Carbon nanotube-supported catalyst applicable to oxidizing atmosphere and preparation method thereof

A technology of supported catalysts and carbon nanotubes, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve uniform dispersion, good stability, good activity and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh 1g of carbon nanotubes (outer diameter 10-20nm, length 10-30μm, specific surface area 210m 2 / g) was added to the mixture of 200ml concentrated sulfuric acid and 100ml concentrated nitric acid, ultrasonically dispersed for 10min, then refluxed at 60°C for 10h under stirring, washed and filtered, washed with water until the pH value of the filtrate was neutral, and dried at 60°C for 24h. A pretreated carbon nanotube carrier is obtained. Measure 3ml of ethanol solution of chloropalladium-platinic acid with a concentration of 2.7mg / mlPd and 1.4mg / mlPt, add the pretreated carbon nanotube carrier, stir evenly, then dry at 60°C for 24h, and then dry the dried The product was calcined at 500°C for 2 hours to obtain a 0.8wt%Pd-0.4wt%Pt / MWNTs catalyst.

Embodiment 2

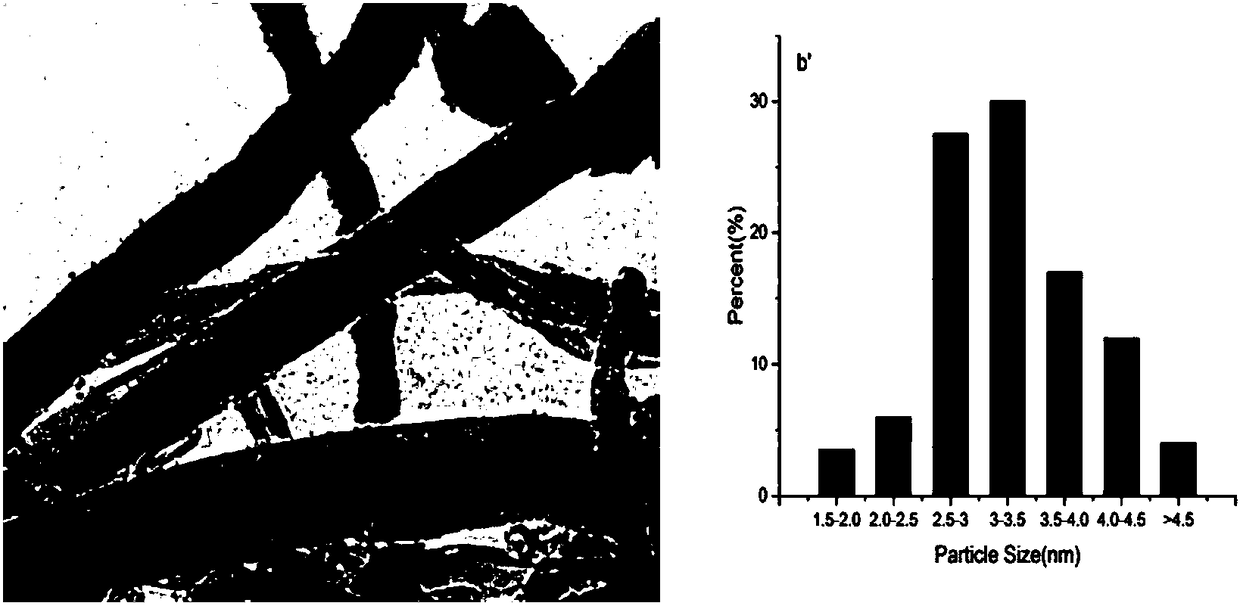

[0044] Weigh 1g of carbon nanotubes (outer diameter 20-30nm, length 10-20μm, specific surface area 110m 2 / g) was added to the mixture of 100ml concentrated sulfuric acid and 100ml concentrated nitric acid, ultrasonically dispersed for 5min, then refluxed at 80°C for 3h under stirring, washed and filtered, washed with water until the pH value of the filtrate was neutral, and dried at 100°C for 18h. A pretreated carbon nanotube carrier is obtained. Measure 2ml of the acetone solution of palladium chloride-platinic acid with a concentration of 10.41mg / ml Pd and 5.21mg / ml Pt, add the pretreated carbon nanotube carrier, stir evenly, then dry at 80°C for 20h, and then dry The product was calcined at 200°C for 4h to obtain a noble metal 2wt%Pd-1wt%Pt / MWNTs catalyst. figure 2 It is the transmission electron microscope photo of the catalyst and the particle size distribution diagram of the noble metal. It can be seen from the figure that the active components of the noble metal are ...

Embodiment 3

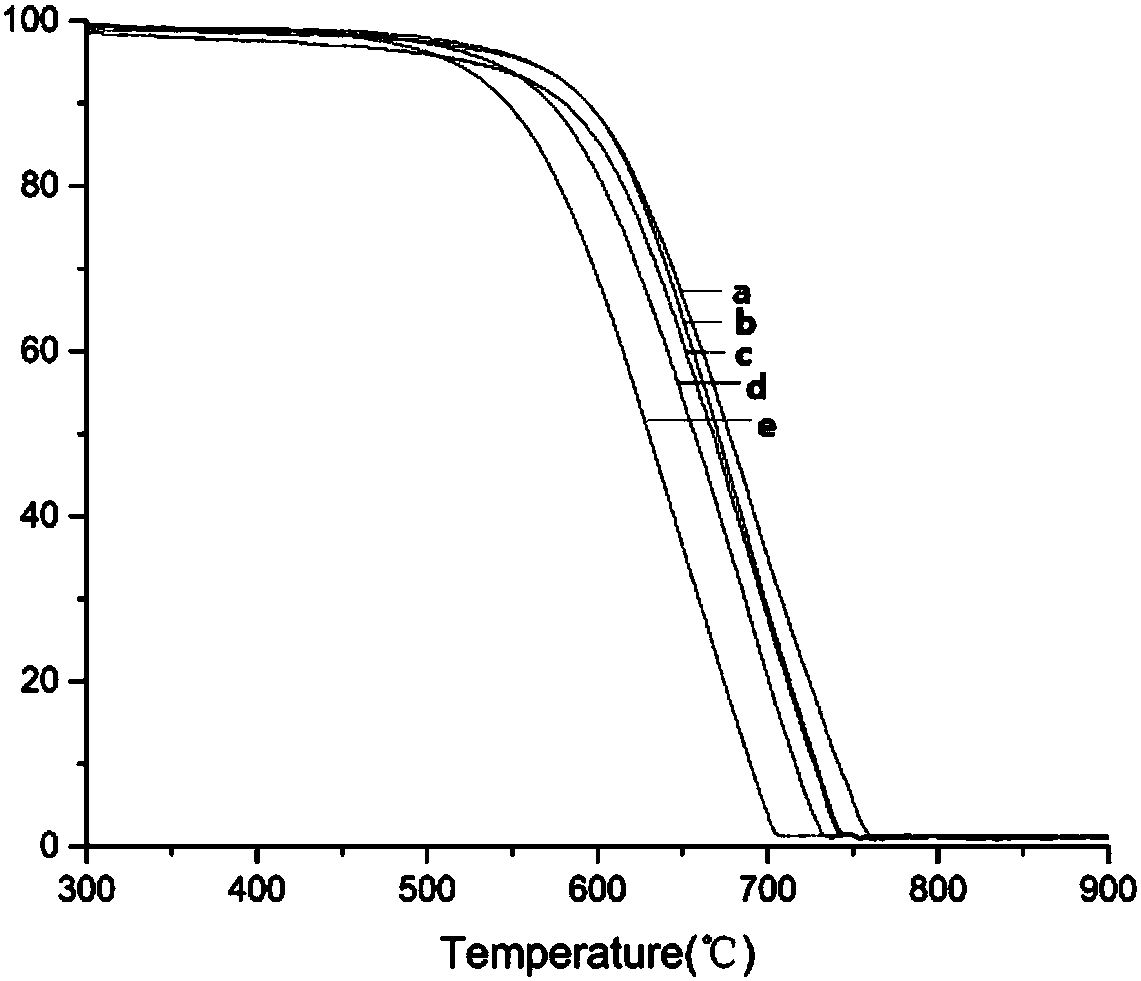

[0046] Weigh 1g of carbon nanotubes (outer diameter 30-50nm, length 10-20μm, specific surface area 80m 2 / g) was added to a mixture of 25ml of concentrated sulfuric acid and 25ml of concentrated nitric acid, ultrasonically dispersed for 30min, then refluxed at 120°C for 3h under stirring, washed and filtered, washed with water until the pH value of the filtrate was neutral, and dried at 120°C for 12h. A pretreated carbon nanotube carrier is obtained. The thermogravimetric curves of the carbon nanotubes before and after treatment are respectively figure 1 e and figure 1 d, By comparison, it can be seen that before pretreatment, the temperature at which MWCNTs begin to lose weight is about 500 °C, and after pretreatment, this temperature rises to 550 °C, that is, the thermal stability of MWCNTs is significantly enhanced after acid treatment. This is because the raw material MWCNTs has amorphous carbon on the surface and catalyst residues in the tube, both of which will reduce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com