Method for preparing tungsten doped zinc oxide nanosphere through liquid phases

A zinc oxide nano- and tungsten-doped technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of cumbersome preparation process and difficult regulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

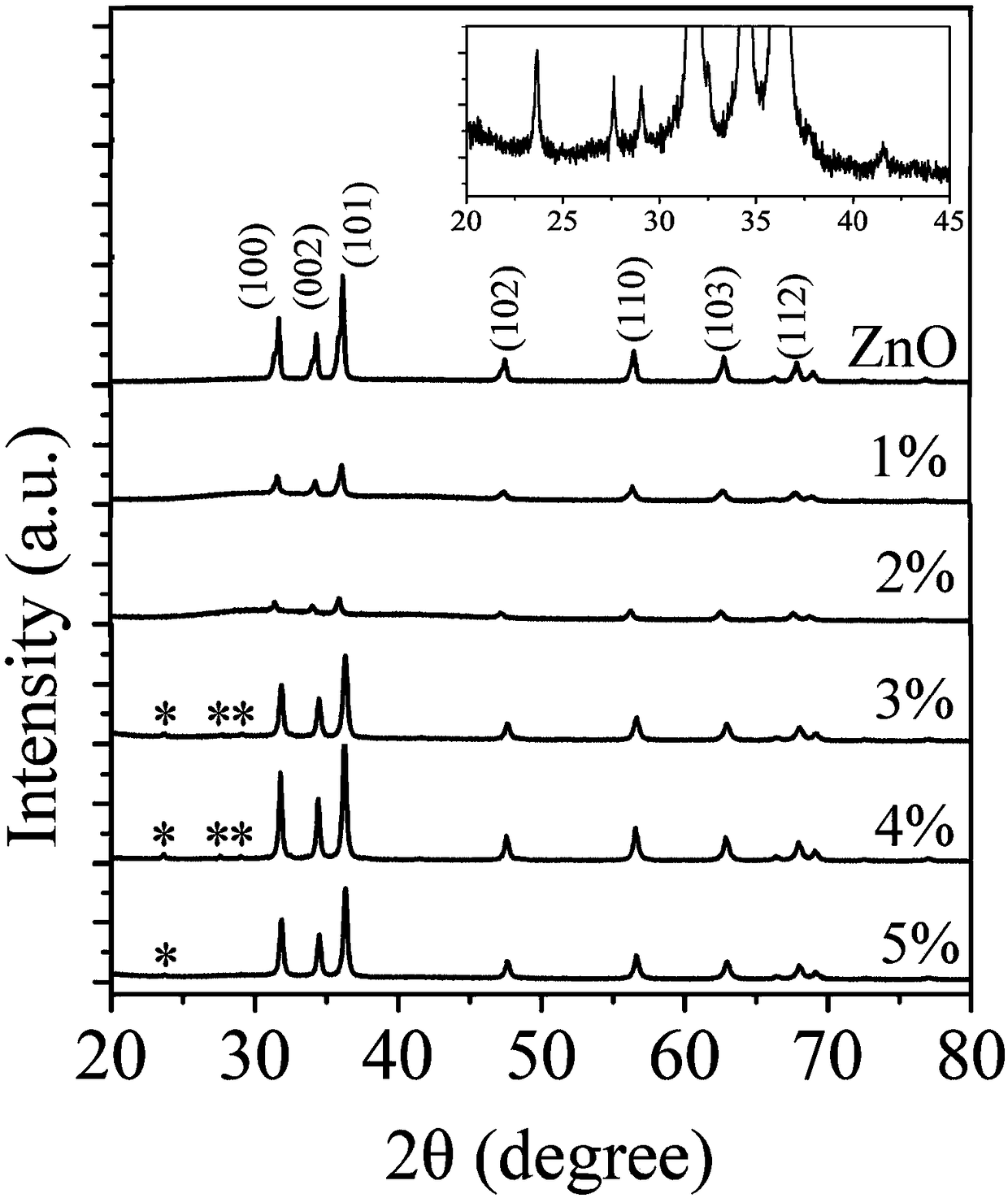

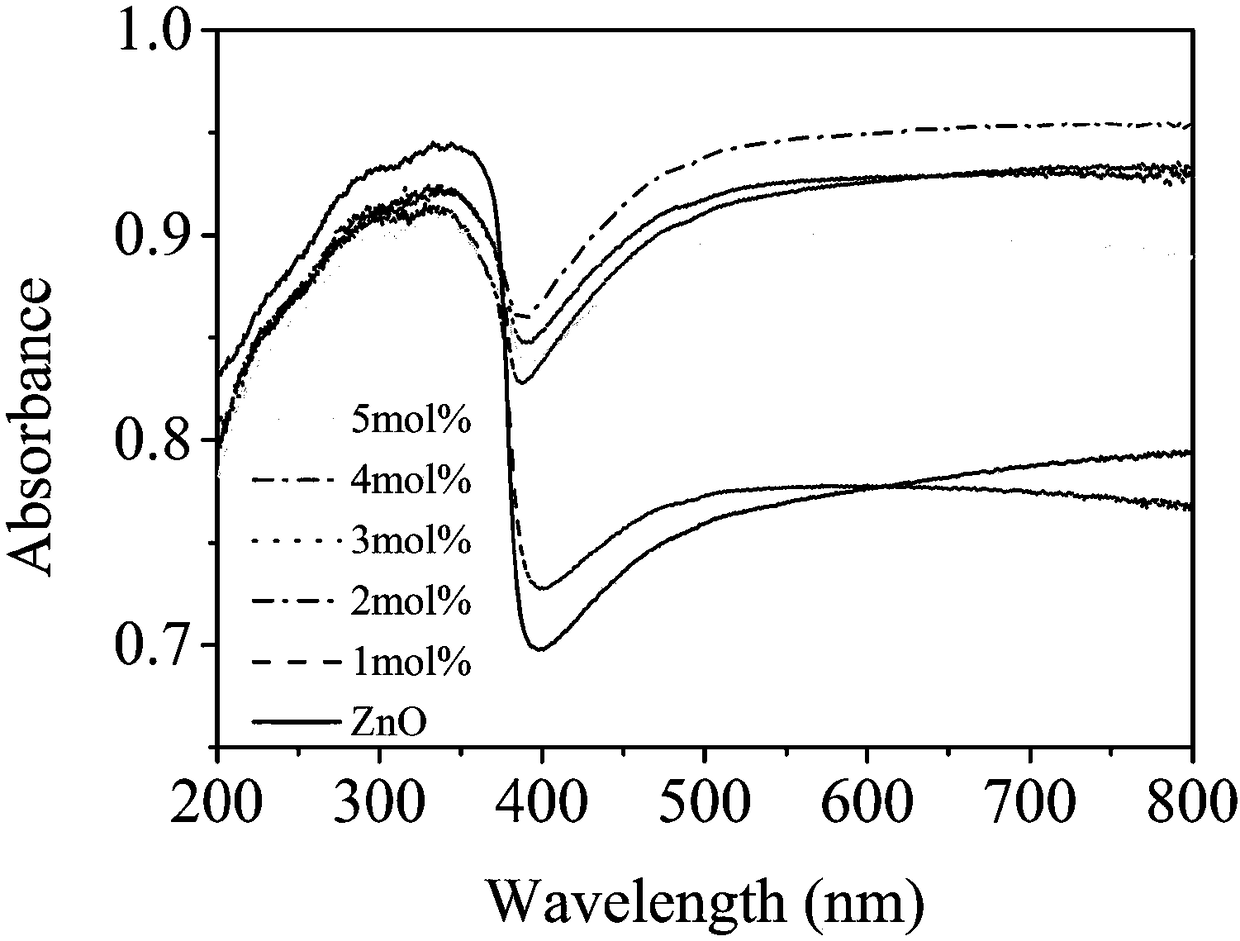

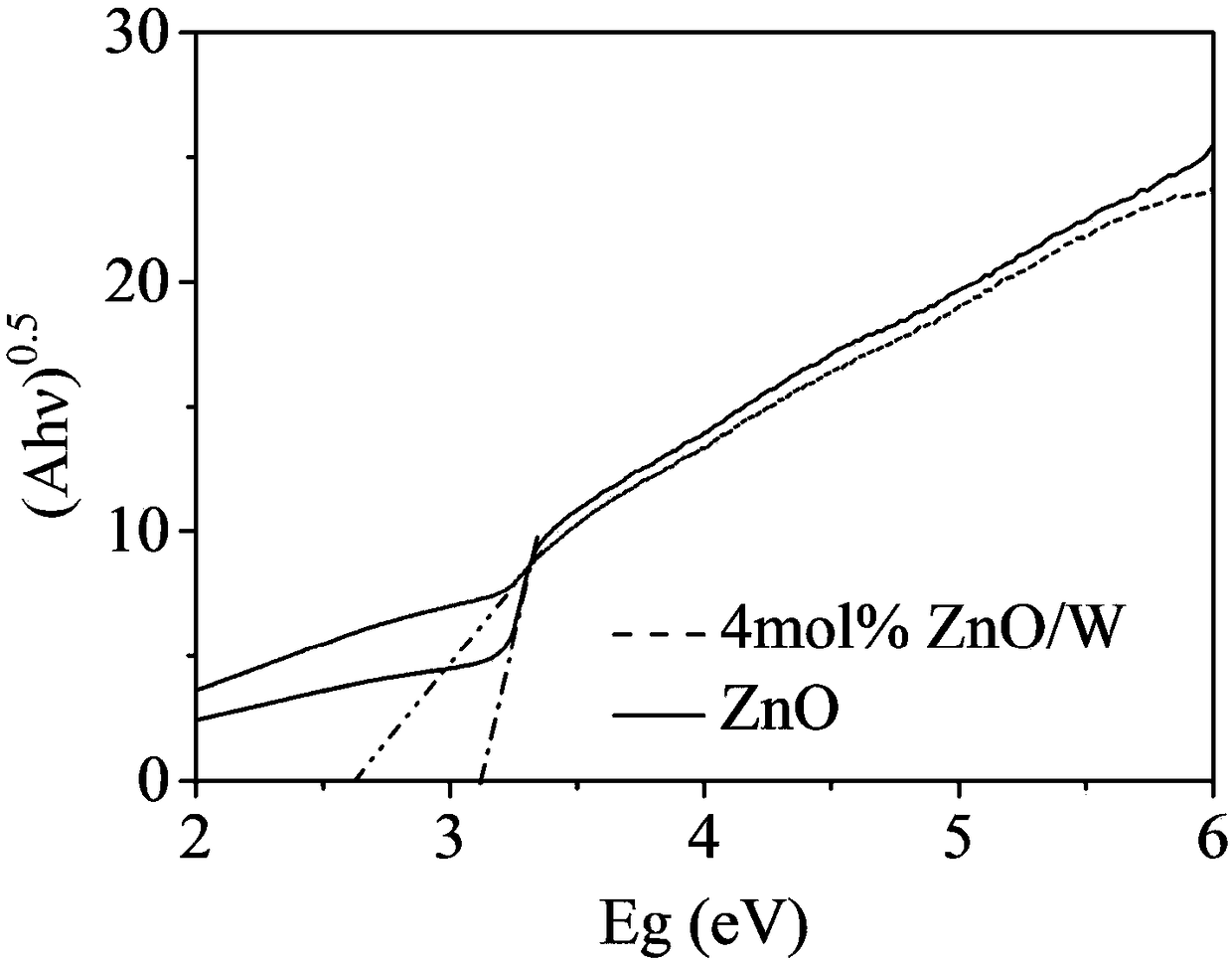

[0015] Example 1 A method for preparing tungsten-doped zinc oxide nanospheres in liquid phase

[0016] The preparation method of the tungsten-doped zinc oxide nanosphere photocatalytic material includes four stages of preparation of zinc oxide / tungsten sol, low-temperature drying, high-temperature annealing and grinding.

[0017] (1) Preparation of zinc oxide / tungsten sol

[0018] Dissolve 2.3g of zinc acetate and 0g, 0.03464g, 0.06927g, 0.10391g, 0.13854g, 0.17318g of sodium tungstate in a mixed solution of 10 mL of deionized water and 20 mL of ethanol, heat to 65°C and stir magnetically for 10 min , and then 1 mL of ethanolamine was added dropwise, and magnetically stirred at 65°C for 2 h to obtain a uniform white sol, which was left at room temperature for 36 h before use.

[0019] (2), low temperature drying

[0020] The sol was dried in a drying oven at 60 °C for 2 h.

[0021] (3), tungsten doped zinc oxide sol infiltration and high temperature annealing

[0022] Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com