Visco-elastic acid-based fracturing fluid and preparation method thereof

A fracturing fluid and viscoelastic technology, which is applied in the field of viscoelastic acid-based fracturing fluid and its preparation, can solve problems such as the inability to reduce the damage of polymers to formations, and achieve improved seepage capacity, increased acidification range, and high viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides an acid-based fracturing fluid, in terms of mass percentage:

[0041] Thickener: Dioctadecyldimethylammonium chloride 7.5wt.%

[0042] 31wt.% concentrated hydrochloric acid: 50.0wt.%

[0043] Counter ion salt: sodium lauryl sulfate 0.5wt.%

[0044] Corrosion inhibitor: bicyclic imidazoline 0.5wt.%

[0045] Iron ion stabilizer: EDTA sodium salt iron ion stabilizer 1.5wt.%

[0046] The balance is water.

[0047] The specific preparation process is:

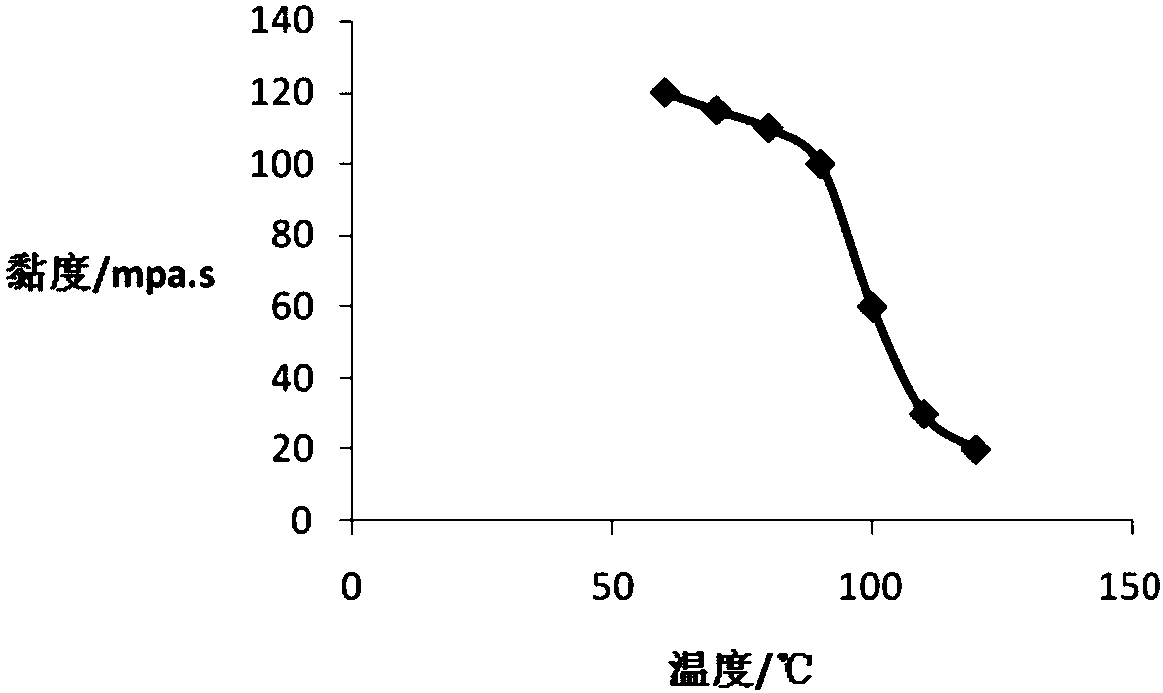

[0048] According to the above ratio, dioctadecyl dimethyl ammonium chloride was added into water to fully dissolve at room temperature, and the corrosion inhibitor bicyclic imidazoline 3, ethylenediaminetetraacetic acid sodium salt iron ion stabilizer, 31wt.% Concentrated hydrochloric acid to obtain an acidic thickener solution, the counter ion salt sodium lauryl sulfate was dissolved in water, and then the two solutions were mixed and stirred evenly to obtain a viscoelastic acid-based fracturing...

Embodiment 2

[0064] This embodiment provides an acid-based fracturing fluid, in terms of mass percentage:

[0065] Thickener: lauryl amidopropyl betaine 7.5wt.%

[0066] 37wt.% concentrated hydrochloric acid: 50wt.%

[0067] Counter ion salt: Potassium chloride 2.5wt.%

[0068] Corrosion inhibitor: imidazoline oleate 2.5wt.%

[0069] Iron ion stabilizer: erythorbate iron ion stabilizer 4.5wt.%

[0070] The balance is water.

[0071] The specific preparation process is:

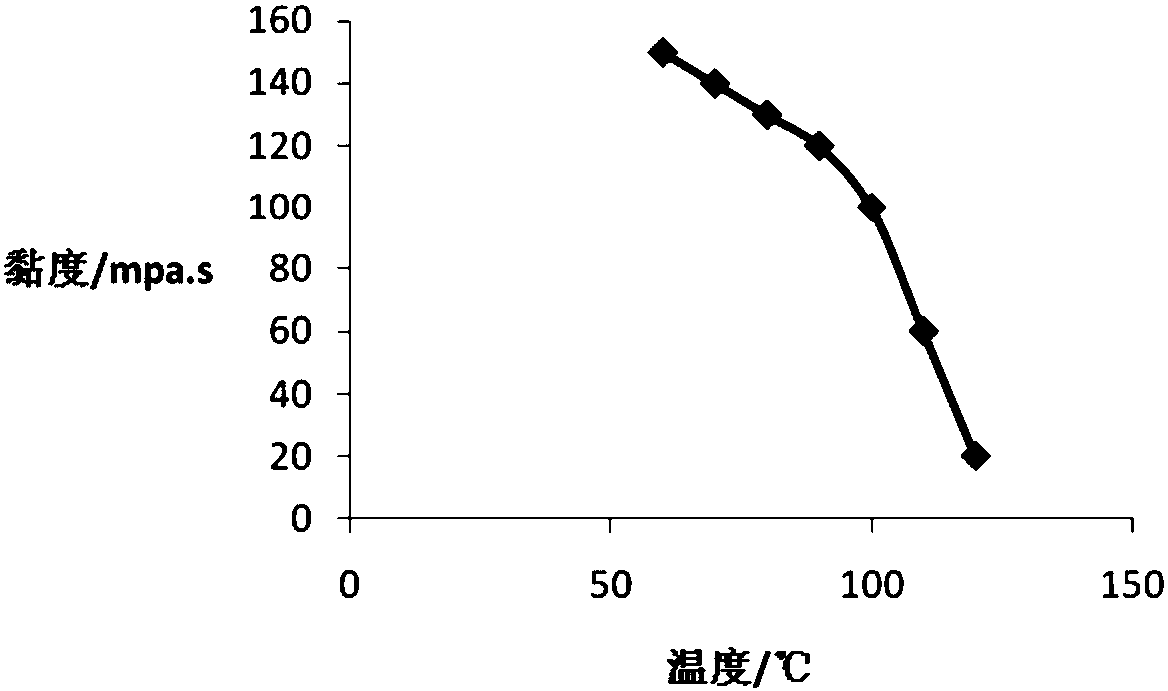

[0072] According to the above proportions, under normal temperature, lauryl amidopropyl betaine is added into water to fully dissolve, and the corrosion inhibitor oleic acid imidazoline, erythorbate iron ion stabilizer, and 37wt.% concentrated hydrochloric acid are added successively to obtain an acidic thickener solution. The ionic salt potassium chloride was dissolved in water, and then the two solutions were mixed and stirred evenly to obtain a viscoelastic acid-based fracturing fluid system. The data are shown in ...

Embodiment 3

[0088] This embodiment provides an acid-based fracturing fluid, in terms of mass percentage:

[0089] Thickener: Behenyltrimethylammonium Chloride 4wt.%

[0090] 31wt.% concentrated hydrochloric acid: 75.0wt.%

[0091] Counter ion salt: sodium benzoate 2.5wt.%

[0092] Corrosion inhibitor: bromide-1,4(a-octylpyridine)butane 2.5wt.%

[0093] Iron ion stabilizer: ferric citrate stabilizer 5.0wt.%

[0094] The balance is water.

[0095] The specific preparation process is:

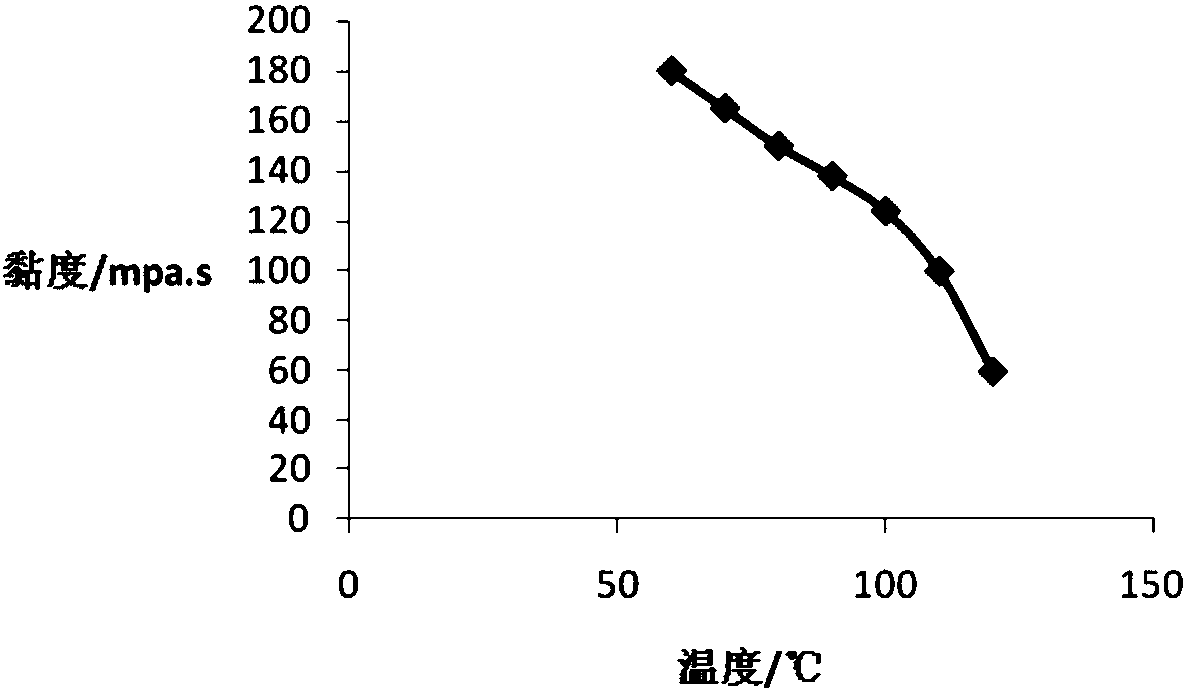

[0096] According to the above ratio, add behenyltrimethylammonium chloride into water to fully dissolve at room temperature, and then add corrosion inhibitor bromide-1,4(a-octylpyridine)butane and ferric citrate ion to stabilize % concentrated hydrochloric acid to obtain an acidic thickener solution, the counter ion salt sodium benzoate was dissolved in water, and then the two solutions were mixed and stirred evenly to obtain a viscoelastic acid-based fracturing fluid system. The data are shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com