Modified polyamide reverse osmosis membrane and manufacturing method thereof

A technology of reverse osmosis membrane and manufacturing method, applied in the field of membrane separation, to achieve the effects of avoiding easy agglomeration, low manufacturing cost, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

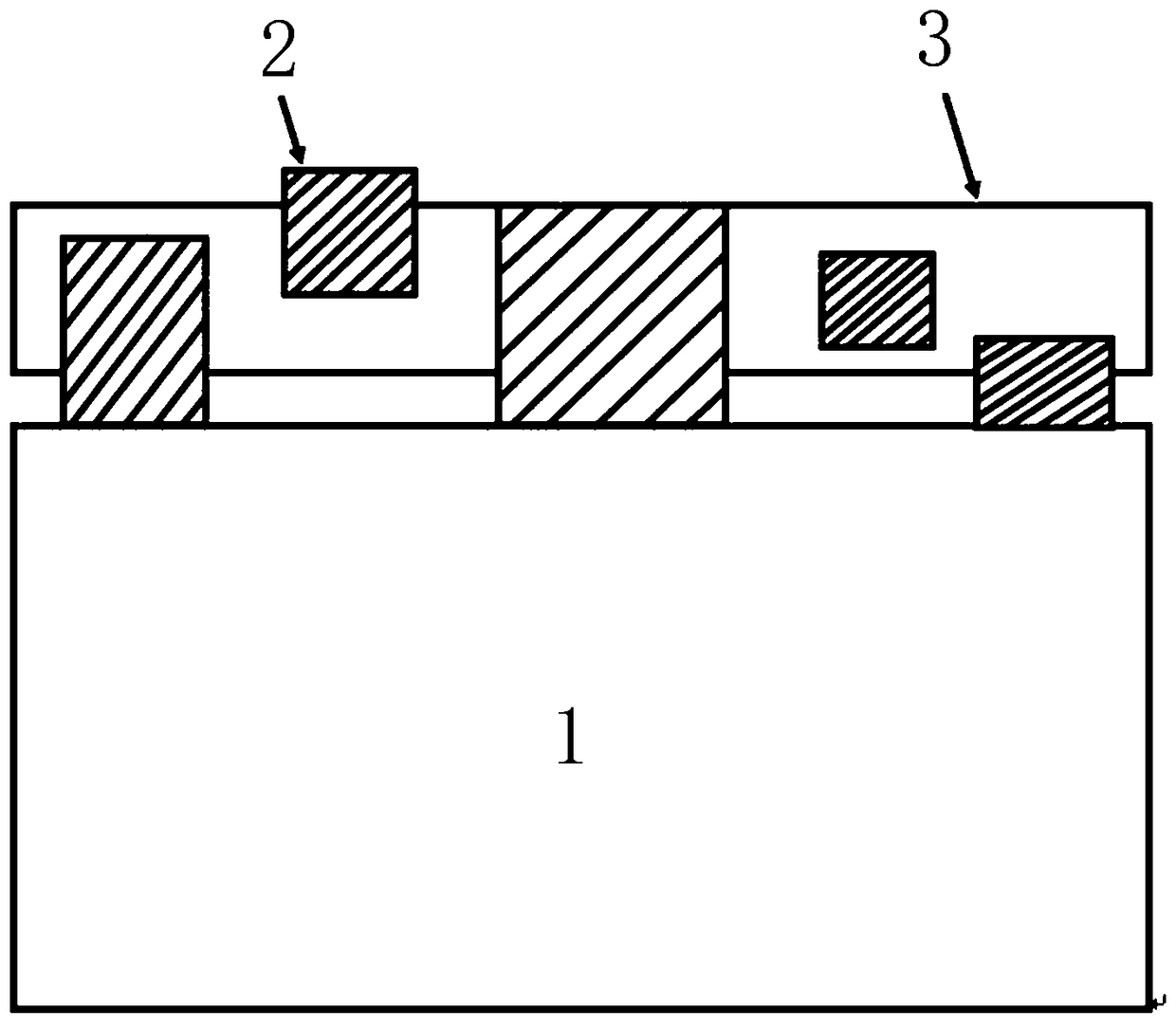

Image

Examples

Embodiment 1

[0032] A method for manufacturing a modified polyamide ultra-low pressure reverse osmosis membrane embedded with silica gel nanoparticles, comprising the following steps:

[0033] (1) Aqueous solution A of polyfunctional amines: Dissolve 2 g of m-phenylenediamine in 100 g of pure water, and add 2 g of triethylamine in sequence, then adjust solution A to pH 10.0 with pH 1 aqueous hydrochloric acid solution, and stir evenly;

[0034](2) Organic solution B for configuring polyfunctional acyl halides and silanes and / or alkoxides: add 0.15 g of trimesoyl chloride and 0.02 g of silicon tetrachloride successively in 100 g of solvent oil (ISOPAR-G), and stir Uniform and completely dissolved, wherein the concentration of trimesoyl chloride is 0.15wt%, and the concentration of silicon tetrachloride is 0.02wt%;

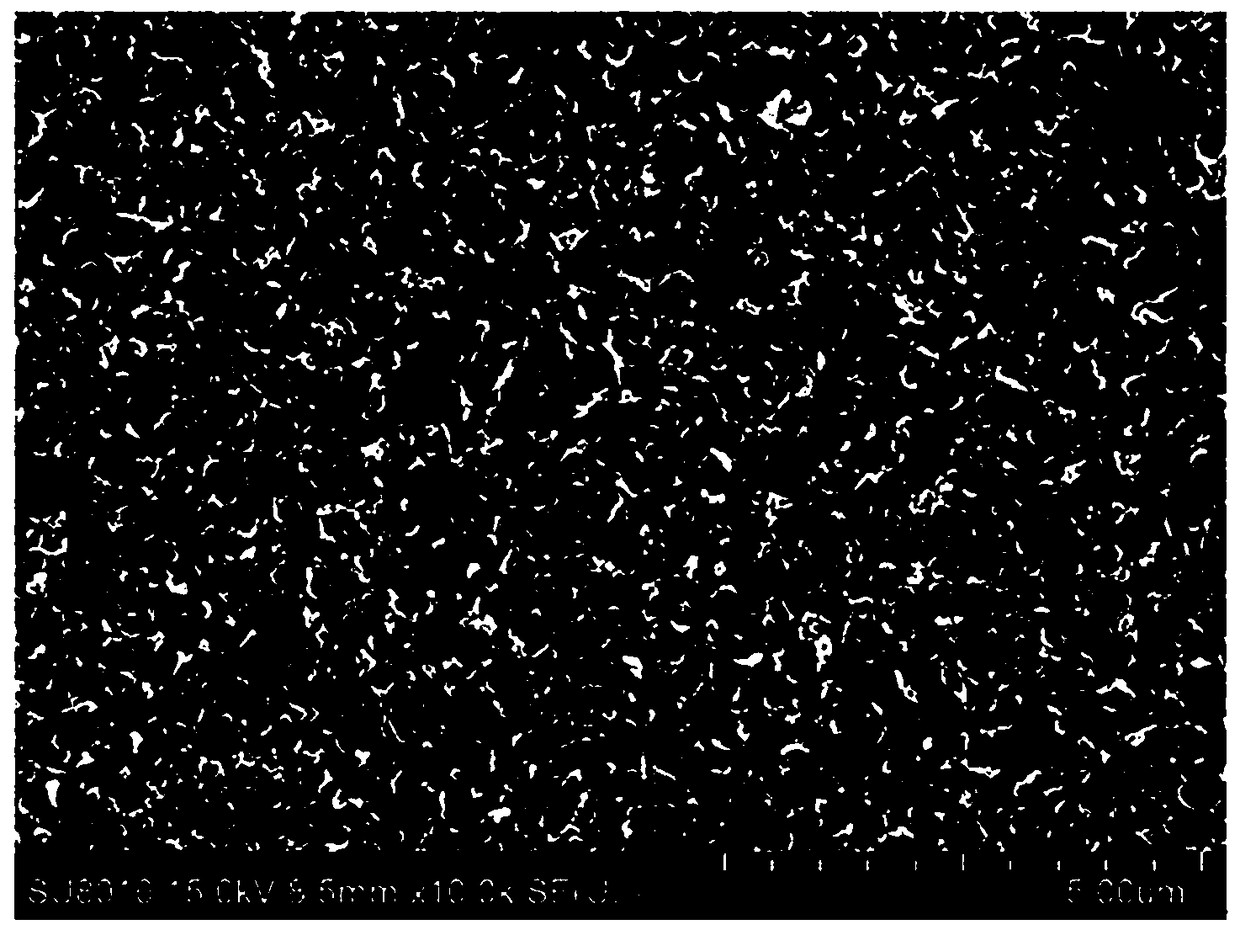

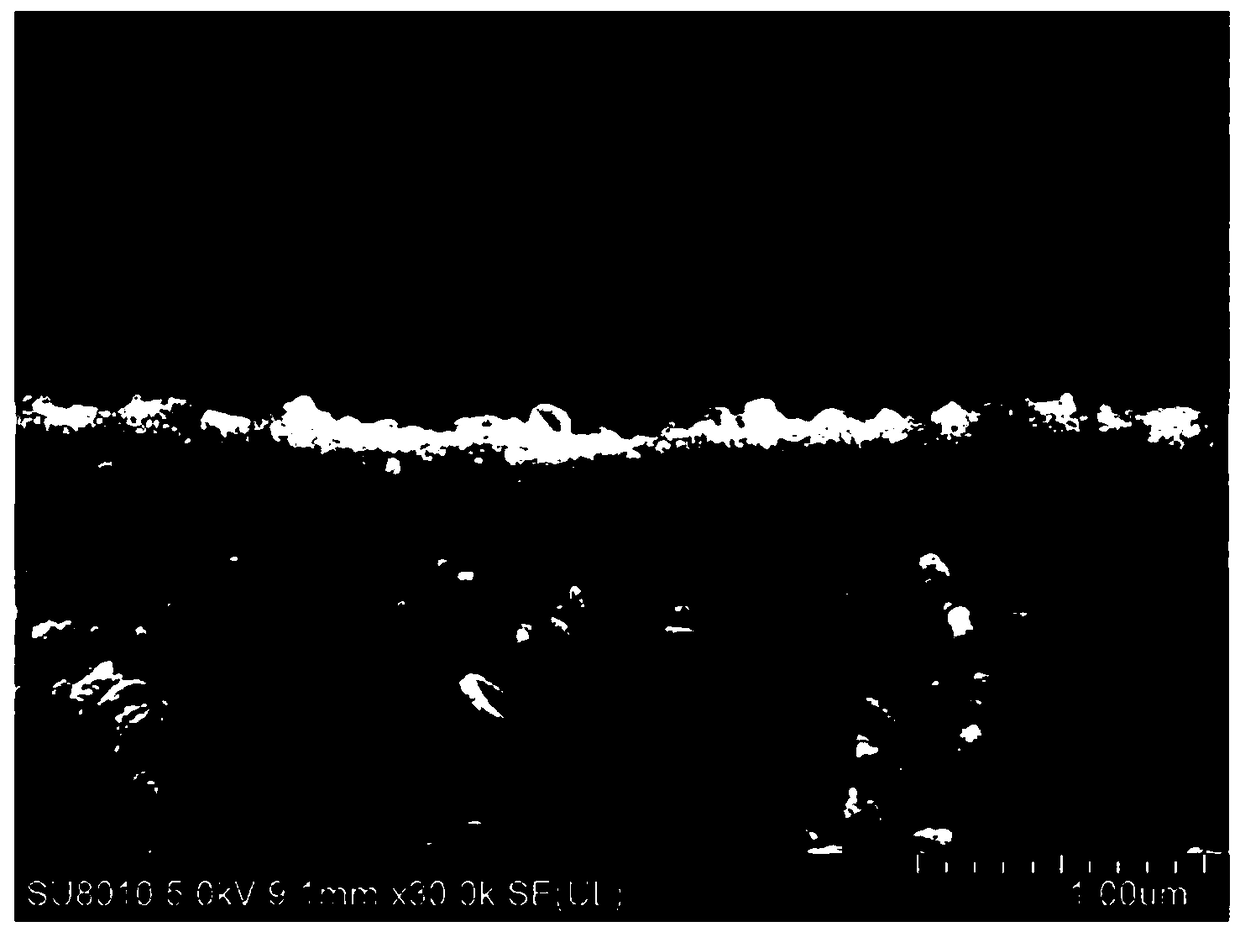

[0035] (3) Interfacial polymerization reaction: put the cleaned wet porous polysulfone support layer (pore size 0.01 μm) into solution A, contact time is 120s, dry the water dro...

Embodiment 2

[0046] Except replacing 0.02g of silicon tetrachloride in step 2) with 0.01g of titanium ethoxide and 0.01g of silicon tetrachloride, a composite polyamide reverse osmosis membrane was produced according to the same formula and process as in Example 1.

[0047] The membrane has a pure water flux of 7.4L m measured at 5-15bar -2 h -1 · bar -1 , the water flux to 25℃, 2000ppm brine solution is 6.1L m -2 h -1 · bar -1 , the sodium chloride rejection rate is 98.3%, and the results are shown in Table 1.

Embodiment 3

[0049] Except that the silicon tetrachloride of 0.02g in step 2) is replaced by the phenyl silicon trichloride of 0.01g and the butyl titanate of 0.01g, make composite polyamide reverse osmosis according to the formula and process identical with embodiment 1 membrane.

[0050] The pure water flux measured by the membrane at 5-15bar is 8.2L m -2 h -1 · bar -1 , the water flux to 25℃, 2000ppm brine solution is 7.0L m -2 h -1 · bar -1 , the sodium chloride rejection rate is 97.6%, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com