Treating method for reverse osmosis (RO) concentrated water

A reverse osmosis concentrated water and treatment method technology, which is applied in the field of reverse osmosis concentrated water treatment, can solve problems such as limited processing capacity and limited application range, and achieve the effects of solving difficult removal problems, improving treatment effect, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

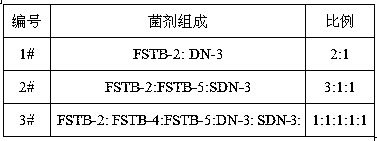

[0024] The preparation method of embodiment 1 microbial bacterial agent

[0025] (1) Inoculate Paracoccus FSTB-2, Microbacterium Kitami FSTB-4 and Pseudomonas stutzeri FSTB-5 on FSTB solid medium for activation respectively; denitrifying Paracoccus DN-3 and A Bacteria SDN-3 were respectively inoculated on the corresponding solid medium for activation; spread evenly and placed in a constant temperature incubator at 35°C for activation.

[0026] (2) Use the inoculation loop to inoculate the colonies of Paracoccus FSTB-2, Kitamibacterium FSTB-4 and Pseudomonas stutzeri FSTB-5 on the plate into the corresponding FSTB liquid medium respectively, and use the inoculation loop to Take the colonies of Paracoccus denitrificans DN-3 and Methylobacterium SDN-3 on the plate and inoculate them in the corresponding liquid medium respectively, and culture them with shaking at 30°C and 150rpm for 48 hours to the logarithmic growth phase to obtain liquid bacteria agent seed liquid.

[0027] (...

Embodiment 2

[0034] The RO concentrated water produced by a refinery company has a COD of 100mg / L, a total nitrogen of 80mg / L, a salt concentration of 5000mg / L, and a B / C ratio of less than 0.1. Treated by the method of the present invention, the sewage first enters the ozone catalytic oxidation unit, and the catalyst prepared by the embodiment 1 in CN201310621081.2 is used to load the reactor, the loading amount is 1 / 3 of the reactor volume, and the test conditions are: volumetric space velocity 0.5 h -1 ;O 3 Concentration 50g / m 3 , O 3 The dosage is 2000mg / L. The B / C ratio of the effluent from the ozone catalytic oxidation unit was increased to 0.7. Sewage after ozone oxidation enters the buffer tank to remove the remaining ozone. Then, according to the designed water volume, it enters the bio-enhanced treatment unit and is treated by three sets of alternately operating SBR processes. The operating time of a single set of SBR is 8 hours, aeration is 2 hours, stirring is 1 hour, circ...

Embodiment 3

[0036] The RO concentrated water produced by a refinery company has a COD of 300mg / L, a total nitrogen of 150mg / L, a salt concentration of 5000mg / L, and a B / C ratio of less than 0.1. Treated by the method of the present invention, the sewage first enters the ozone catalytic oxidation unit, and the catalyst prepared by the embodiment 1 in CN201310621081.2 is used to load the reactor, the loading amount is 1 / 3 of the reactor volume, and the test conditions are: volumetric space velocity 0.5 h -1 ;O 3 Concentration 70g / m 3 , O 3 The dosage is 3000mg / L. The effluent B / C of the ozone catalytic oxidation unit was increased to 0.8. Sewage after ozone oxidation enters the buffer tank to remove the remaining ozone. Then, according to the designed water volume, it enters the bio-enhanced treatment unit, and is treated by two sets of alternately operating SBR processes. The operating time of a single set of SBR is 12 hours, aeration is 3 hours, stirring is 2 hours, circulation is tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com