Horseradish microcapsule suspending agent and preparation method thereof

A microcapsule suspension, horseradish microtechnology, applied in the field of horseradish microcapsule suspension and its preparation, can solve the problem of high application cost, achieve short reaction time, improve stability, and reduce the number of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

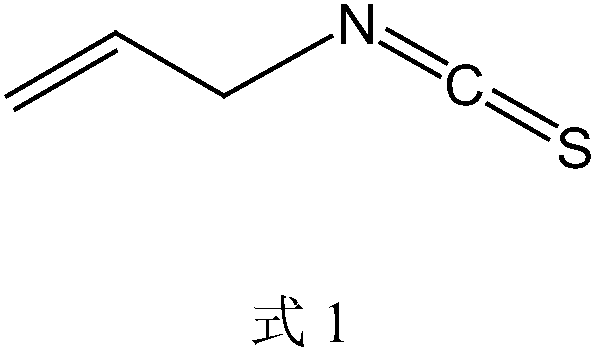

[0037] Embodiment 1: horseradish microcapsule suspension

[0038] 1. Preparation method

[0039]1) Oil phase preparation: add 0.15g emulsifier (0.10g castor oil polyoxyethylene ether + 0.05g calcium dodecylbenzenesulfonate) to 2.00g horseradish, mix well, then add 0.10g stabilizer Epichlorohydrin and 0.20 g of oil-phase monomer toluene-2,4-diisocyanate were uniformly mixed to obtain an oil-phase mixed liquid.

[0040] 2) Water phase preparation: 1.00 g of thickener hydroxyethyl cellulose was dissolved in 99.00 g of deionized water to obtain a 1.00% hydroxyethyl cellulose solution.

[0041] 3) Mixing: Mix 2.45 g of the oil phase mixture in step 1) and 16.55 g of the thickener hydroxyethyl cellulose solution in step 2), stir evenly, and emulsify at 20°C at 3000 rpm for 0.5 min at high speed, A microsuspension of the O / W system was obtained.

[0042] 4) Polymerization: Stir the microsuspension obtained in step 3) at a slow speed, slowly add 1.00 g of 1% ethylenediamine aqueous...

Embodiment 2

[0045] Embodiment 2: horseradish microcapsule suspension

[0046] 1. Preparation method

[0047] 1) Oil phase preparation: add 0.15g emulsifier (0.10g castor oil polyoxyethylene ether + 0.05g calcium dodecylbenzenesulfonate) to 2.00g horseradish, mix well, then add 0.20g stabilizer Epichlorohydrin and 0.20 g of oil-phase monomer toluene-2,4-diisocyanate were uniformly mixed to obtain an oil-phase mixed liquid.

[0048] 2) Water phase preparation: 1.00 g of thickener hydroxyethyl cellulose was dissolved in 99.00 g of deionized water to obtain a 1.00% hydroxyethyl cellulose solution.

[0049] 3) Mixing: Mix 2.45 g of the oil phase mixture in step 1) and 16.55 g of the thickener hydroxyethyl cellulose solution in step 2), stir evenly, and emulsify at 20°C at 3000 rpm for 0.5 min at high speed, A microsuspension of the O / W system was obtained.

[0050] 4) Polymerization: Stir the micro-suspension obtained in step 3) at a slow speed, slowly add 1.00 g of 0.5% ethylenediamine aqu...

Embodiment 3

[0053] Embodiment 3: horseradish microcapsule suspension

[0054] 1. Preparation method

[0055] 1) Oil phase preparation: add 0.15g emulsifier (0.10g castor oil polyoxyethylene ether + 0.05g calcium dodecylbenzenesulfonate) to 2.00g horseradish, mix well, then add 0.10g stabilizer Epichlorohydrin and 0.20 g of oil-phase monomer toluene-2,4-diisocyanate were uniformly mixed to obtain an oil-phase mixed liquid.

[0056] 2) Water phase preparation: 0.50 g of thickener xanthan gum was dissolved in 99.50 g of deionized water to obtain a 0.50% xanthan gum solution.

[0057] 3) Mixing: Mix 2.45 g of the oil phase mixture in step 1) and 16.55 g of the thickener xanthan gum solution in step 2), stir evenly, and emulsify at 3000 rpm at 20°C for 0.5 min at high speed to obtain O / W system microsuspension.

[0058] 4) Polymerization: Stir the microsuspension obtained in step 3) at a slow speed, slowly add 1.00 g of 1% ethylenediamine aqueous solution dropwise, after 5 minutes of compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com