SiC-based GaN_HEMT back technology based on graphical slide

A backside process and patterning technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of removal of etching by-products that affect the etching rate, affect the performance of front-side devices, and reduce the yield rate, etc., to achieve It is beneficial to device performance and yield, improves thermal conductivity, and reduces etching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

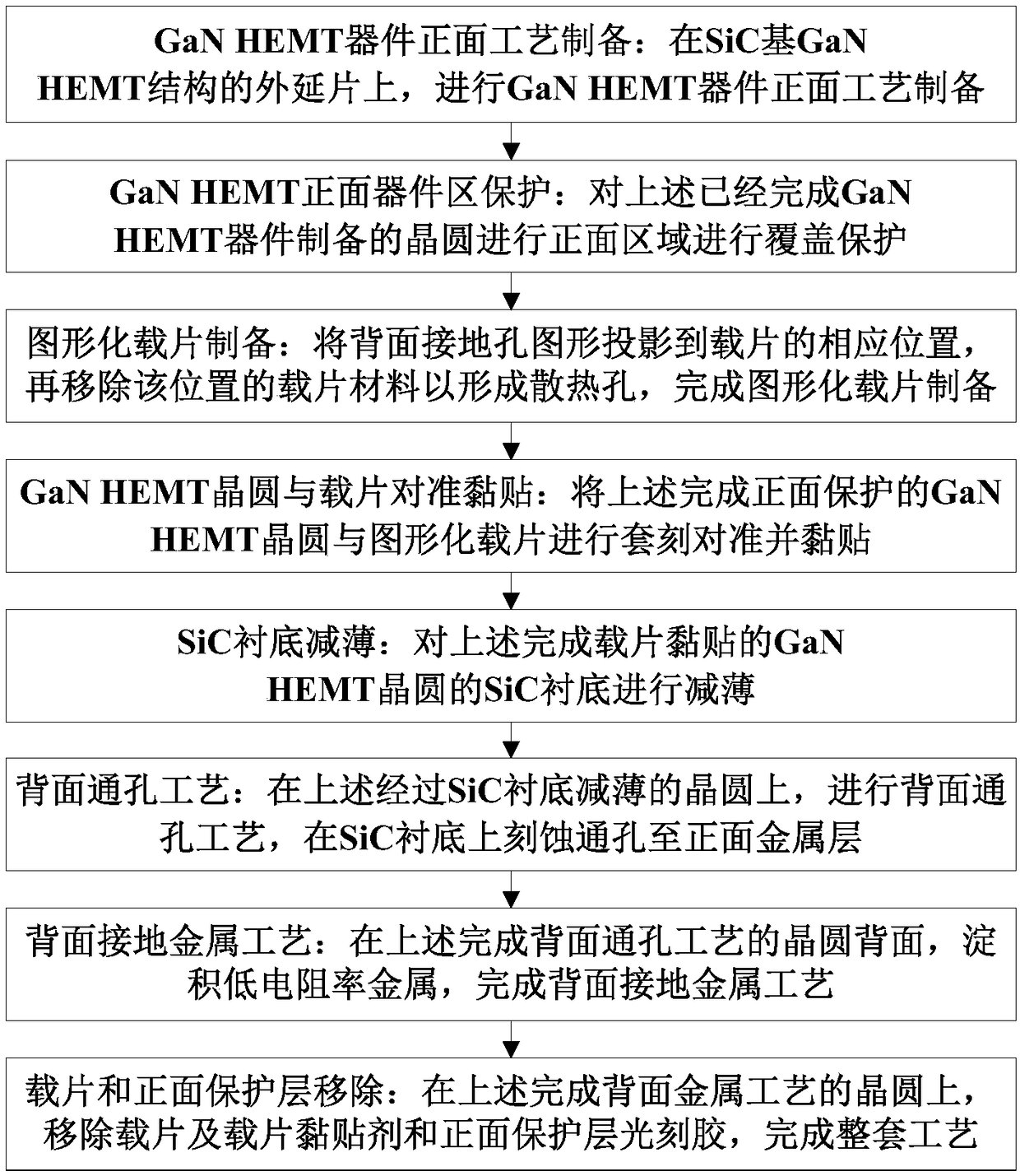

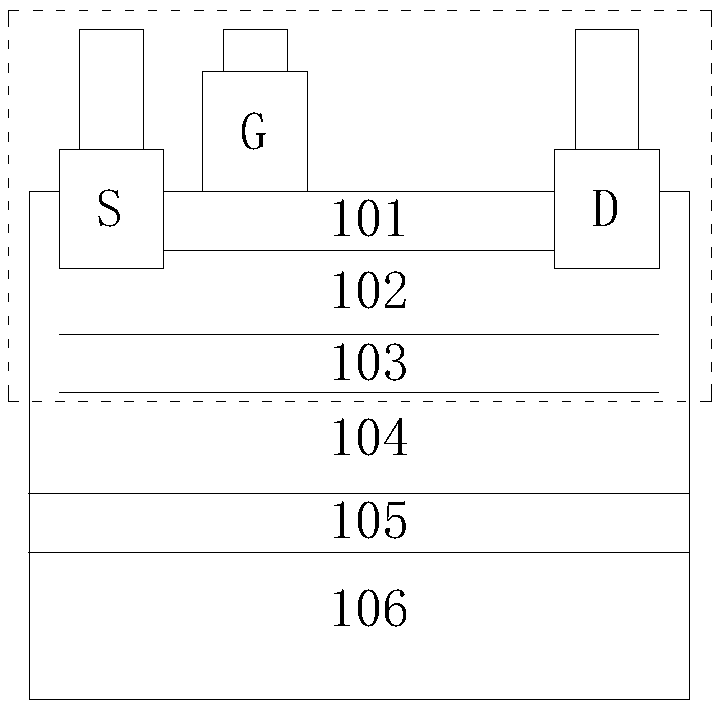

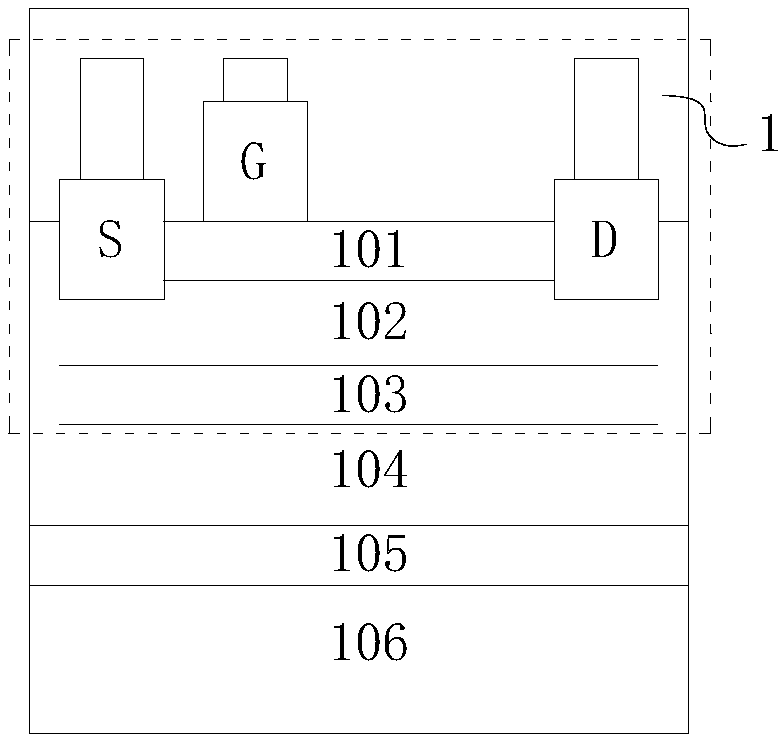

[0034] Such as Figure 1-9 As shown, an embodiment of a SiC-based GaN_HEMT backside process based on a patterned carrier of the present invention and a corresponding structural schematic diagram, the specific steps are as follows:

[0035] Step 1, front-side process preparation of GaN HEMT devices: On the epitaxial wafer of SiC-based GaN HEMT structure, the front-side process preparation of GaN HEMT devices is carried out.

[0036] On the epitaxial wafer of SiC-based GaN HEMT structure, the GaN HEMT device front-side process preparation is carried out. The preparation steps include but are not limited to, active area isolation, source and drain metal preparation, gate metal preparation, capacitor and inductor preparation, and electrode addition. Thick, metal interconnection and other related processes.

[0037] In one embodiment, on the epitaxial wafer of SiC-based GaN HEMT structure, device active region isolation is formed by fluorine ion implantation; Anneal in nitrogen a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com