Cobalt titanate doped titanium nitride photocatalyst for hydrogen production and preparation method

A technology of titanium nitride and cobalt titanate, which is applied in the field of cobalt titanate doped titanium nitride photocatalyst and preparation, can solve the problems of small specific surface area, weak visible light absorption ability, complicated synthesis process, etc., and achieves the improvement of hydrogen production efficiency , good photoresponsivity, and the effect of improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

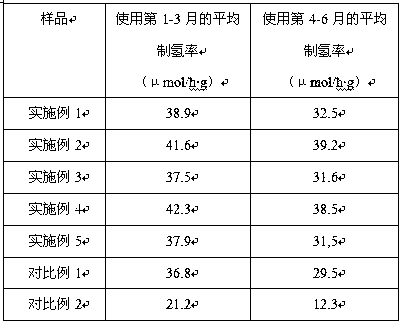

Examples

Embodiment 1

[0030] Cobalt titanate-doped titanium nitride composite photocatalyst preparation method for hydrogen production, in a closed container with a nitrogen concentration of 80%, titanium dioxide nanotubes and metal magnesium particles are placed in a reactor at a mass ratio of 2:1 Among them, the particle size of nanoparticles composed of titanium dioxide nanotubes is 30nm, and the particle size of metal magnesium particles is 0.2mm, and then react at a high temperature of 900°C to obtain titanium nitride, and the prepared titanium nitride is added to the deionized A suspension is formed in a solution composed of hydrated ethanol. The mass fraction of titanium nitride in the suspension is 35%, and the mass fraction of ethanol is 50%. Add cobalt titanate to the liquid so that the mass fraction of cobalt titanate in the mixed suspension is 6%. The mixed suspension is stirred and reacted, centrifuged, permeated and filtered, finally dried at 600°C for 5 hours, and laser sintered to ob...

Embodiment 2

[0032]Cobalt titanate-doped titanium nitride composite photocatalyst preparation method for hydrogen production, in a closed container with a nitrogen concentration of 65%, titanium dioxide nanotubes and metal magnesium particles are placed in a reactor at a mass ratio of 1:1 Among them, the particle size of nanoparticles composed of titanium dioxide nanotubes is 20nm, and the particle size of metal magnesium particles is 0.1mm, and then react at a high temperature of 800°C to obtain titanium nitride, and the prepared titanium nitride is added to the deionized hydration A suspension is formed in a solution composed of ethanol. The mass fraction of titanium nitride in the suspension is 30%, and the mass fraction of ethanol is 40%. The suspension is incubated for 3 hours at a temperature of 80°C, and finally added to the suspension Cobalt titanate was added to the mixed suspension so that the mass fraction of cobalt titanate in the mixed suspension was 5%, the mixed suspension wa...

Embodiment 3

[0034] Preparation method of cobalt titanate-doped titanium nitride composite photocatalyst for hydrogen production. In a closed container with a nitrogen concentration of 70%, titanium dioxide nanotubes and metal magnesium particles are placed in a reactor at a mass ratio of 1:1 Among them, the particle size of nanoparticles composed of titanium dioxide nanotubes is 25nm, and the particle size of metal magnesium particles is 0.2mm, and then react at a high temperature of 1000°C to obtain titanium nitride, and the prepared titanium nitride is added to the deionized hydration A suspension is formed in a solution composed of ethanol. The mass fraction of titanium nitride in the suspension is 35%, and the mass fraction of ethanol is 50%. The suspension is incubated for 4 hours at a temperature of 85°C, so that in the mixed solution The mass fraction of cobalt titanate was 6%. The mixed suspension was stirred and reacted, centrifuged, permeated and filtered, and finally dried at 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com