Interpenetrating network structure polymer of silicone rubber-fluorocarbon coating and preparation method thereof

A technology of interpenetrating network structure and fluorocarbon coating, applied in the direction of coating, can solve the problems of poor solubility of fluoropolymer and difficult preparation method, and achieve the effects of strong paintability, convenient construction and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

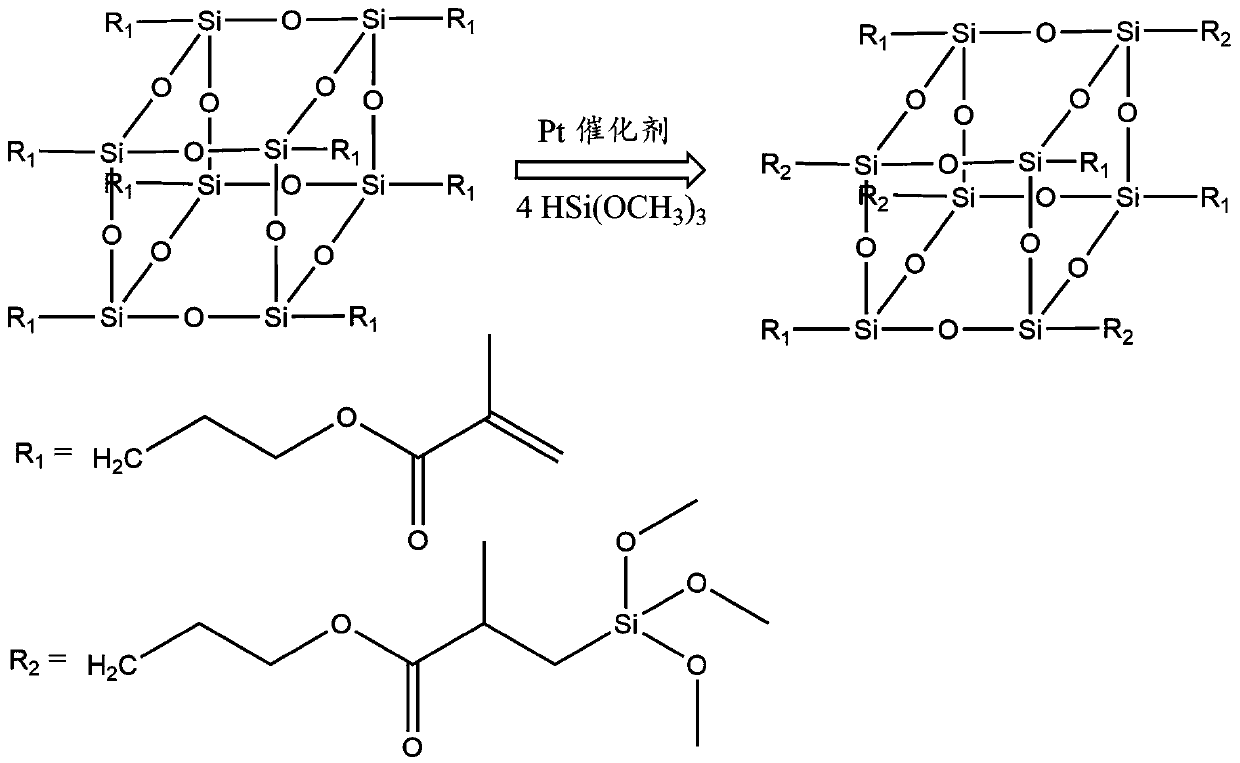

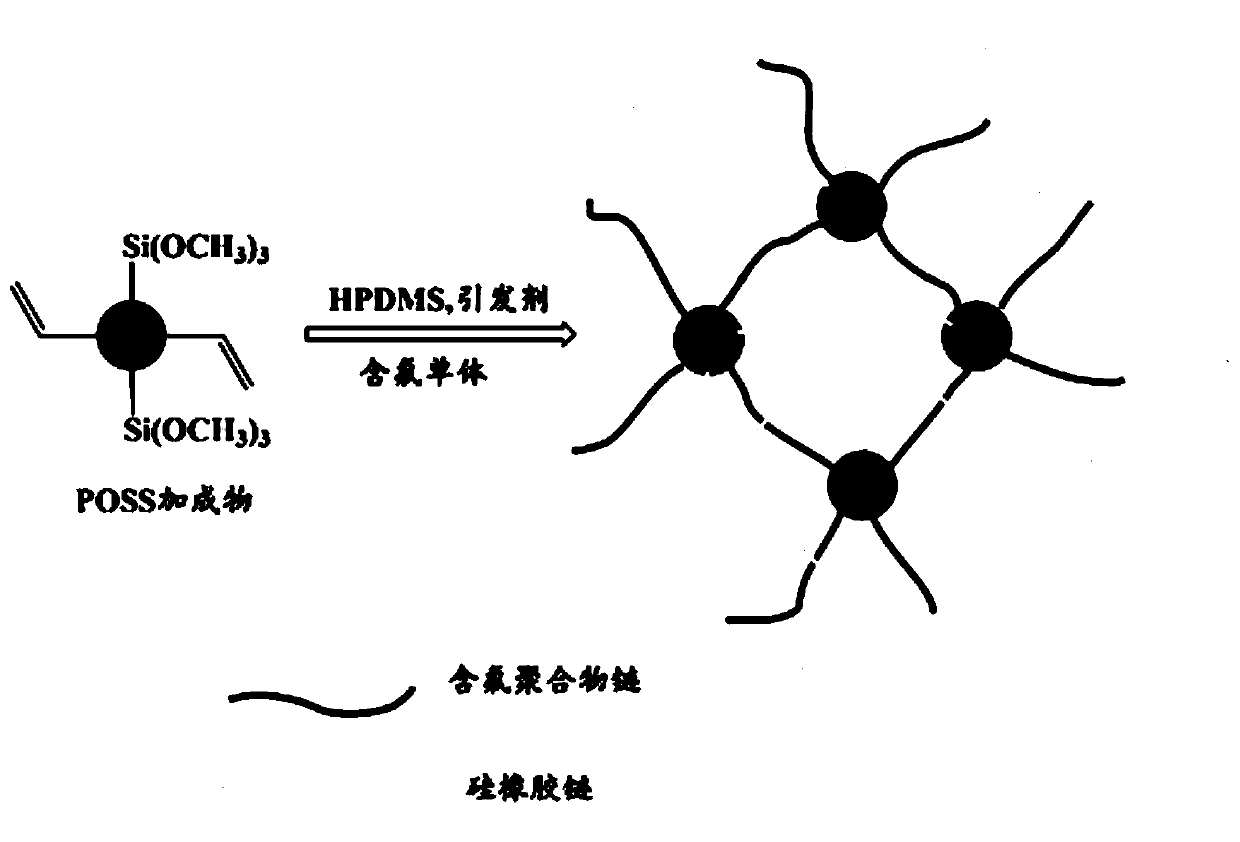

[0031] A kind of interpenetrating network structure polymer of silicone rubber-fluorocarbon coating, it is by the addition of methacryloxypropyl cage type polysilsesquioxane (being methacryloxypropyl POSS) The compound forms an interpenetrating network structure with silicone rubber and fluoropolymer, and its structural schematic is shown in Formula 1.

[0032] The preparation method of the interpenetrating network structure polymer of the above-mentioned silicone rubber-fluorocarbon coating is: add 2 g of methacryloxypropyl POSS adducts to 40 g of solvent tetrahydrofuran, and then add 40 g of hexafluorobutyl acrylate, 17 g of molecular weight 5000 hydroxyl-terminated polydimethylsiloxane, 1g initiator benzoyl peroxide, after stirring evenly, reflux at 80°C for 5 hours to obtain polymer interpenetrating network structure solution, evaporate most of the solvent and dry naturally to obtain silicon Interpenetrating network polymer of rubber-fluorocarbon coatings.

Embodiment 2

[0034] A kind of interpenetrating network structure polymer of silicone rubber-fluorocarbon coating, it is by the addition of methacryloxypropyl cage type polysilsesquioxane (being methacryloxypropyl POSS) The compound forms an interpenetrating network structure with silicone rubber and fluoropolymer, and its structural schematic is shown in Formula 1.

[0035] The preparation method of the interpenetrating network structure polymer of the above-mentioned silicone rubber-fluorocarbon coating is: add 5 g of methacryloxypropyl POSS adduct into 40 g of solvent n-heptane, and then add 5 g of hexafluorobutyl methacrylate Esters, 49.9g of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 100,000, 0.1g of initiator azobisisobutyronitrile, stirred evenly, and refluxed at 90°C for 2 hours to obtain a polymer interpenetrating network solution, evaporated After removing most of the solvent and drying naturally, the interpenetrating network structure polymer of silicone ...

Embodiment 3

[0037] A kind of interpenetrating network structure polymer of silicone rubber-fluorocarbon coating, it is by the addition of methacryloxypropyl cage type polysilsesquioxane (being methacryloxypropyl POSS) The compound forms an interpenetrating network structure with silicone rubber and fluoropolymer, and its structural schematic is shown in Formula 1.

[0038] The preparation method of the interpenetrating network structure polymer of the above-mentioned silicone rubber-fluorocarbon coating is: add 2 g of methacryloxypropyl POSS adducts in 40 g of solvent toluene, and then add 20 g of dodecafluoroheptyl methacrylate , 37.5g of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 50,000, 0.5g of initiator azobisisobutyronitrile, after stirring evenly, reflux at 70°C for 6h to obtain a polymer interpenetrating network structure solution, and evaporate most of the The interpenetrating network structure polymer of the silicone rubber-fluorocarbon coating is obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com