Method for treating wastewater containing heavy metal ions through phase transformation of MgCO3.3H2O

A technology of heavy metal ions and magnesium carbonate trihydrate, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that sediments are difficult to be effectively treated, and achieve good filtration performance, Good wettability, simple and operable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

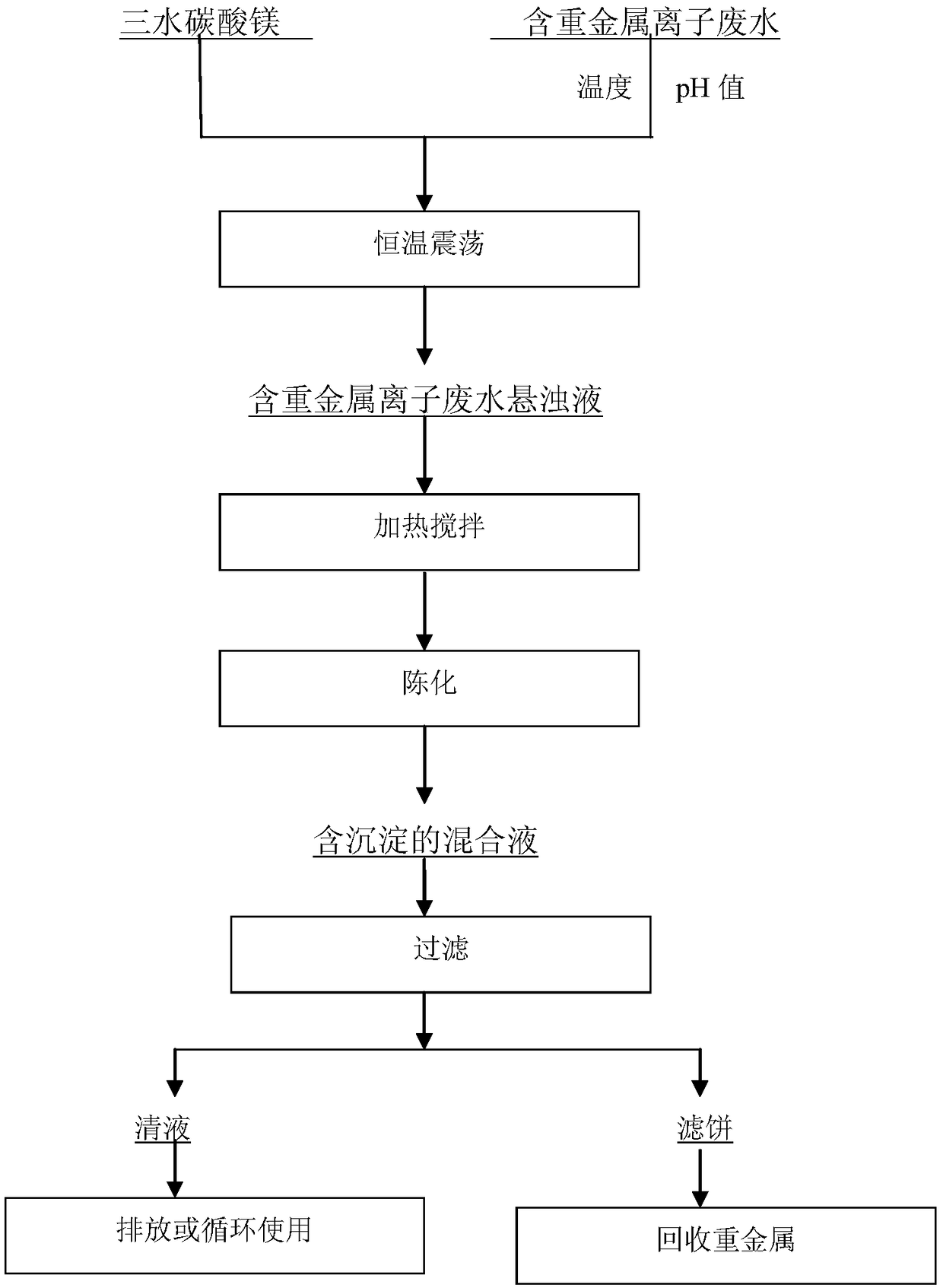

[0039] A method for treating waste water containing heavy metal ions by phase transition of magnesium carbonate trihydrate, the flow chart of which is shown in figure 1 , including the following steps:

[0040] Step 1, the preparation of magnesium carbonate trihydrate

[0041] (1) Insulate magnesite at 750°C for 3.5 hours, and air-cool to room temperature to obtain highly active magnesium oxide;

[0042] (2) Using highly active magnesium oxide as a raw material, according to the solid-to-liquid ratio of 1:40, mix it with deionized water at 90°C, and hydrate at 60°C for 3.5h to obtain Mg(OH) 2 suspension.

[0043] (3) After cooling to room temperature, to Mg(OH) 2 0.16m in suspension 3 / L rate into CO 2 Gas, until the pH value of the solution is 7.3 to 7.8, stop the ventilation, and get heavy magnesium water Mg (HCO 3 ) 2 solution.

[0044] (4) the above-mentioned gained heavy magnesium water Mg (HCO 3 ) 2 The solution was stirred and reacted at 45° C. at a rate of 45...

Embodiment 2

[0057] A method for treating waste water containing heavy metal ions by phase transformation of magnesium carbonate trihydrate, comprising the following steps:

[0058] Step 1, the preparation of magnesium carbonate trihydrate

[0059] (1) Insulate magnesite at 750°C for 3.5 hours, and air-cool to room temperature to obtain highly active magnesium oxide;

[0060] (2) Using magnesium oxide as a raw material, according to the solid-to-liquid ratio of 1:40, mix it with deionized water at 90°C, and hydrate at 60°C for 3.5h to obtain Mg(OH) 2 suspension.

[0061] (3) After cooling to room temperature, to Mg(OH) 2 0.14m in suspension 3 / L rate into CO 2 Gas, until the pH value of the solution is 7.3 to 7.8, stop the ventilation, and get heavy magnesium water Mg (HCO 3 ) 2 solution.

[0062] (4) the above-mentioned gained heavy magnesium water Mg (HCO 3 ) 2 The solution was stirred and reacted at 50°C at a rate of 500r / min for 1.0h, the stirring was stopped, filtered, washed...

Embodiment 3

[0075] A method for treating waste water containing heavy metal ions by phase transformation of magnesium carbonate trihydrate, comprising the following steps:

[0076] Step 1, the preparation of magnesium carbonate trihydrate

[0077] (1) Insulate magnesite at 750°C for 3.5 hours, and air-cool to room temperature to obtain highly active magnesium oxide;

[0078](2) Using highly active magnesium oxide as a raw material, according to the solid-to-liquid ratio of 1:40, mix it with deionized water at 90°C, and hydrate at 60°C for 3.5h to obtain Mg(OH) 2 suspension.

[0079] (3) After cooling to room temperature, to Mg(OH) 2 0.12m in suspension 3 / L rate into CO 2 Gas, until the pH value of the solution is 7.3 to 7.8, stop the ventilation, and get heavy magnesium water Mg (HCO 3 ) 2 solution.

[0080] (4) the above-mentioned gained heavy magnesium water Mg (HCO 3 ) 2 The solution was stirred and reacted at 50°C at a rate of 300r / min for 1.5h, the stirring was stopped, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com