Ozone oxidation catalyst for degradation of organic wastewater and preparation method thereof

A technology for ozone oxidation and organic wastewater, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. The problem of excessive consumption can achieve the effect of saving operating costs, reducing production costs and good practical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

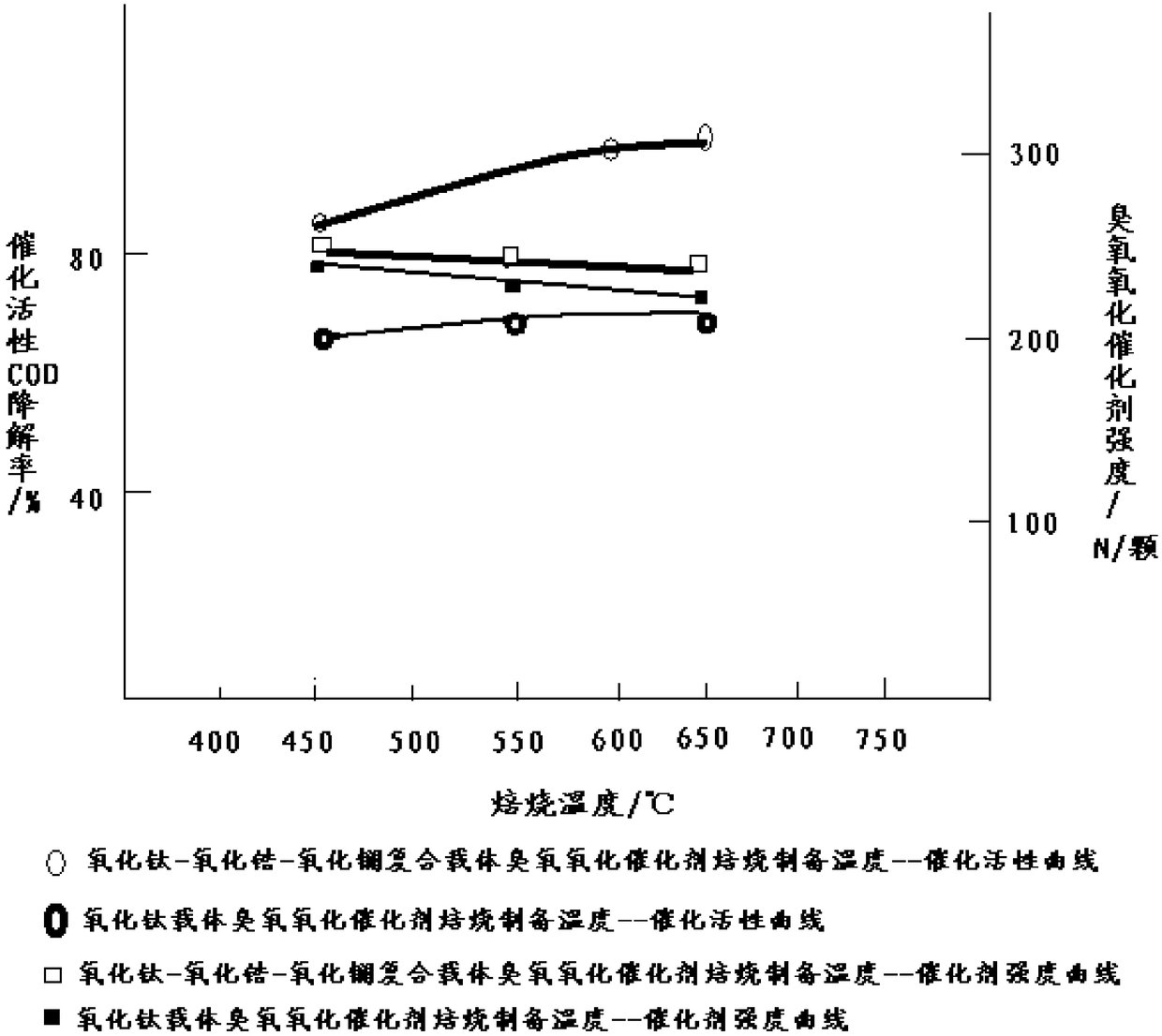

Image

Examples

Embodiment 1

[0024] Prepare organic wastewater degradation ozone oxidation catalyst according to the following steps:

[0025] 1) Preparation of the composite carrier: the target composition of the composite carrier in terms of mass percentage is: 83% titanium oxide; 13% zirconium oxide; 4% lanthanum oxide; weigh the titanium oxide powder and the zirconium oxide powder according to the above ratio and mix them thoroughly Afterwards, microwave heating to a temperature of 90°C, impregnating a lanthanum nitrate solution with a mass percent concentration of 18% for 24 hours, staleing for another 24 hours, drying at a temperature of 110°C until the moisture content is lower than 1 wt%, and then roasting at 500°C After 4 hours, the particle size of the ball milled powder is less than 20 microns to prepare a composite carrier powder;

[0026] 2) Preparation of active powder: using microwave heating and impregnation method, the composite carrier prepared in step 1) is immersed in the impregnation ...

Embodiment 2

[0029] Prepare organic wastewater degradation ozone oxidation catalyst according to the following steps:

[0030] 1) Preparation of the composite carrier: the target composition of the composite carrier in terms of mass percentage is: 84% titanium oxide; 13% zirconium oxide; 3% lanthanum oxide; weigh the titanium oxide powder and the zirconium oxide powder according to the above ratio and mix them thoroughly Afterwards, microwave heating to a temperature of 90°C, impregnating a lanthanum nitrate solution with a mass percent concentration of 18% for 24 hours, staleing for another 24 hours, drying at a temperature of 110°C until the moisture content is lower than 1 wt%, and then roasting at 500°C After 4 hours, the particle size of the ball milled powder is less than 20 microns to prepare a composite carrier powder;

[0031] 2) Preparation of active powder: using microwave heating and impregnation method, the composite carrier prepared in step 1) is immersed in the impregnation ...

Embodiment 3

[0034] Prepare organic wastewater degradation ozone oxidation catalyst according to the following steps:

[0035]1) Preparation of the composite carrier: the target composition of the composite carrier in terms of mass percentage is: 83% titanium oxide; 13% zirconium oxide; 4% lanthanum oxide; weigh the titanium oxide powder and the zirconium oxide powder according to the above ratio and mix them thoroughly Afterwards, microwave heating to a temperature of 90°C, impregnating a lanthanum nitrate solution with a mass percent concentration of 18% for 24 hours, staleing for another 24 hours, drying at a temperature of 110°C until the moisture content is lower than 1 wt%, and then roasting at 500°C After 4 hours, the particle size of the ball milled powder is less than 20 microns to prepare a composite carrier powder;

[0036] 2) Preparation of active powder: using microwave heating and impregnation method, the composite carrier prepared in step 1) is immersed in the impregnation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com