Catalyst for preparing phthalic anhydride as well as preparation method and application thereof

A catalyst, phthalic anhydride technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unmentioned catalyst life, hot spot temperature, etc., to maintain catalyst performance, prolong catalyst life, The effect of improving activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

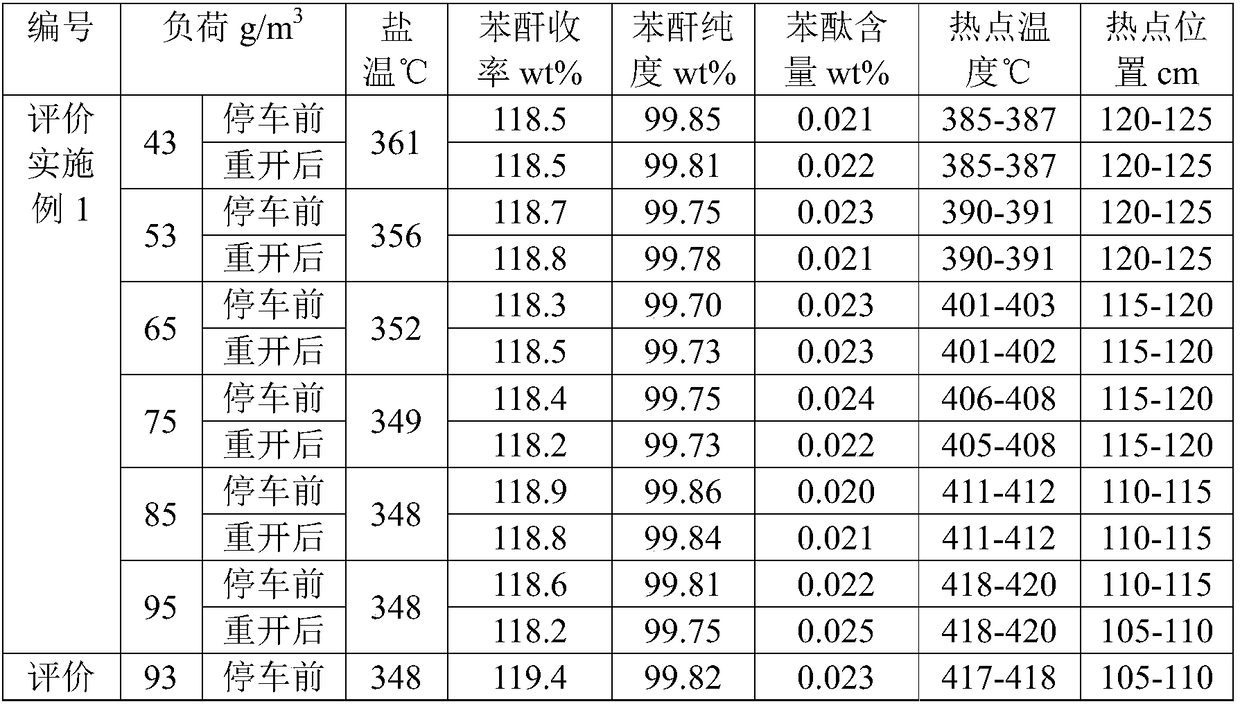

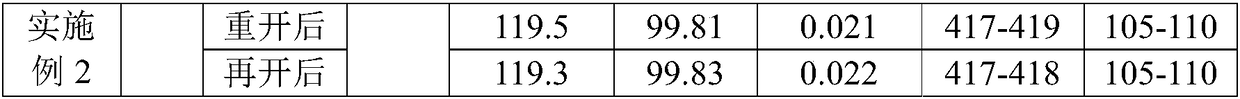

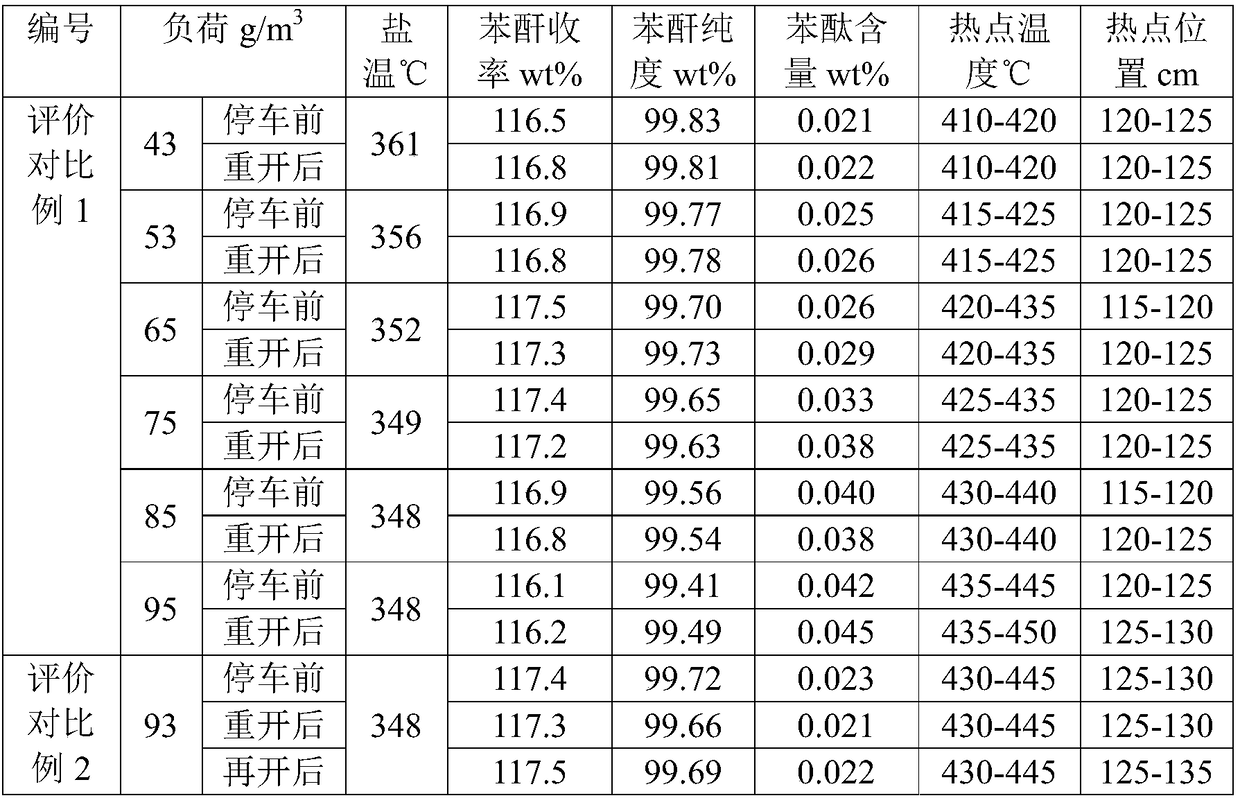

Examples

Embodiment 1

[0035] Carrier treatment: The carrier is a talc ring with an outer diameter of 7*7*4mm. The carrier is screened, washed with deionized water, and dried for later use.

[0036] Slurry preparation:

[0037] (1) Add 2.50 g of tungsten phosphate to 700 mL of 50% ethanol aqueous solution, then add 0.28 g of cesium carbonate dropwise, and stir for 12 hours at room temperature.

[0038] (2) Add 17.1g vanadyl oxalate to the solution prepared in (1), then add 6.58g silver nitrate, 158g titanium dioxide, 10g organic binder (acrylic acid:maleic acid=3:1, weight ratio, other Embodiment is the same) and 120mL formamide. Stir evenly, and use a homogenizing pump to homogenize at 4000 rpm for 30 minutes to form a suspension.

[0039] Spray drying:

[0040] Put the treated 1000g carrier into the spraying machine, heat the carrier to 105°C by hot air, start spraying, and control the temperature during spraying to 110°C. After the slurry is atomized, it is sprayed onto the turning carrier. ...

Embodiment 2

[0046] The preparation method is the same as in Example 1, and the amounts of each component are respectively: 750 ml of 50% ethanol aqueous solution, 6.54 g of phosphomolybdic acid, 1.68 g of cesium carbonate, 20.3 g of vanadyl oxalate, 15.0 g of silver nitrate, 168 g of titanium dioxide, and 168 g of trichloride 0.1g of iron, 0.5g of antimony trioxide, 2.0g of stannous chloride, 11g of binder, and 120ml of formamide. Catalyst product B was obtained.

Embodiment 3

[0050] The preparation method is the same as in Example 1, and the amounts of each component are: 800ml of 50% ethanol aqueous solution, 7.8g of phosphotungstic acid, 4.77g of phosphomolybdic acid, 2.36g of cesium carbonate, 26.0g of vanadyl oxalate, 180g of titanium dioxide, and 0.5 g of iron oxide, 1.0 g of antimony trioxide, 1.0 g of stannous chloride, 12 g of binder, and 120 ml of formamide. Catalyst product C was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com