Three-dimensional covalent organic framework materials and synthesis methods based on tetrathiafulvalene units

A covalent organic framework, tetrathiafulvalene technology, applied in separation methods, organic chemistry, chemical instruments and methods, etc., to achieve the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 5 mg (0.01 mmol) of tetrahedral configuration tetrakis (4-anilino) adamantane (TAPA) and 6.2 mg (0.01 mmol) tetrakis (p-phenylaldehyde) tetrathiafulvalene (TTF-Ph-CHO) were added Add 1mL of o-dichlorobenzene to the ampoule, mix evenly by ultrasonic, then add 0.1mL (6mol / L) acetic acid aqueous solution, place the ampoule in liquid nitrogen for freezing, vacuumize and seal the tube with flame, after sealing the tube Place in an oven and heat up to 140°C for 5 days. After the reaction, the obtained solid was transferred to a centrifuge tube, washed with N,N-dimethylformamide and tetrahydrofuran for 5 times, heated and vacuum-dried at 80°C for 12 hours, and 7 mg of dark red solid powder COF was obtained. -TTF-Ad, the yield is 70%, and the reaction formula is shown in the following formula.

[0033]

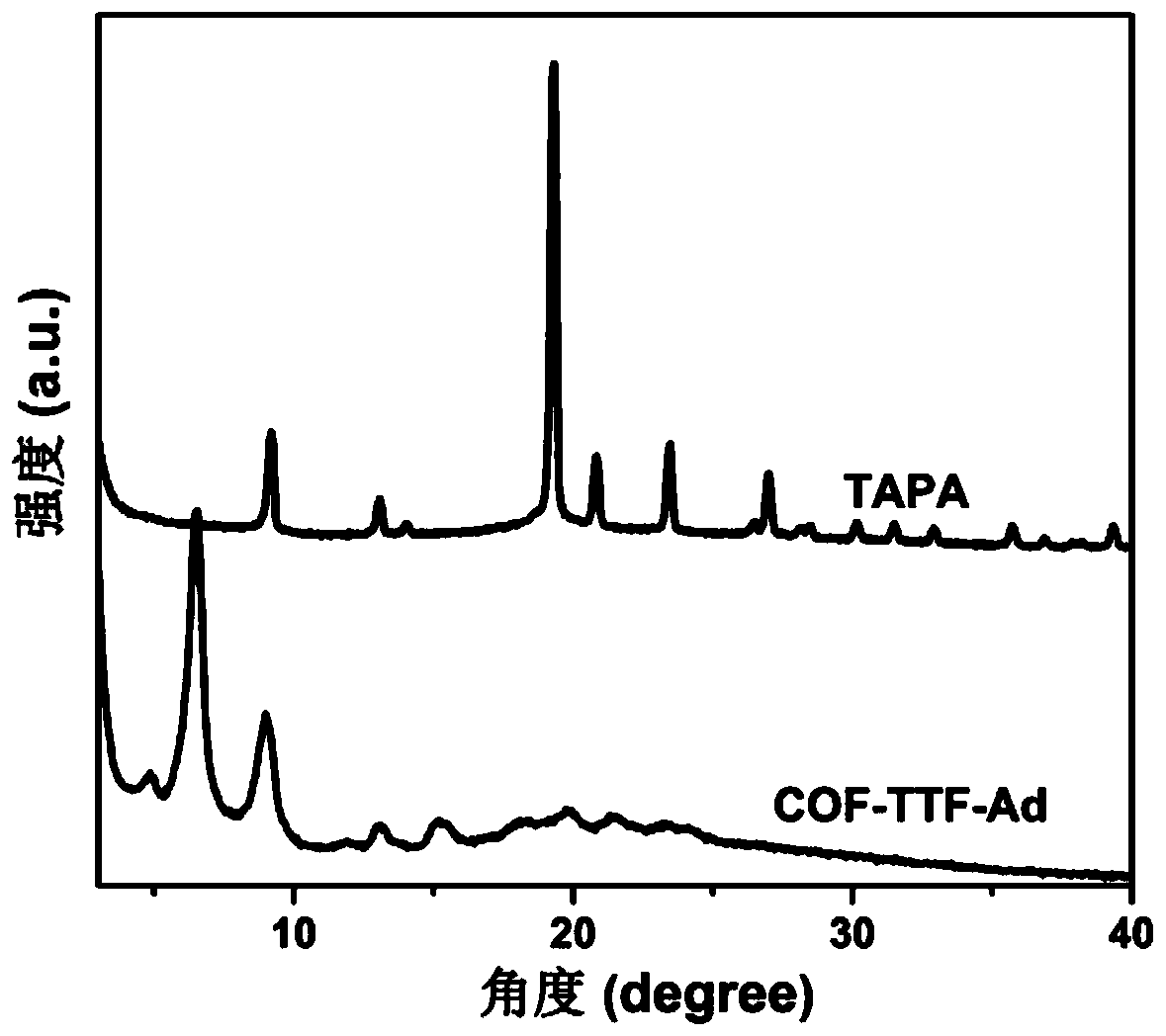

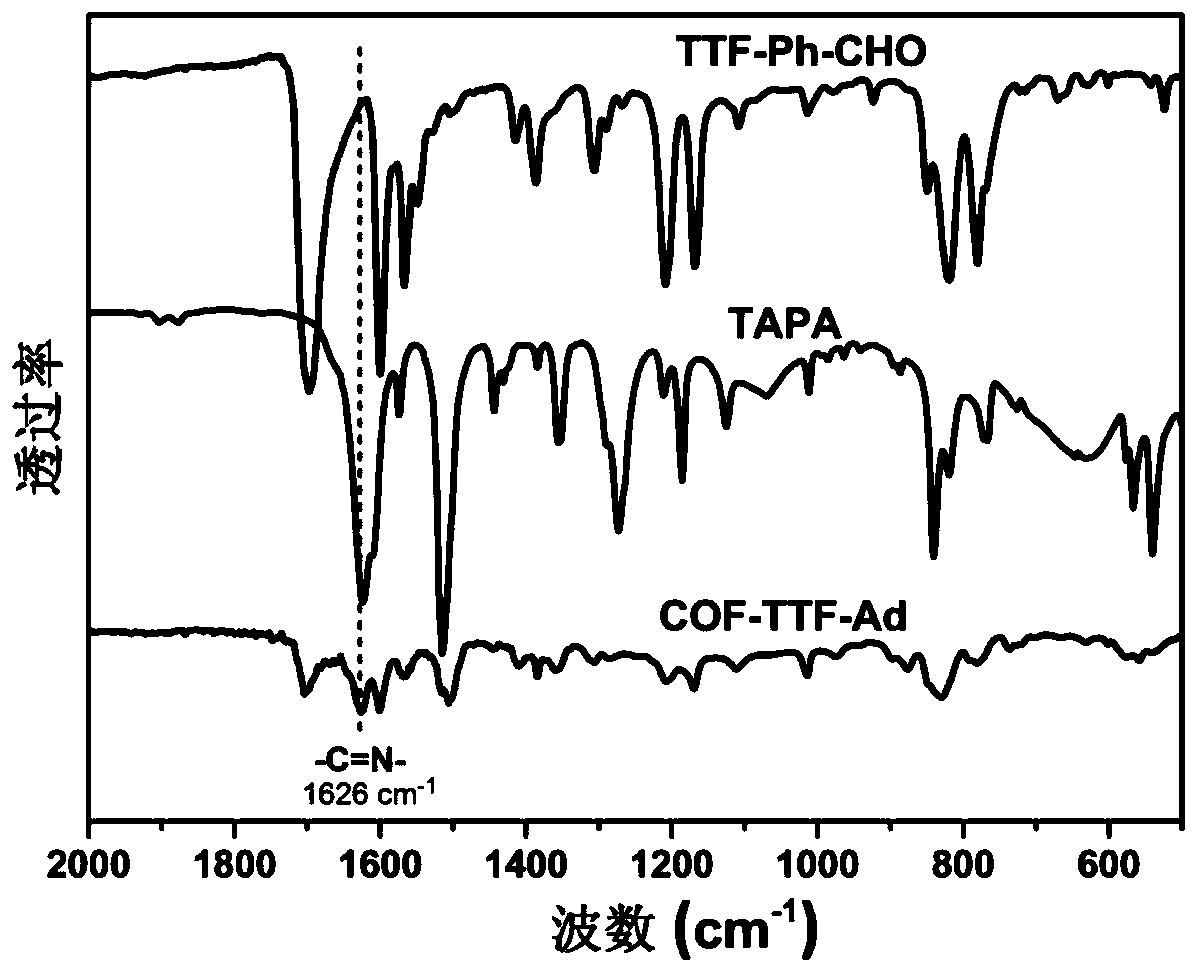

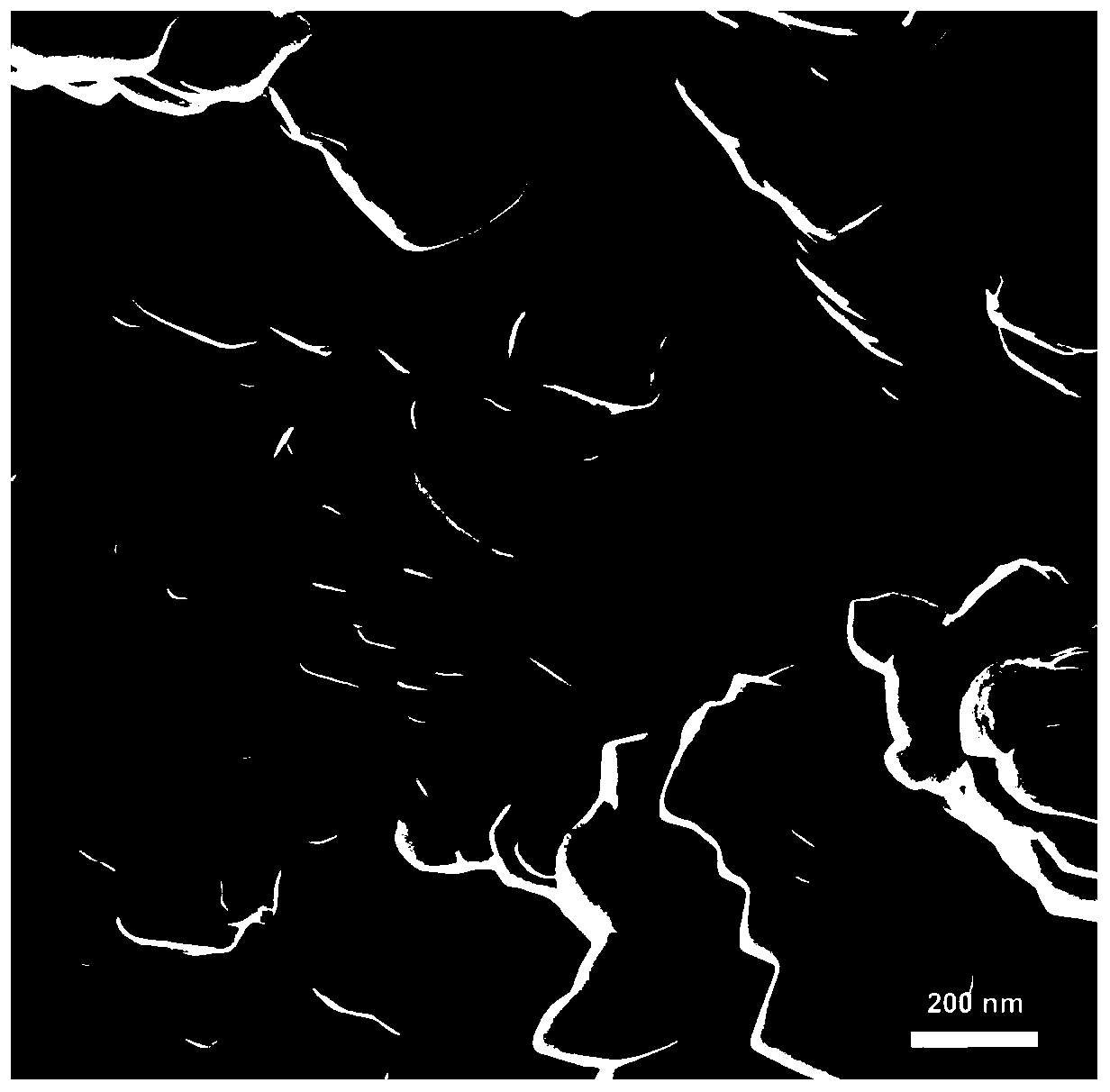

[0034] Such as figure 1 As shown, by comparing the powder X-ray diffraction spectra of the COF-TTF-Ad synthesized in the present invention and the raw material monomer TAP...

Embodiment 2

[0042]5 mg (0.01 mmol) of tetrahedral configuration tetrakis (4-anilino) adamantane (TAPA) and 6.2 mg (0.01 mmol) tetrakis (p-phenylaldehyde) tetrathiafulvalene (TTF-Ph-CHO) were added Add 1mL of o-dichlorobenzene to the ampoule, mix well by ultrasonic, then add 0.1mL (3mol / L) acetic acid aqueous solution, place the ampoule in liquid nitrogen for freezing, vacuumize and seal the tube with flame, after sealing the tube Place in an oven and heat up to 140°C for 5 days. After the reaction, the obtained solid was transferred to a centrifuge tube, washed with N,N-dimethylformamide and tetrahydrofuran for 5 times, heated and vacuum-dried at 80°C for 12 hours to obtain 5 mg of dark red solid powder COF -TTF-Ad, yield 55%. Through the powder X-ray diffraction test, it can be confirmed that a new three-dimensional covalent organic framework material has been successfully synthesized, and its performance test results are as follows: specific surface area: 1245m 2 / g; at a pressure of ...

Embodiment 3

[0044] 5 mg (0.01 mmol) of tetrahedral configuration tetrakis (4-anilino) adamantane (TAPA) and 6.2 mg (0.01 mmol) tetrakis (p-phenylaldehyde) tetrathiafulvalene (TTF-Ph-CHO) were added To the ampoule bottle, add 0.8mL o-dichlorobenzene and 0.2mL mesitylene, ultrasonically mix evenly, then add 0.1mL (6mol / L) acetic acid aqueous solution, place the ampoule bottle in liquid nitrogen for freezing, vacuumize and Seal the tube with flame, place the tube in an oven after sealing, and heat up to 140°C for 5 days. After the reaction, the obtained solid was transferred to a centrifuge tube, washed with N,N-dimethylformamide and tetrahydrofuran for 5 times, heated and vacuum-dried at 80°C for 12 hours to obtain 6.5 mg of dark red solid powder COF-TTF-Ad, yield 65%. Through the powder X-ray diffraction test, it can be confirmed that a new three-dimensional covalent organic framework material has been successfully synthesized, and its performance test results are as follows: specific sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com