Method for synthesizing bismuth trioxide-cuprous oxide nano-composite through mechanical milling thermal treatment two-step method

A nanocomposite, bismuth trioxide technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Problems such as poor crystallinity and easy agglomeration of products achieve the effects of easy industrial production, convenient operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] According to the molar ratio of 2:1:3, weigh 0.01 mole of sodium bismuthate dihydrate, 0.005 mole of basic copper carbonate and 0.015 mole of dihydrate oxalic acid and add 50 zirconia grinding balls with a diameter of 6mm and 8 zirconia grinding balls with a diameter of 10mm. In a 50mL zirconia ball mill jar, the ball mill was continuously milled in a QM-3SP04 planetary high-energy ball mill at 480rpm for 2 hours, and the product obtained from the milling reaction was washed with distilled water, centrifuged and vacuum-dried at 60°C and 0.1Mpa vacuum for 2 hours. hours, the reaction product was obtained.

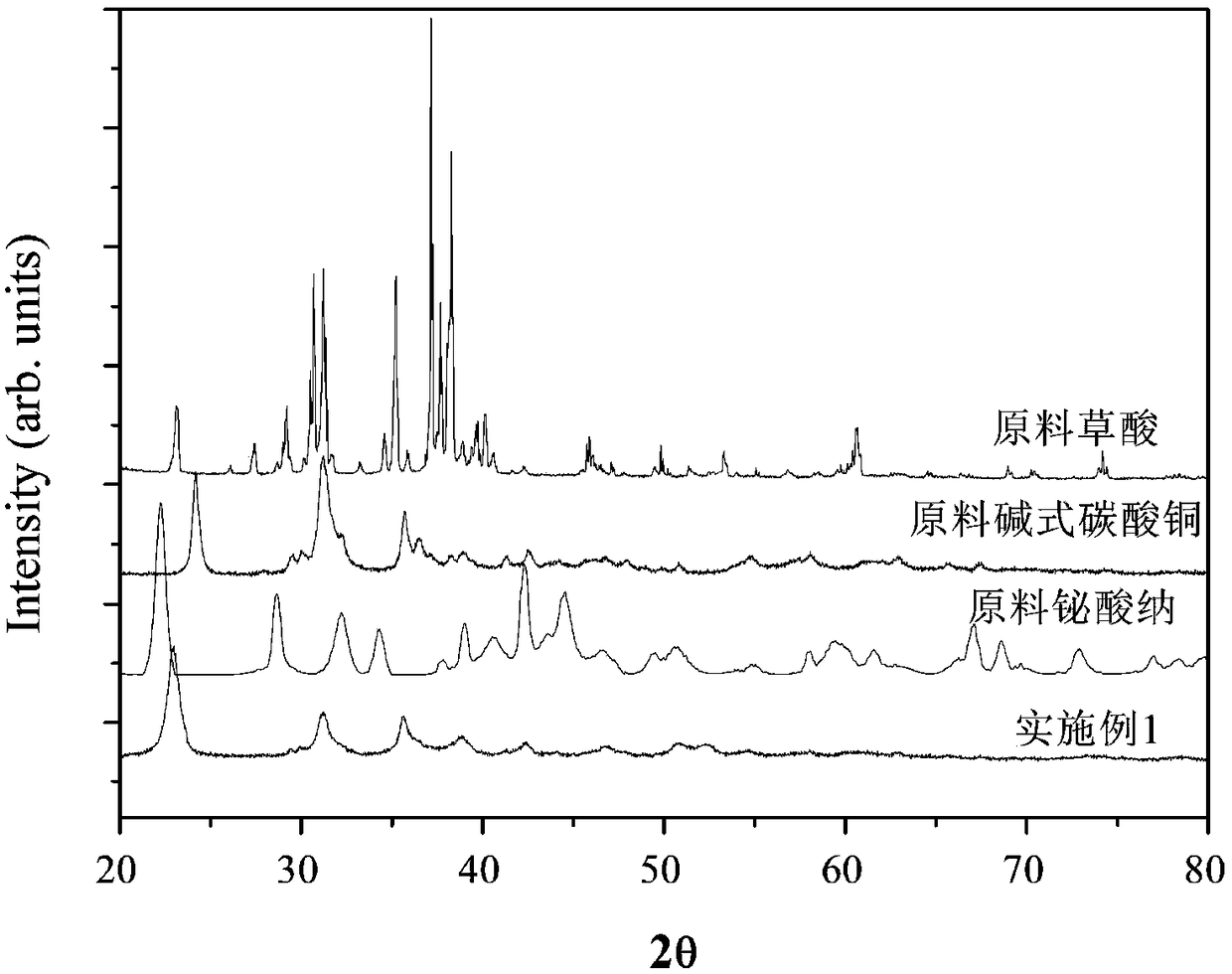

[0020] Carry out XRD analysis respectively to the reaction product of present embodiment and reaction raw material (see attached figure 1 ),From figure 1 It can be seen that in the XRD spectrum of the reaction product, the characteristic diffraction peaks of the reaction raw materials sodium bismuthate dihydrate and basic copper carbonate are not found, indicating th...

Embodiment 2

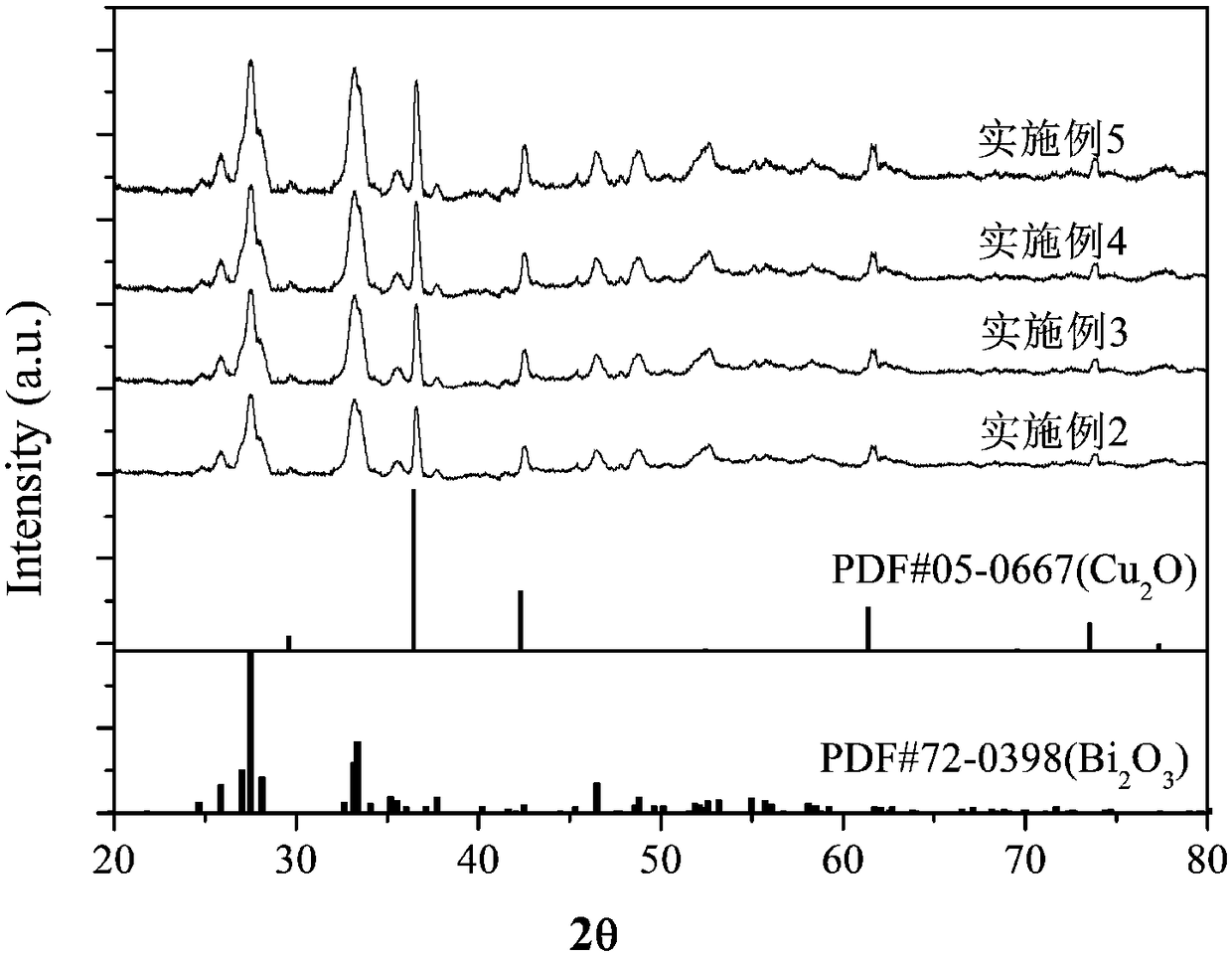

[0022] According to the molar ratio of 2:1:3, weigh 0.01 mole of sodium bismuthate dihydrate, 0.005 mole of basic copper carbonate and 0.015 mole of dihydrate oxalic acid and add 50 zirconia grinding balls with a diameter of 6mm and 8 zirconia grinding balls with a diameter of 10mm. In a 50mL zirconia ball mill jar, mill continuously in a QM-3SP04 planetary high-energy ball mill at 480rpm for 2 hours, put the product obtained from the ball mill reaction into a crucible with a lid and calcinate at 450°C for 1 hour, after cooling, use distilled water to grind the product Washing, centrifugation and vacuum drying at 60° C. and 0.1 Mpa vacuum for 2 hours to obtain the final product.

Embodiment 3

[0024]According to the molar ratio of 2:1:3, weigh 0.01 mole of sodium bismuthate dihydrate, 0.005 mole of basic copper carbonate and 0.015 mole of dihydrate oxalic acid and add 50 zirconia grinding balls with a diameter of 6mm and 8 zirconia grinding balls with a diameter of 10mm. In a 50mL zirconia ball mill jar, mill continuously in a QM-3SP04 planetary high-energy ball mill at 480rpm for 2 hours, put the product obtained from the ball mill reaction into a crucible with a lid and calcinate at 450°C for 2 hours, after cooling, use distilled water to grind the product Washing, centrifugation and vacuum drying at 60° C. and 0.1 Mpa vacuum for 2 hours to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com