Pervious concrete for roads and production process thereof

A permeable concrete and road technology, applied in the field of concrete, can solve the problems of large porosity of porous concrete, reduced compressive strength, and reduced service life of concrete, and achieve the effect of improving water permeability, increasing strength, and reasonable proportioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

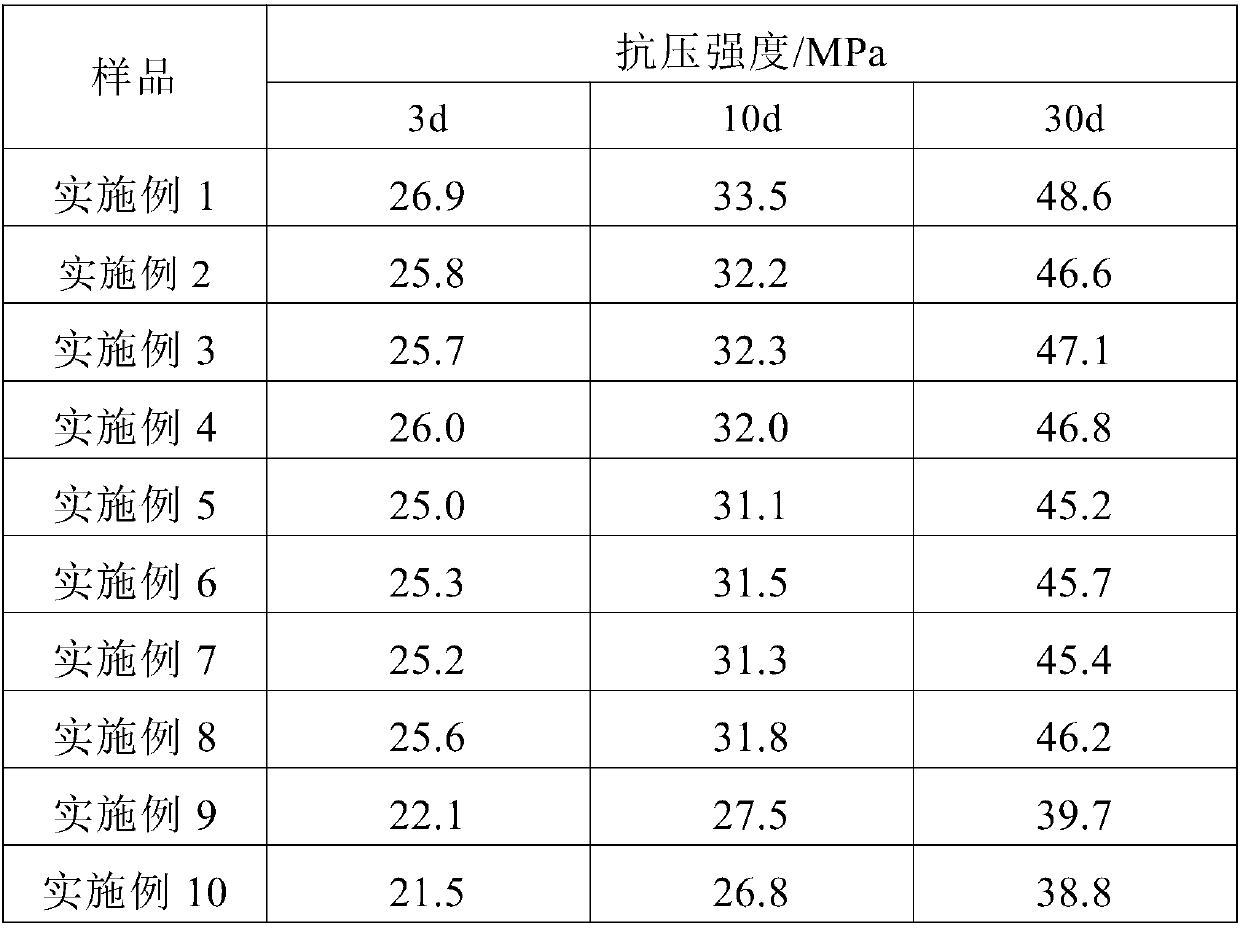

Examples

Embodiment 1

[0061] A permeable concrete for roads, comprising the following raw materials in parts by weight: 55 parts of cement, 200 parts of limestone gravel, 80 parts of yellow sand, 80 parts of quartz sand, 30 parts of water, 14 parts of fly ash, 14 parts of silica fume, 6-hydroxy - 3 parts of sodium naphthalenesulfonate, 15 parts of nano-silica dispersion, 6 parts of waterproofing agent, 1 part of p-toluenesulfonyl hydrazide, 1 part of azodicarbonamide, SiO 2 1 part of modified 4,4'-oxobisbenzenesulfonyl hydrazide.

[0062] The waterproofing agent is a mixture of perfluorohexanesulfonate potassium, isopropyl myristate, and water glass polyurethane composite material, and the perfluorohexane sulfonate potassium, isopropyl myristate, water glass polyurethane composite material The mass ratio is 1:1:1.

[0063] The preparation method of the water glass polyurethane composite material is as follows: firstly weigh water glass, 4,4'-diphenylmethane diisocyanate, polytetrahydrofuran diol, ...

Embodiment 2

[0072] It is basically the same as Example 1, the difference is only that: the water repellent is a mixture of potassium perfluorohexanesulfonate and isopropyl myristate, and the mixture of potassium perfluorohexanesulfonate and isopropyl myristate The mass ratio is 1:1.

Embodiment 3

[0074] Substantially the same as Example 1, the difference is only that: the waterproofing agent is a mixture of isopropyl myristate and water glass polyurethane composite material, and the mass ratio of said isopropyl myristate and water glass polyurethane composite material is 1 :1.

[0075] The preparation method of the water glass polyurethane composite material is as follows: firstly weigh water glass, 4,4'-diphenylmethane diisocyanate, polyether polyol, di Dibutyltin laurate, epoxidized soybean oil acrylate and diisononyl cyclohexane-1,2-dicarboxylate, then water glass, polytetrahydrofuran diol and dibutyltin dilaurate at 40°C and 200r / min Stir at low temperature for 30 minutes, and mix well to obtain component A; then 4,4' diphenylmethane diisocyanate, epoxidized soy acrylate, cyclohexane-1,2-diisononyl dicarboxylate at 40°C 200r / min under the condition of stirring for 25min to obtain component B; keeping the temperature and rotating speed constant, mix components A an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com