Oil resistant epoxy resin and preparation method thereof

An epoxy resin and oil-resistant technology, which is applied in the field of oil-resistant epoxy resin and its preparation, can solve problems such as insufficient oil resistance of epoxy resin, and achieve the effect of improving oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

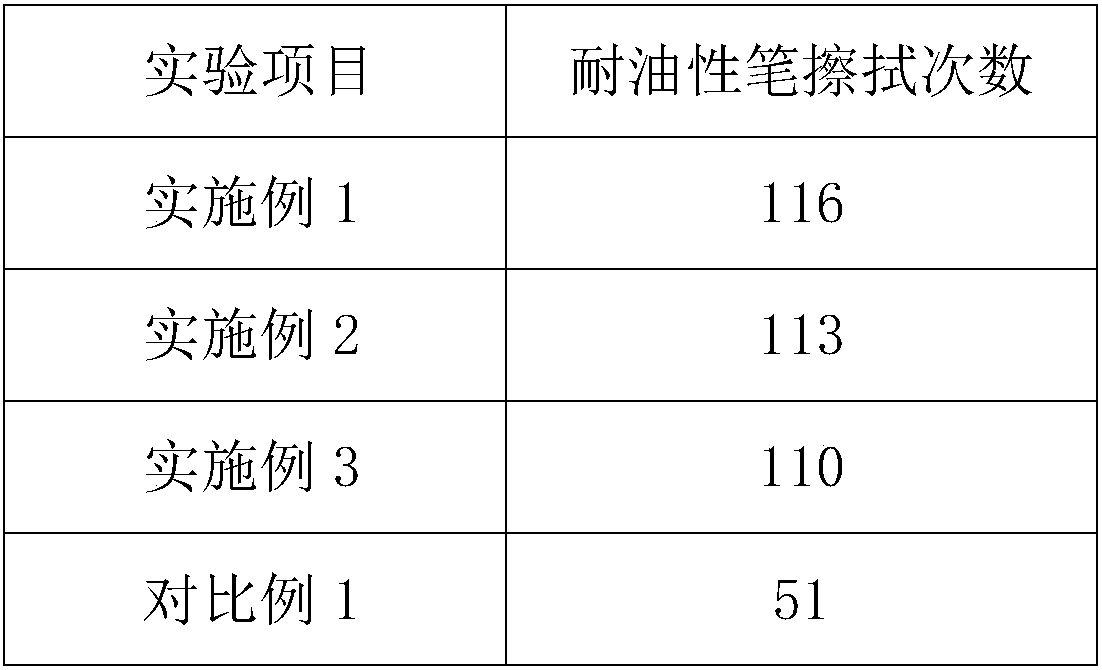

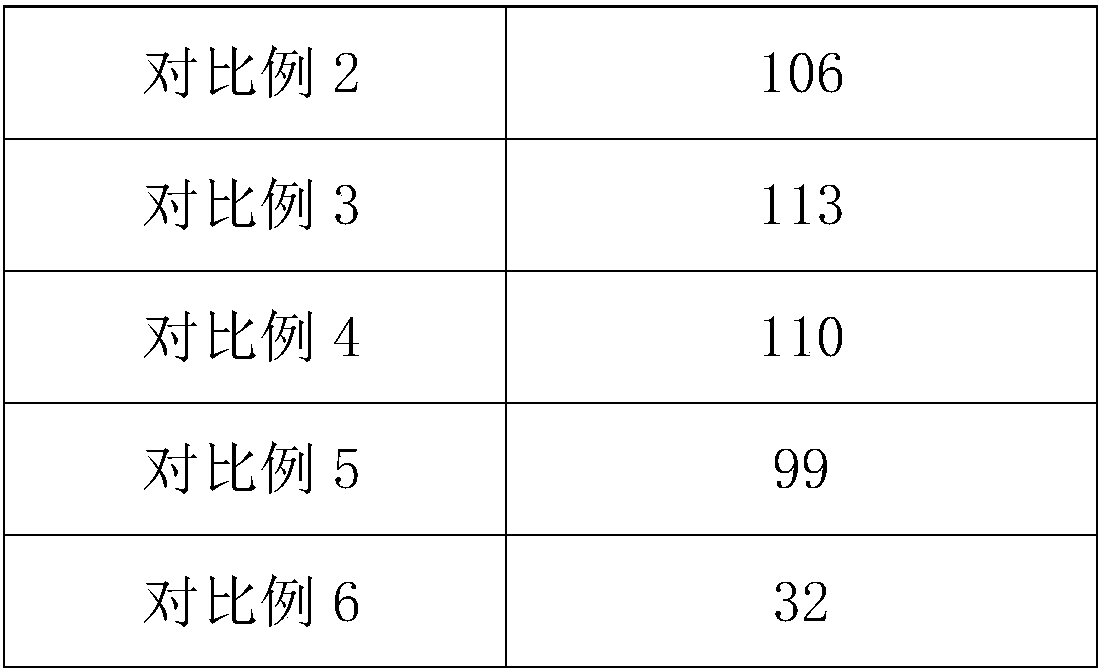

Examples

preparation example Construction

[0021] The preparation method of described oil resistant epoxy resin, comprises the steps:

[0022] S1. Mix epoxy resin, silicone rubber, fluororubber, trioctyl trimellitate, perfluoroalkyl acrylate, polyphenylene sulfide, coumarone resin, and polyamide resin evenly, at 850-1050r / min Stir at a rotating speed for 10-30min, heat up to 80-90°C, keep warm for 20-40min, then add dioctyl phthalate, trioctyl trimellitate, low-density polyethylene, isocyanate, polyadipic acid, metaboric acid Sodium, dioctyl phthalate, aluminum polyphosphate, zinc oxide, dicumyl peroxide, nano-alumina, dibutyltin dilaurate, methacrylic acid, carbon nanotubes, polyphosphate are mixed evenly, ball milled After cooling to room temperature to obtain the base material;

[0023] S2. Mix zinc stearate, fluorine micropowder, and oil-resistant modification additives evenly, heat up to 60-80°C, keep warm for 10-20min, then add silane coupling agent KH-570, mix evenly, and continue to heat up to 110-120°C , kee...

Embodiment 1

[0027]An oil-resistant epoxy resin, in parts by weight, comprising the following raw materials: 100 parts of epoxy resin, 20 parts of silicone rubber, 6 parts of fluororubber, 4.5 parts of trioctyl trimellitate, 3.5 parts of perfluoroalkyl acrylate 2.5 parts of polyphenylene sulfide, 4.5 parts of coumarone resin, 6 parts of polyamide resin, 6 parts of dioctyl phthalate, 4 parts of trioctyl trimellitate, 3 parts of low density polyethylene, isocyanate 6 parts, 6 parts of polyadipate, 4 parts of sodium metaborate, 3 parts of dioctyl phthalate, 6 parts of aluminum polyphosphate, 3.5 parts of zinc oxide, 2.5 parts of dicumyl peroxide, nano-alumina 4 parts, 3 parts of dibutyltin dilaurate, 6 parts of methacrylic acid, 4 parts of carbon nanotubes, 3 parts of polyphosphate, 5 parts of zinc stearate, 13 parts of fluorine micropowder, 2 parts of silane coupling agent KH-570 12 parts of oil resistance modification additive.

[0028] The oil-resistant modification additive is prepared a...

Embodiment 2

[0034] An oil-resistant epoxy resin, in parts by weight, comprising the following raw materials: 80 parts of epoxy resin, 25 parts of silicone rubber, 4 parts of fluororubber, 6 parts of trioctyl trimellitate, 2 parts of perfluoroalkyl acrylate 4 parts of polyphenylene sulfide, 3 parts of coumarone resin, 8 parts of polyamide resin, 3 parts of dioctyl phthalate, 6 parts of trioctyl trimellitate, 1 part of low density polyethylene, isocyanate 9 parts, 4 parts of polyadipate, 6 parts of sodium metaborate, 1 part of dioctyl phthalate, 9 parts of aluminum polyphosphate, 2 parts of zinc oxide, 4 parts of dicumyl peroxide, nano-alumina 3 parts, 5 parts of dibutyltin dilaurate, 4 parts of methacrylic acid, 6 parts of carbon nanotubes, 1 part of polyphosphate, 6 parts of zinc stearate, 12 parts of fluorine micropowder, 3 parts of silane coupling agent KH-570 , 8 parts of oil resistance modification additives.

[0035] The oil-resistant modification additive is prepared according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com