Aluminum ion-doped mesoporous titanium dioxide lithium battery anode material and preparation method thereof

A technology of mesoporous titanium dioxide and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor conductivity of negative electrode materials, poor conductivity of titanium dioxide negative electrodes, etc., and achieve improved lithium storage specific capacity and cycle performance, Effect of high lithium storage specific capacity and electrochemical performance, small nanoparticle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Add 4.5 grams of tetrabutyl titanate and 0.2 grams of anhydrous aluminum chloride into 15 milliliters of ethanol, then slowly add 150 milliliters of deionized water and 150 milliliters of 35% hydrochloric acid, and stir evenly to obtain a first reaction solution. 0.8 g of P123 was added into 15 ml of ethanol, and stirred evenly to obtain a second reaction solution. Mix the above first reaction solution with the second reaction solution and stir at room temperature to obtain a uniform light yellow sol. Then the sol was poured into a petri dish and aged for 24 hours under heating conditions to obtain a light yellow transparent xerogel. Finally, the dry gel was taken out, put into a muffle furnace and heat-treated at 400° C. in air for 4 hours at a heating rate of 10° C. / min. Finally, a mesoporous titania material doped with aluminum ions is obtained;

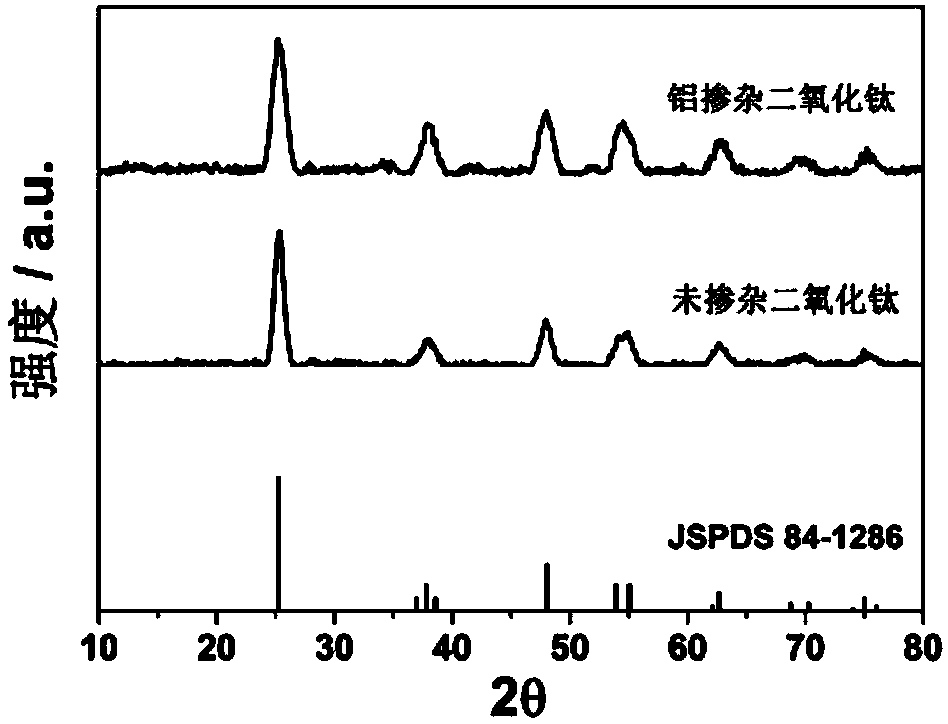

[0041] Carry out XRD test to the mesoporous titania material that obtains aluminum ion doping, test result is as follows...

Embodiment 2

[0047] 4.5 grams of tetrabutyl titanate and 0.1 grams of anhydrous aluminum chloride were added to 15 milliliters of ethanol, and then 100 milliliters of deionized water and 50 milliliters of 35% hydrochloric acid were added slowly, and the first reaction solution was obtained after uniform stirring. 1.6 g of P123 was added into 30 ml of ethanol, and stirred evenly to obtain a second reaction solution. Mix the above first reaction solution with the second reaction solution and stir at room temperature to obtain a uniform light yellow sol. Then the sol was poured into a petri dish and aged under heating for 18 hours to obtain a light yellow transparent xerogel. Finally, the dry gel was taken out and put into a muffle furnace for heat treatment at 500° C. in air for 4 hours at a heating rate of 10° C. / min. Finally, the aluminum ion-doped mesoporous titania material is obtained.

Embodiment 3

[0049] Add 3.7 g of tetrabutyl titanate and 0.4 g of anhydrous aluminum chloride into 15 ml of ethanol, then slowly add 150 ml of deionized water and 150 ml of 35% hydrochloric acid, and stir evenly to obtain a first reaction solution. 0.8 g of P123 was added into 15 ml of ethanol, and stirred evenly to obtain a second reaction solution. Mix the above first reaction solution with the second reaction solution and stir at room temperature to obtain a uniform light yellow sol. Then the sol was poured into a petri dish and aged under heating for 20 hours to obtain a light yellow transparent xerogel. Finally, the dry gel was taken out and put into a muffle furnace for heat treatment at 450° C. in air for 4 hours at a heating rate of 5° C. / min. Finally, the aluminum ion-doped mesoporous titania material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com