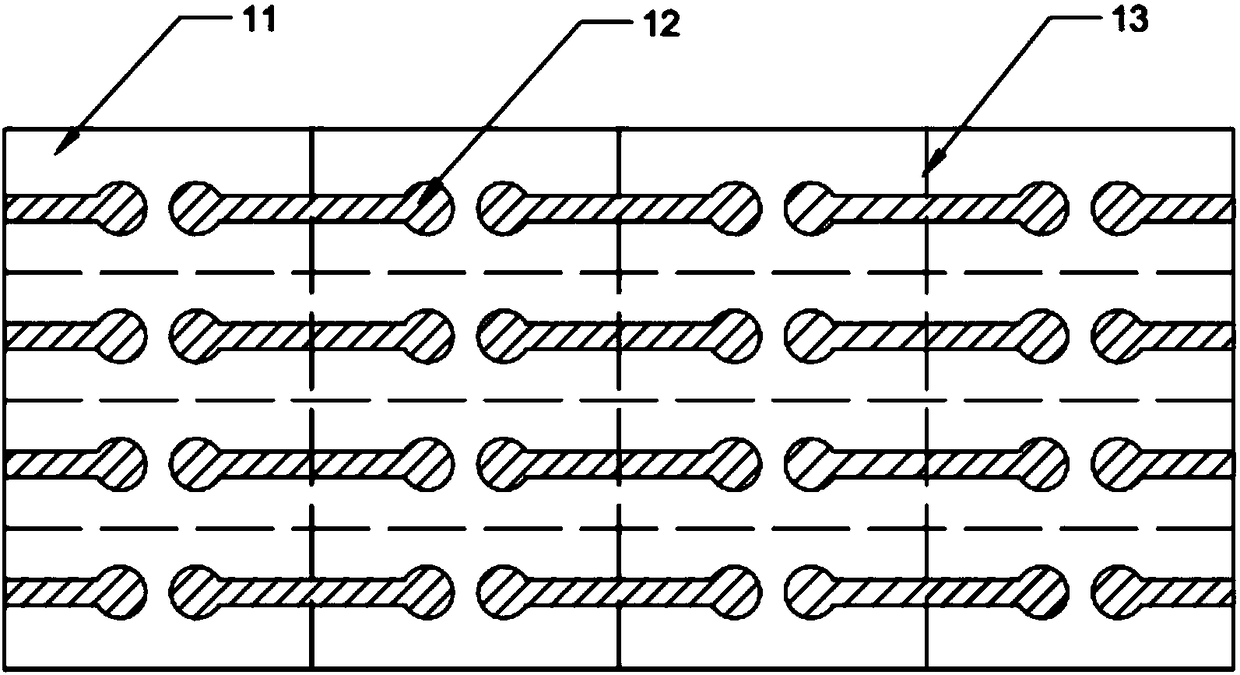

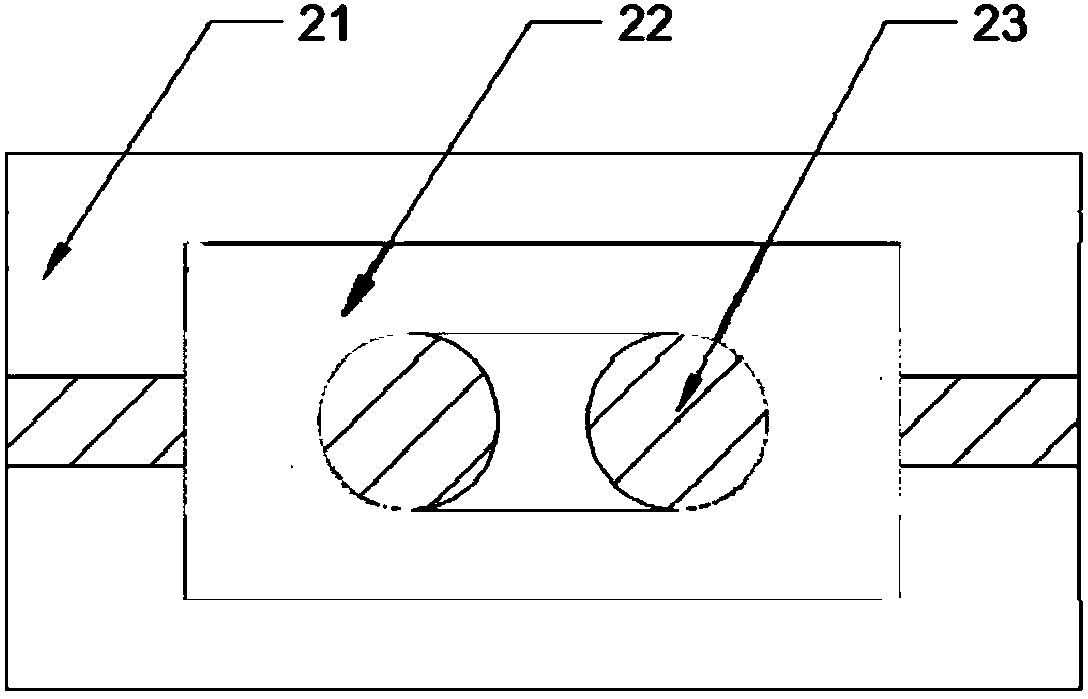

[0039] This embodiment is aimed at the small-batch preparation of electrode units, which is achieved through the following technical solutions, including etching and cutting of electrode units, fabrication of liquid storage pools, protective modification of cathodes of electrode units and modification of anodes. In this embodiment, indium tin oxide conductive glass (ITO) is selected as the electrode substrate, and electrodeposited gold nanomaterials are selected as the inert metal modified cathode, so as to figure 1 Take the etching pattern as an example to make electrode units.

[0040] (1) The ITO electrode is etched by photolithography, which needs to go through the steps of cleaning, glue coating, pre-baking, exposure, development, etching, glue removal and inspection. details as follows:

[0041] (1.1) Sonicate the ITO electrode sheet with acetone, absolute ethanol and distilled water for 10 minutes respectively, rinse with distilled water and dry for later use.

[0042] ...

Embodiment 2

[0057] This embodiment is aimed at the small-batch preparation of electrode units, and the technical solution is the same as that of Embodiment 1. In this embodiment, indium tin oxide conductive glass (ITO) is selected as the electrode substrate, and electrodeposited gold nanomaterials are selected as the inert metal-modified cathode.

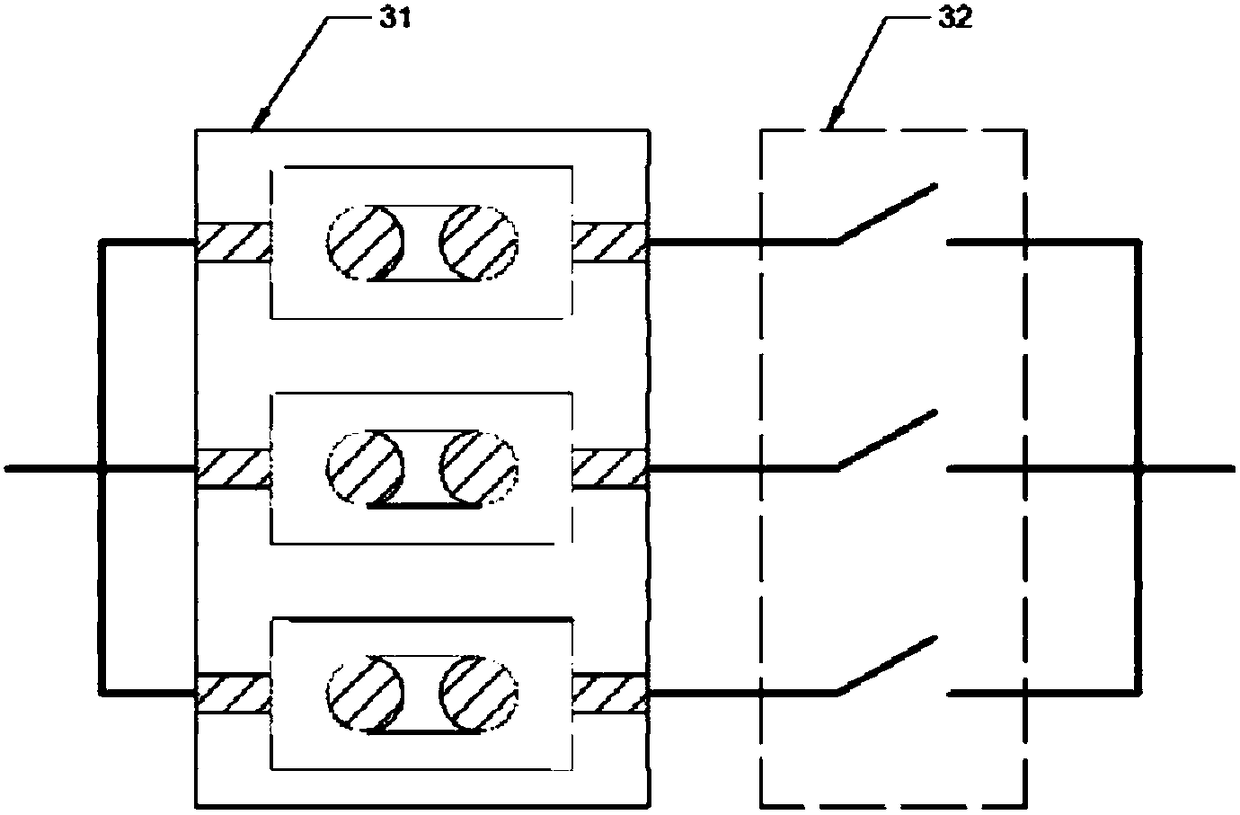

[0058] ITO etching method is identical with embodiment 1 step (1), obtains figure 1 After the pad shown, press the image 3 Cut into an array chip 31 with three electrode units connected in parallel, and make a liquid storage pool according to step (2) of Embodiment 1. After connecting three electrode units in parallel, the cathode and anode modification were carried out. The anode modification selected graphite oxide buffer solution with a concentration of 0.01 mg / mL (the buffer solution was 0.5 M phosphate buffer, pH 8), and the scanning potential was 0 V~-1.0 V , the scanning speed is 1000 mV / s, scanning 50 circles, the other is the same a...

Embodiment 3

[0061] This embodiment is aimed at the small-batch preparation of electrode units, and the technical solution is the same as that of Embodiment 1. In this embodiment, indium tin oxide conductive glass (ITO) is selected as the electrode substrate, and electrodeposited gold nanomaterials are selected as the inert metal-modified cathode.

[0062] ITO etching method is identical with embodiment 1 step (1), obtains figure 1 After the electrode sheets shown, and according to step (2) of Example 1, a liquid storage pool was made. Graphite oxide buffer solution with a concentration of 1 mg / mL (0.2 M phosphate buffer, pH 6.5) was used for anode modification. circle, the others are the same as step (3) of embodiment 1. After connecting two electrode units in series, we can get Figure 4 The isolated bipolar electrode chip shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com