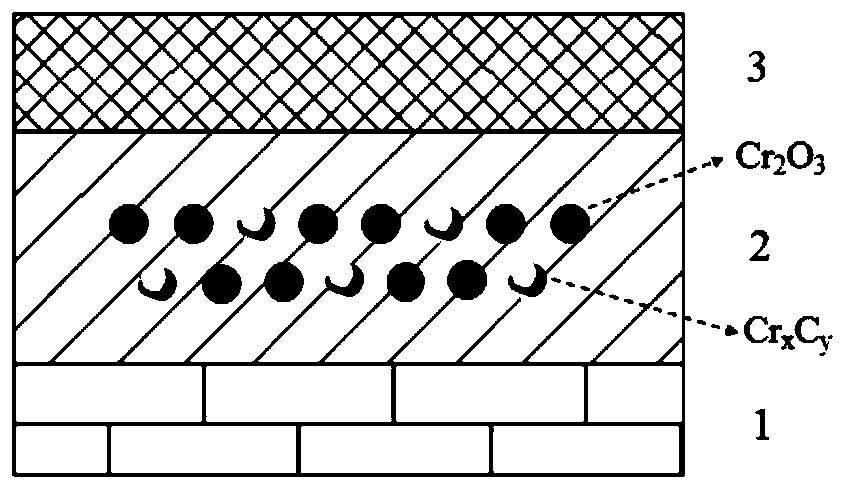

Chromium carbide dispersed chromium oxide/alumina composite hydrogen barrier coating material and preparation method

A technology of aluminum oxide coating and composite coating, which is applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve the problem of weak bonding between coating and substrate, achieve good electroplating effect, and obtain materials The effect of easy access and convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the chromium carbide dispersed chromium oxide / alumina composite hydrogen barrier coating material proposed by the present invention comprises the following steps:

[0024] (1) Polish the surface of the stainless steel with sandpaper to 7000#, then polish it with flannelette until the surface of the stainless steel is bright, and seal the remaining 5 surfaces of the stainless steel with insulating tape to obtain a bright stainless steel substrate;

[0025] (2) Using the pulse electrochemical deposition method, put the stainless steel substrate in the above step (1) into the electroplating solution, the composition of the electroplating solution is: 0.5mol / L of CrCl3 ·6H 2 O, 0.8mol / L HCOOH, 0.65mol / L H 3 BO 3 , 1mol / L KCl, 1mol / L NH 4 Cl, 10g / L NH 4 Br and 0.2g / L sodium lauryl sulfate, the pH of the plating solution is 2, the temperature of the plating solution is 15-45°C, and the current density in the plating solution is 30-50A / dm 2 , the ...

Embodiment 1

[0030] (1) Polish the surface of the stainless steel with sandpaper to 7000#, then polish it with flannelette until the surface of the stainless steel is bright, and seal the remaining 5 surfaces of the stainless steel with insulating tape to obtain a bright stainless steel substrate;

[0031] (2) Using the pulse electrochemical deposition method, put the bright surface of the stainless steel substrate in the above step (1) into the electroplating solution, the composition of the electroplating solution is: 0.5mol / L of CrCl 3 ·6H 2 O, 0.8mol / L HCOOH, 0.65mol / L H 3 BO 3 , 1mol / L KCl, 1mol / L NH 4 Cl, 10g / L NH 4 Br and 0.2g / L sodium lauryl sulfate, the pH value of the plating solution is 2, the temperature of the plating solution is 15°C, and the current density in the plating solution is 30A / dm 2 , the pulse duty ratio is 50%, the electroplating time is 10 minutes, a Cr-C coating is obtained on the bright surface of the stainless steel substrate, and the thickness of the coa...

Embodiment 2

[0036] (1) Polish the surface of the stainless steel with sandpaper to 7000#, then polish it with flannelette until the surface of the stainless steel is bright, and seal the remaining 5 surfaces of the stainless steel with insulating tape to obtain a bright stainless steel substrate;

[0037] (2) Using the pulse electrochemical deposition method, put the bright surface of the stainless steel substrate in the above step (1) into the electroplating solution, the composition of the electroplating solution is: 0.5mol / L of CrCl 3 ·6H 2 O, 0.8mol / L HCOOH, 0.65mol / L H 3 BO 3 , 1mol / L KCl, 1mol / L NH 4 Cl, 10g / L NH 4 Br and 0.2g / L sodium lauryl sulfate, the pH value of the plating solution is 2, the temperature of the plating solution is 30°C, and the current density in the plating solution is 45A / dm 2 , the pulse duty ratio is 70%, the electroplating time is 30 minutes, a Cr-C coating is obtained on the bright surface of the stainless steel substrate, and the thickness of the coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com