Paper product containing graphene and preparation method thereof

A graphene and graphene dispersion technology, which is applied in paper, papermaking, textiles and papermaking, can solve the problems of low pulping yield and low kappa value, and achieve high fiber yield, low kappa value, good hygienic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

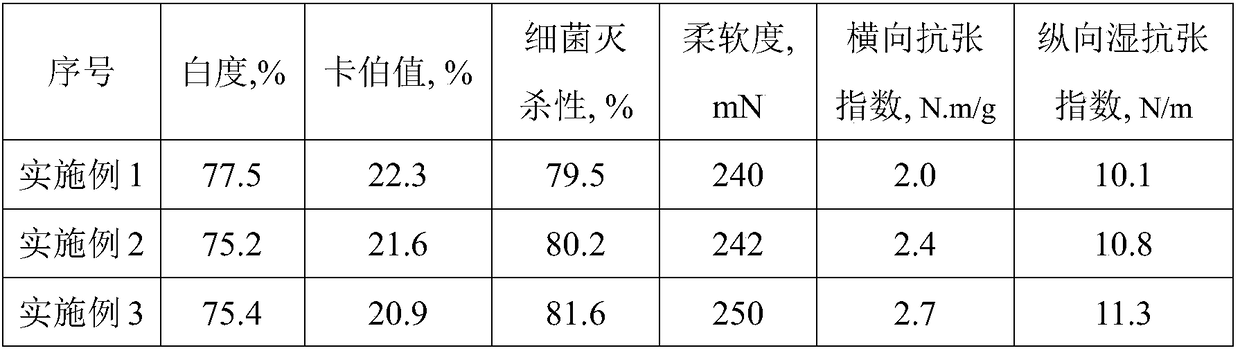

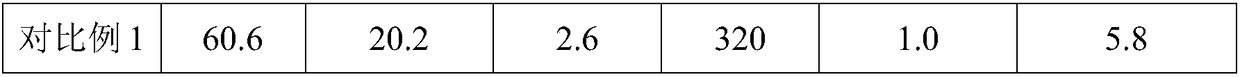

Examples

Embodiment 1

[0028] The present embodiment provides a kind of preparation method of the toilet paper product containing graphene, comprises the following steps:

[0029] S1. Deslagging the medicinal plants, removing the silt and dust therein, drying until the water content is 20%, performing screw extrusion on the medicinal plants, and then set aside;

[0030] S2. Place the extruded medicinal plants obtained in step S1 in an ultrasonic reactor, add a 30% ethanol solution, the liquid ratio is 1:6, the cooking temperature is 120° C., and the time is 50 minutes before discharging. Obtain bleached pulp; the process parameters of the ultrasonic reactor are: the power of the ultrasonic reactor is 1500W, and the frequency is 25KHz;

[0031] S3. Place the bleached pulp obtained in step S2 in a displacement washer, use a 50% ethanol solution at normal temperature and pressure to carry out two-stage displacement washing, the washing liquid ratio is 1:4, and then wash it with water to obtain medicina...

Embodiment 2

[0037] The present embodiment provides a kind of preparation method of the paper product containing graphene, and specific operation steps are as follows:

[0038] S1. The medicinal plants are subjected to deslagging treatment, after removing silt and dust therein, and dried until the water content is 30%, after the above-mentioned medicinal plants are subjected to screw extrusion treatment, they are set aside; the compression ratio of the screw extrusion treatment is 2:1;

[0039] S2. Place the extruded medicinal plants obtained in step S1 in an ultrasonic reactor, add a 50% ethanol solution, the liquid ratio is 1:8, the cooking temperature is 100° C., and the time is 60 minutes before discharging. Obtain bleached pulp; the process parameters of the ultrasonic reactor are: the power of the ultrasonic reactor is 1400W, and the frequency is 30KHz;

[0040] S3. Place the bleached slurry obtained in step S2 in a displacement washer, use a 60% ethanol solution at normal temperatu...

Embodiment 3

[0046] The present embodiment provides a kind of preparation method of the paper product containing graphene, and specific operation steps are as follows:

[0047] S1. The medicinal plants are subjected to slag removal treatment, after removing silt and dust therein, dried until the water content is 25%, after the above-mentioned medicinal plants are subjected to screw extrusion treatment, for subsequent use; the compression ratio of the screw extrusion treatment is 1.5:1;

[0048] S2. Place the extruded medicinal plants obtained in step S1 in an ultrasonic reactor, add a 40% ethanol solution, the liquid ratio is 1:7, the cooking temperature is 110° C., and the time is 55 minutes before discharging. Obtain bleached pulp; the process parameters of the ultrasonic reactor are: the power of the ultrasonic reactor is 1450W, and the frequency is 30KHz;

[0049] S3. Place the bleached slurry obtained in step S2 in a displacement washer, and use an ethanol solution with a concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com