Preparation method of ferrothiofluorine or chloride modified three-dimensinoal graphene composite material

A composite material, chloride technology, applied in graphene, iron oxide/iron hydroxide, iron oxide and other directions, to achieve the effect of simple method, short production cycle, rich mesoporous microporous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

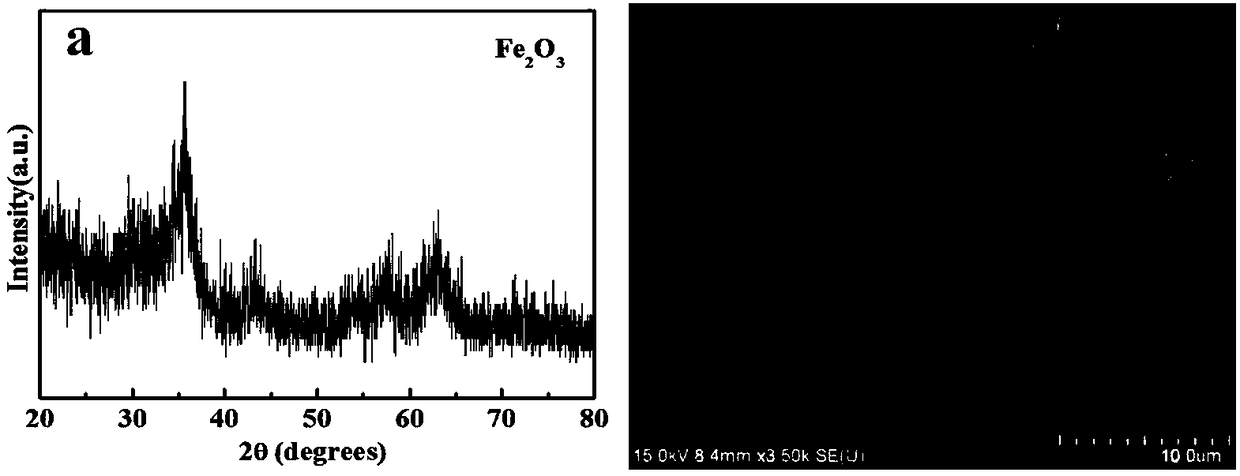

[0025] Weigh polyvinylpyrrolidone K30 powder and Fe(NO 3 ) 3 9H 2 The powder with O mass fraction of 1:1 was dissolved in deionized water and stirred ultrasonically for 10 min, and the product after the mixed solution was completely dried in a drying oven was ground into a powder, and the powder was transferred to a tubular sintering furnace under N 2 The three-dimensional graphene composite material decorated with iron carbide nanoparticles was obtained by keeping it at 700°C for 2 hours in the atmosphere. Take 0.12g of the three-dimensional graphene composite material decorated with iron carbide nanoparticles and keep it at 300°C in the air atmosphere of the tubular sintering furnace for 1.5h to obtain Three-dimensional graphene composites decorated with iron oxide nanoparticles.

Embodiment 2

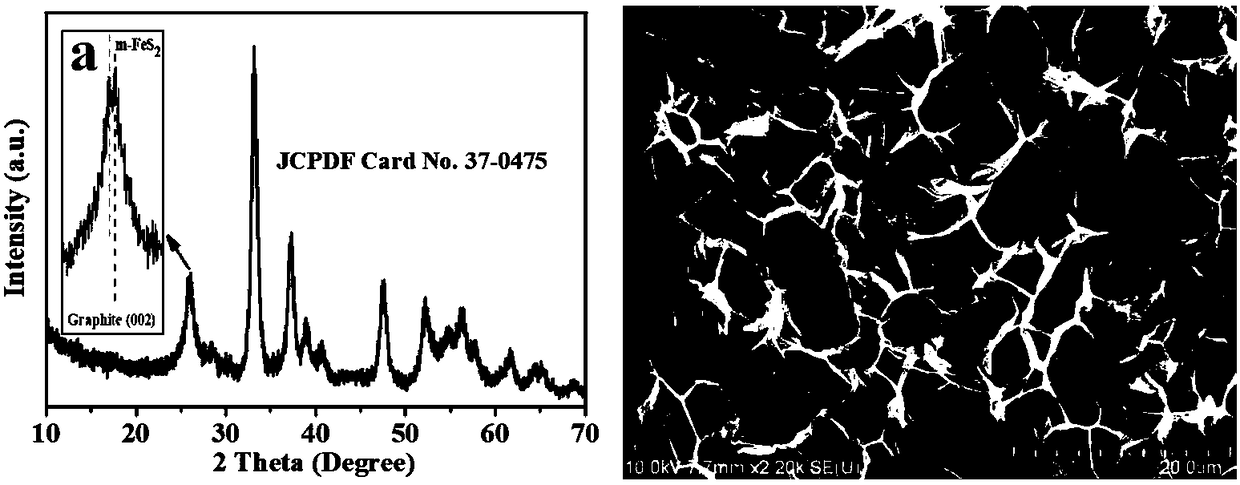

[0027] Weigh polyvinylpyrrolidone K30 powder and Fe(NO 3 ) 3 9H 2 The powder whose mass fraction is 1:1.5 was dissolved in deionized water and stirred ultrasonically for 15 min, and the product after the mixed solution was completely dried in a drying oven was ground into a powder, and the powder was transferred to a tubular sintering furnace under N 2 Keep warm at 700°C for 2 hours in the atmosphere to obtain iron carbide nanoparticles modified three-dimensional graphene composites. Take 0.2g iron carbide nanoparticles modified three-dimensional graphene composites and mix them with 0.4g sublimated sulfur, and heat them in a tubular sintering furnace with nitrogen atmosphere at 300°C. Insulated for 2 hours under the same conditions to obtain a three-dimensional graphene composite material decorated with iron sulfide nanoparticles.

Embodiment 3

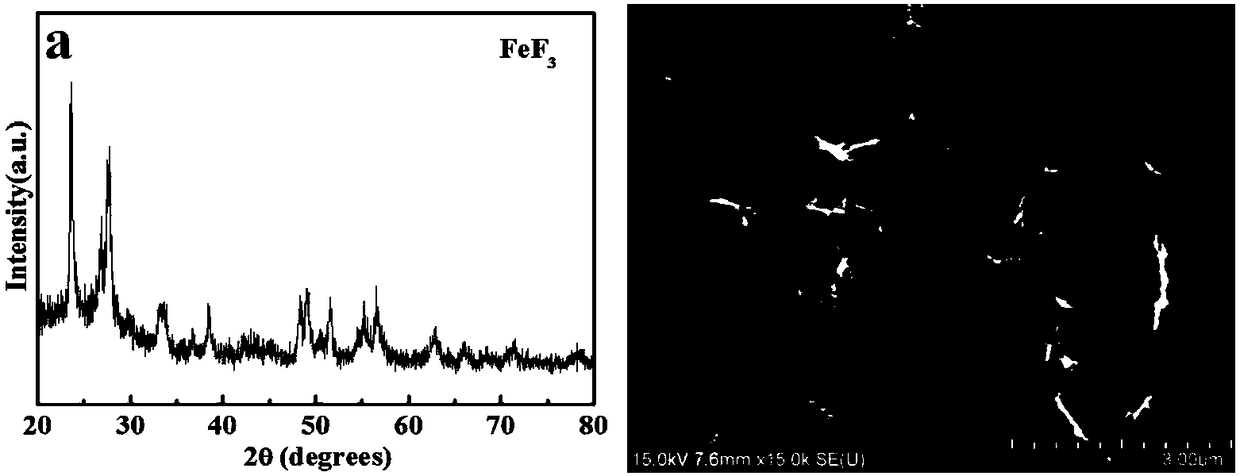

[0029] Weigh polyvinylpyrrolidone K30 powder and Fe(NO 3 ) 3 9H 2 The powder whose mass fraction is 1:1.2 was dissolved in deionized water and stirred ultrasonically for 20min, and the product after the mixed solution was completely dried in a drying oven was ground into a powder, and the powder was transferred to a tubular sintering furnace under N 2 In the atmosphere, keep warm at 700°C for 2 hours to obtain iron carbide nanoparticles modified three-dimensional graphene composite materials. Take 0.21g of iron carbide nanoparticles modified three-dimensional graphene composite materials and mix them with 0.64g of ammonium fluoride. The temperature was kept at ℃ for 2 hours to obtain a three-dimensional graphene composite material decorated with ferric fluoride nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com