Polyvinyl chloride cable material with excellent flame resistance and preparation method thereof

A polyvinyl chloride cable, flame retardant technology, applied in the field of power cables, can solve the problems of low oxygen index, affecting the application range of polyethylene cable materials, flammability and other problems, to improve safety performance, good mechanical performance, and broad market foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

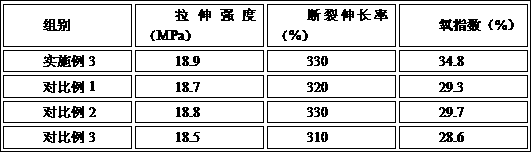

Examples

Embodiment 1

[0026] A polyvinyl chloride cable material with excellent flame retardancy, made of the following raw materials in parts by weight: 110 parts of polyvinyl chloride resin, 4 parts of acetylene carbon black, 1 part of anti-aging agent, 5 parts of flame retardant, 0.7 parts of kaempferol 2 parts, 2 parts of triaryl phosphate, 3 parts of chlorinated paraffin, 2 parts of epoxidized soybean oil, 1 part of barium stearate, 1 part of toner, 6 parts of rare earth stabilizer, 11 parts of calcium carbonate, diphthalate 17 parts of octyl esters.

[0027] Wherein, the anti-aging agent is anti-aging agent CPPD; the flame retardant is composed of antimony trioxide and zinc borate in a weight ratio of 2:1.

[0028] In this embodiment, the preparation method of the polyvinyl chloride cable material with excellent flame retardant properties, the steps are as follows:

[0029] 1) Weigh the triaryl phosphate and kaempferol, add ethanol to the triaryl phosphate, stir and mix at 100rpm for 10min, ...

Embodiment 2

[0037] A polyvinyl chloride cable material with excellent flame retardancy, made of the following raw materials in parts by weight: 111 parts of polyvinyl chloride resin, 5 parts of acetylene carbon black, 1.2 parts of anti-aging agent, 8 parts of flame retardant, and 0.9 parts of kaempferol Parts, 4 parts of triaryl phosphate, 4 parts of chlorinated paraffin, 3 parts of epoxidized soybean oil, 1.7 parts of barium stearate, 2.5 parts of color powder, 7 parts of rare earth stabilizer, 15 parts of calcium carbonate, diphthalic acid 18 parts of octyl esters.

[0038] Wherein, the anti-aging agent is anti-aging agent CPPD; the flame retardant is composed of antimony trioxide and zinc borate in a weight ratio of 2:1.

[0039] In this embodiment, the preparation method of the polyvinyl chloride cable material with excellent flame retardant properties, the steps are as follows:

[0040] 1) Weigh the triaryl phosphate and kaempferol, add ethanol to the triaryl phosphate, stir and mix...

Embodiment 3

[0048] A polyvinyl chloride cable material with excellent flame retardancy, made of the following raw materials in parts by weight: 113 parts of polyvinyl chloride resin, 6 parts of acetylene carbon black, 1.5 parts of anti-aging agent, 7 parts of flame retardant, and 0.9 parts of kaempferol 3.5 parts of triaryl phosphate, 4.5 parts of chlorinated paraffin, 3.5 parts of epoxidized soybean oil, 1.4 parts of barium stearate, 2 parts of toner, 8 parts of rare earth stabilizer, 14 parts of calcium carbonate, diphthalate 19 parts of octyl esters.

[0049] Wherein, the anti-aging agent is anti-aging agent CPPD; the flame retardant is composed of antimony trioxide and zinc borate in a weight ratio of 2:1.

[0050] In this embodiment, the preparation method of the polyvinyl chloride cable material with excellent flame retardant properties, the steps are as follows:

[0051] 1) Weigh the triaryl phosphate and kaempferol, add ethanol to the triaryl phosphate, stir and mix at 150rpm for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com