Preparation of a polytetrafluoroethylene hollow fiber membrane, membrane, membrane contactor and application

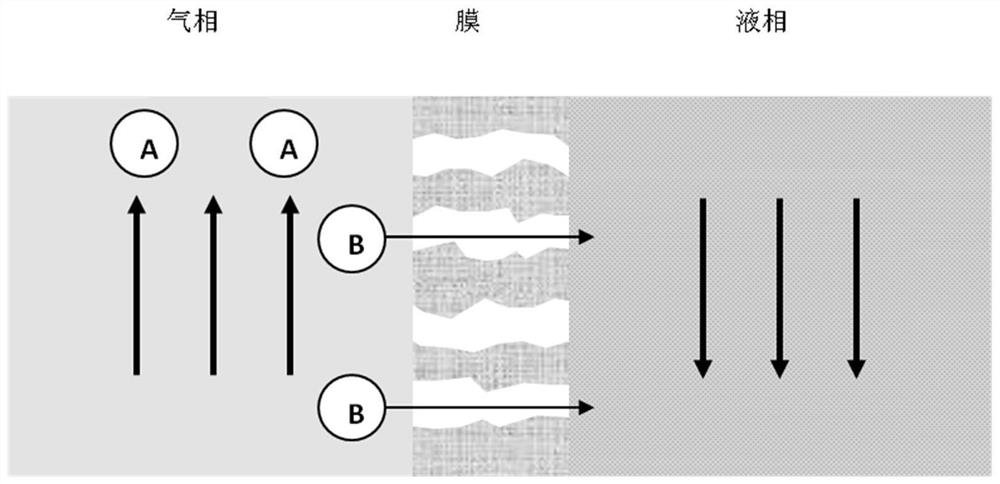

A polytetrafluoroethylene and fiber membrane technology is used in the preparation of polytetrafluoroethylene hollow fiber membranes, as well as in the fields of membrane and membrane contactors and applications, to achieve the effects of improving dispersibility, improving affinity, and obvious pore-forming effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

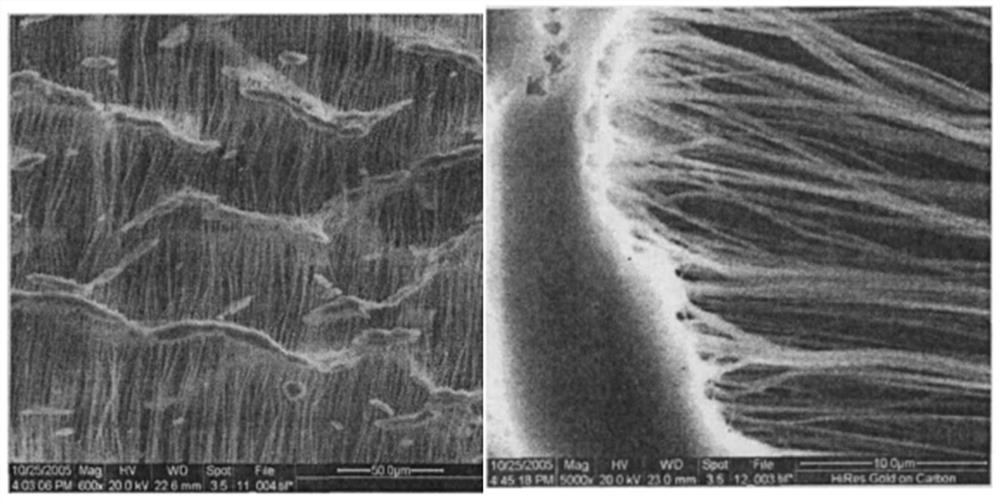

[0021] Mix PTFE resin, isoparaffin oil, and fumaric acid evenly at a mass ratio of 100:35:40. After the mixture is sealed and allowed to stand at 35°C for 48 hours, it is pre-pressed into a PTFE body by a pre-pressing machine. After extrusion, a PTFE primary fiber membrane is formed. The extrusion temperature is 95°C. After removing the lubricating aid at 300°C, it is sintered at 360°C for 180s to obtain a polytetrafluoroethylene hollow fiber membrane. The obtained hollow fiber membrane has an inner and outer diameter of 0.2-0.8 mm, a porosity of 62%, an average pore diameter of 0.17 μm, and a static water contact angle of 125°.

[0022] The membrane contactor assembly is filled with the above-mentioned membrane filaments, the filling rate is 50%, and the two ends of the membrane contactor are encapsulated with epoxy resin. With 15% CO 2 / N 2 The mixed gas is the raw material gas, the aqueous solution of diethanolamine with a mass fraction of 30% is used as the absorbent, an...

Embodiment 2

[0024] Mix PTFE resin, isoparaffin oil, cetyltrimethylammonium bromide-modified fumaric acid at a mass ratio of 100:25:15, and keep the mixture at 22°C for 96 hours, then use a pre- The press pre-presses it into a PTFE green body, and forms a PTFE primary fiber film after high-pressure extrusion. The extrusion temperature is 45°C. After removing the lubricating aid at 340°C, it is sintered at 390°C for 60s to obtain a polyester fiber. Tetrafluoroethylene hollow fiber membrane. The obtained hollow fiber membrane has an inner and outer diameter of 1-1.8 mm, a porosity of 35%, an average pore diameter of 0.08 μm, and a static water contact angle of 110°.

[0025] The membrane contactor assembly is filled with the above-mentioned membrane filaments, the filling rate is 60%, and the two ends of the membrane contactor are encapsulated with epoxy resin. With 15% CO 2 / N 2 The mixed gas is the raw material gas, the aqueous solution of diethanolamine with a mass fraction of 30% is u...

Embodiment 3

[0027]Mix PTFE resin, isoparaffin oil, and naphthalene evenly at a mass ratio of 100:30:30. After the mixture is sealed and allowed to stand at 50°C for 36 hours, it is pre-pressed into a PTFE body with a pre-pressing machine and extruded under high pressure. After that, PTFE primary fiber membrane is formed, and the extrusion temperature is 80°C. After removing the lubricating aid at 330°C, it is sintered at 340°C for 450s to obtain a polytetrafluoroethylene hollow fiber membrane. The obtained hollow fiber membrane has an inner and outer diameter of 0.8-1.5 mm, a porosity of 55%, an average pore diameter of 0.45 μm, and a static water contact angle of 115°.

[0028] The membrane contactor assembly is filled with the above-mentioned membrane filaments, the filling rate is 50%, and the two ends of the membrane contactor are encapsulated with epoxy resin. With 15% CO 2 / N 2 The mixed gas is the raw material gas, the aqueous solution of diethanolamine with a mass fraction of 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com