Water-based auxiliary material capable of improving application properties of water-based metal and pearl finish and preparation method of water-based auxiliary material

A constructable and water-based technology, applied in latex paints, coatings, etc., can solve the problems of rough surface, inability to achieve spray uniformity, local accumulation, etc., to achieve smooth and smooth surface, excellent board effect, and maintain board effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

[0054] Embodiment 1 preparation of dimer acid modified organobentonite

[0055] (1) According to the ratio of sodium bentonite: calcium bentonite weight ratio of 5:1, take sodium bentonite and calcium bentonite respectively, mix them, place them in a reactor, add isopropanol 10 times the weight of bentonite and stir , to obtain bentonite suspension;

[0056] (2) add pre-dissolved dimer acid ethanol solution to the bentonite suspension of step (1), stir evenly, then add sodium persulfate, the weight of described sodium persulfate in the system is 0.15%, heat and reflux to The reaction is complete and the product is isolated;

[0057](3) The product is transferred to a filter press equipment, the filter cake is washed with absolute ethanol for 3 times, then washed with purified water for 3 times, dried at a temperature of 60-80°C, and dried to obtain the product;

[0058] Wherein, the dimer acid concentration in the dimer acid ethanol solution is 6% (v / v), and the added amount...

Embodiment 2

[0059] Embodiment 2 preparation of aqueous auxiliary material

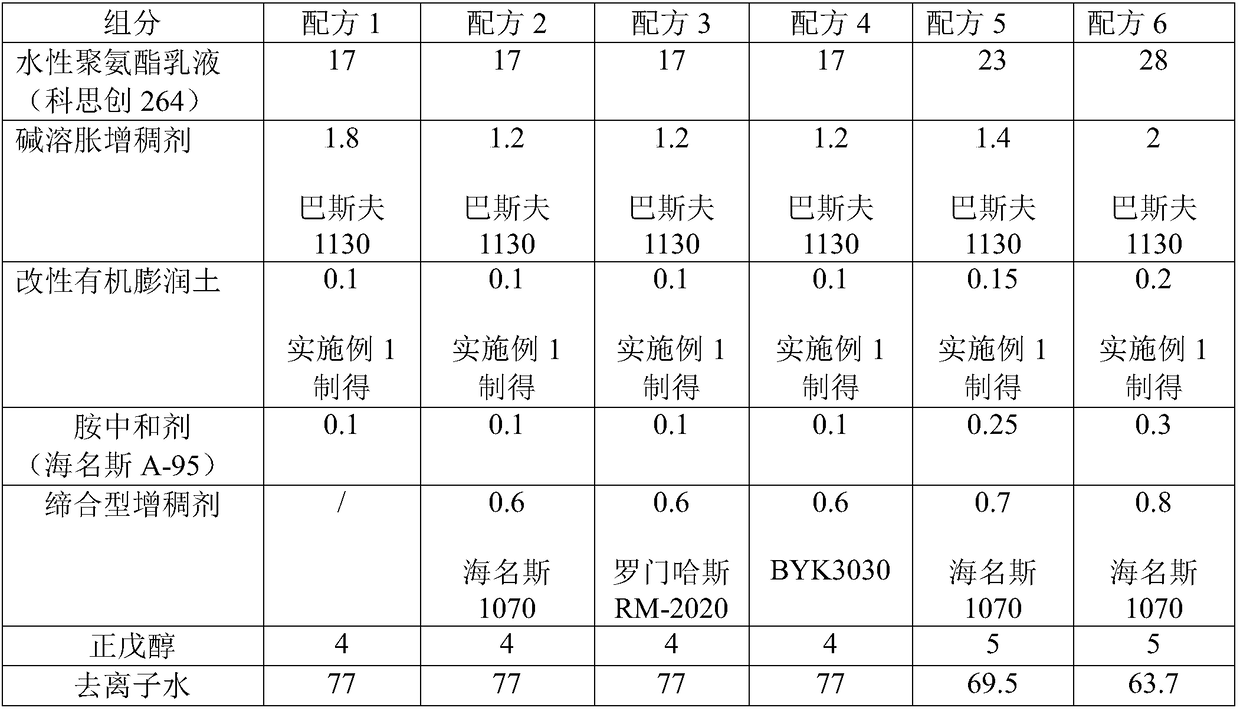

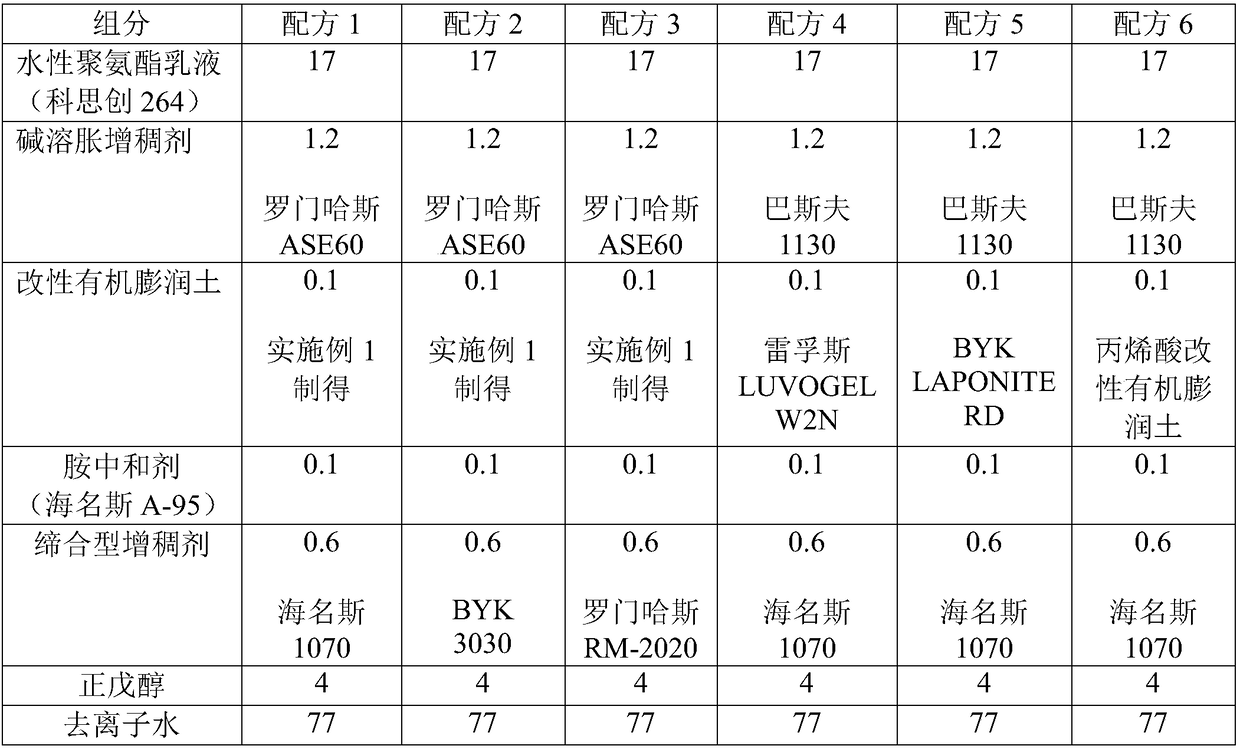

[0060] The formula for the preparation of the water-based auxiliary material in Example 2 is shown in the table.

[0061]

[0062] Preparation:

[0063] (1) Dissolve modified organic bentonite in water to make a 2% (m / v) solution for later use; respectively dissolve amine neutralizer and associative thickener in water to make 20% (m / v) And 50% (m / v) solution standby;

[0064] (2) 2% (m / v) organobentonite diluent, 20% (m / v) of water-based polyurethane emulsion, the organic bentonite dilution that step (1) makes with the speed limit of 450 rev / mins are dropped into successively while stirring Amine diluent and remaining amount of water, stirred for 8 minutes;

[0065] (3) drop into the alkali-swellable thickener of formula quantity in step (2), continue to stir for 8 minutes;

[0066] (4) slowly drip the n-amyl alcohol of formula quantity in step (3), continue to stir for 8 minutes;

[0067] (5) Put the 50% ...

Embodiment 3-8

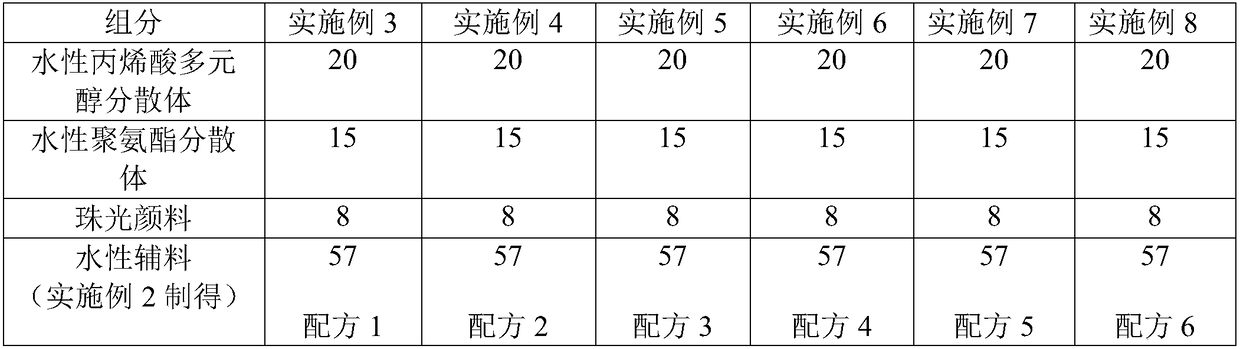

[0074] Embodiment 3-8 water-based metallic paint preparation

[0075] The formula prepared by embodiment 3-8 waterborne metallic paint is as shown in the table.

[0076]

[0077] Preparation: Add water-based acrylic polyol dispersion, water-based polyurethane dispersion, pearlescent pigment, and water-based auxiliary materials sequentially while stirring at 600 rpm according to the formula amount shown in the above table, and stir for 50 minutes to obtain a water-based metallic paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com