Preparation method of drier for water-based alkyd resin

A technology of water-based alkyd resin and drier, which is applied in the direction of polyester coatings and coatings. It can solve the problems of deep color, high viscosity, and heavy odor of drier, and achieve short surface drying time, good whiteness, Promotes the drying effect of the bottom layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

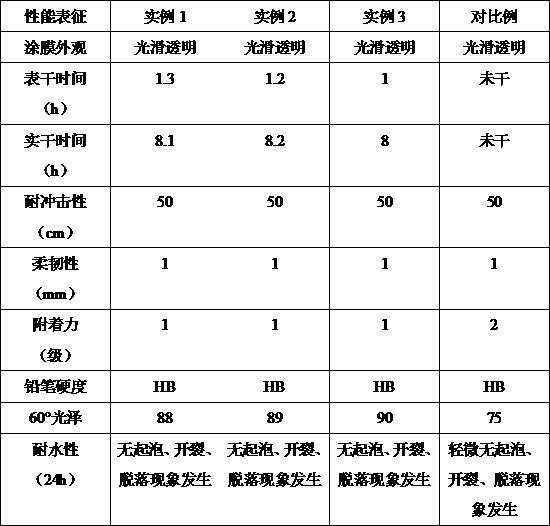

Examples

example 1

[0025] Take 200g of soybean oil and 100g of rosin oil into a flask, heat to 70°C, keep stirring at 300r / min for 20min, cool to room temperature to obtain solvent oil, take 50g of isooctanoic acid, add it to 200g of solvent oil, and stir at 300r / min for 20min , then add 60g of 15% sodium hydroxide solution dropwise at 1g / min, heat to 70°C after the dropwise addition, keep stirring for 3h, let stand for 1h to separate layers and remove the lower water layer, then adjust the pH to 6.5, to obtain saponified oil, add 60g mass fraction of 10% vanadium trichloride solution, 100g mass fraction of 10% zirconium oxychloride solution, and 90g mass fraction of 10% cerium chloride solution to the saponified oil at 1mL / min After the dropwise addition, keep stirring for 3 hours, let stand for 1 hour to separate layers and remove the lower water layer, then mix with 500 mL of deionized water at a temperature of 80°C, clean with 100W ultrasonic waves for 10 minutes, let stand for 1 layer and re...

example 2

[0027] Take 250g of soybean oil and 150g of rosin oil into a flask, heat to 80°C, keep stirring at 350r / min for 25min, cool to room temperature to obtain solvent oil, take 75g of isooctanoic acid, add it to 250g of solvent oil, and stir at 350r / min for 25min , then add 90g of 15% sodium hydroxide solution dropwise at 1g / min, heat to 75°C after the dropwise addition, keep stirring for 4h, let stand for 2h to separate layers and remove the lower water layer, then adjust the pH to 7.0, to get saponified oil, add dropwise 90g mass fraction of 10% vanadium trichloride solution, 150g mass fraction of 10% zirconium oxychloride solution, 135g mass fraction of 10% cerium chloride solution in saponified oil at 1mL / min After the dropwise addition, keep stirring for 4 hours, let stand for 1 hour to separate and remove the lower water layer, then mix with 650 mL of deionized water at a temperature of 85°C, clean with 100W ultrasonic wave for 15 minutes, let stand for 1 layer and remove the ...

example 3

[0029] Take 300g of soybean oil and 200g of rosin oil into a flask, heat to 90°C, keep stirring at 400r / min for 30min, cool to room temperature to obtain solvent oil, take 100g of isooctanoic acid, add it to 300g of solvent oil, and stir at 400r / min for 30min , then add 120g of 15% sodium hydroxide solution dropwise at 2g / min. After the dropwise addition, heat to 80°C, keep stirring for 5h, let stand for 2h to separate layers and remove the lower water layer, and then use isooctanoic acid to adjust the pH to 7.5, to obtain saponified oil, add 120g mass fraction of 10% vanadium trichloride solution, 200g mass fraction of 10% zirconium oxychloride solution, and 180g mass fraction of 10% cerium chloride solution in saponified oil at 2mL / min After the dropwise addition, keep stirring for 5 hours, let stand for 2 hours to separate layers and remove the lower water layer, then mix with 800mL deionized water at a temperature of 90°C, clean with 100W ultrasonic waves for 20 minutes, le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com