Micro-powder for preparing neodymium-iron-boron permanent magnet material, target type air-current powder milling method and milled powder

A permanent magnet material, NdFeB technology, used in magnetic materials, electrical components, magnetic objects, etc., can solve the problems of high price of helium, high specific gravity of ultrafine powder, slow powder extraction rate, etc., to achieve high consistency, The effect of low particle attachment rate and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

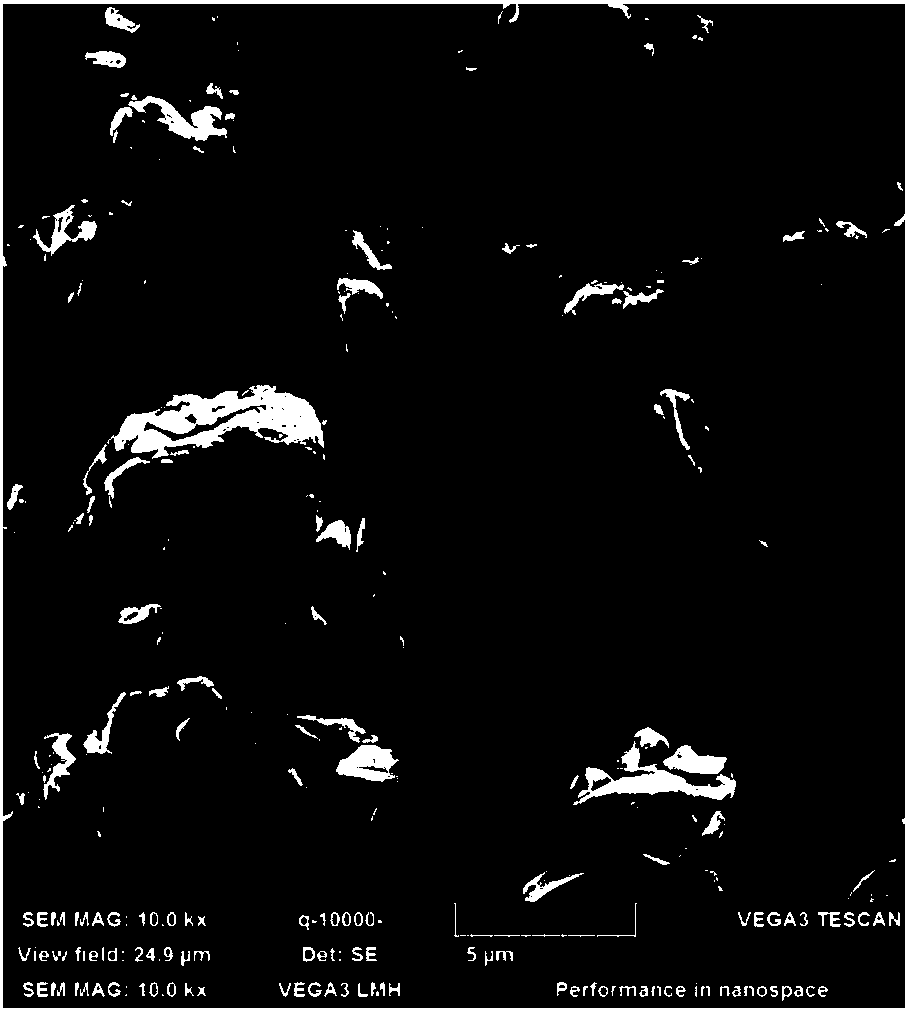

[0049] The Nd-Fe-B alloy ingot is prepared into a strip sheet with an average thickness of 0.32mm by the quick-setting thin sheet method, and its composition is Nd 31 Dy 1 co 1 Cu 0.1 Zr 0.08 Ga 0.12 Al 0.1 Nb 0.3 Fe bal B 0.97 (wt.%, for mass percentage). The NdFeB quick-setting thin strips are crushed by the HD method to obtain coarse powder. Add 0.05wt% lubricant to the coarse powder and mix through a powder mixer. The mixed powder is ultrafinely crushed by a target jet mill. The grinding pressure is 0.6MPa, the jet mill nozzle and the target material are all made of silicon nitride Laval nozzle, the formula of the target diameter, the side nozzle diameter, and the distance between the target and the side nozzle is m=3, and the jet air velocity is 400m / s. At the same time, the ceramic classifying wheel is selected, and in the formula of its diameter and the target diameter, p=4. The final powder output is divided into two parts. The qualified micro powder accoun...

Embodiment 2

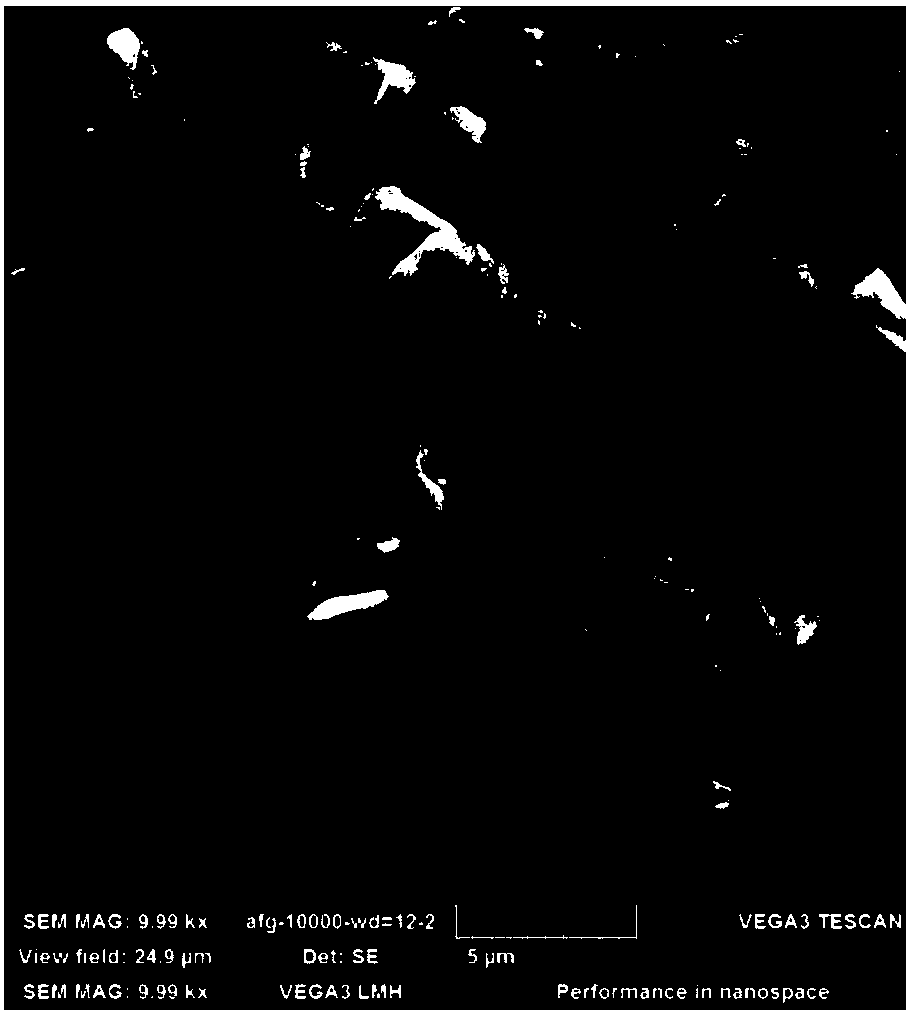

[0057] The NdFeB alloy ingot is prepared into a strip sheet with an average thickness of 0.1mm by the quick-setting thin sheet method, and its composition is (PrNd) 30.8 co 0.5 Cu 0.06 Zr 0.10 Ga 0.10 Al 0.3 Nb 0.3 Fe bal B 0.94 (wt.%, for mass percentage). The NdFeB quick-setting thin strips are crushed by the HD method to obtain coarse powder. Add 0.5wt% lubricant to the coarse powder and mix through a powder mixer. The mixed powder is ultrafinely crushed by a target jet mill. The grinding pressure is 0.3MPa, the jet mill nozzle and the target material are all made of silicon nitride Laval nozzle, the formula of the target diameter, the side nozzle diameter, and the distance between the target and the side nozzle is m=2, and the jet air velocity is 520m / s. At the same time, the ceramic grading wheel is selected, and in the formula of its diameter and the diameter of the bull's-eye, p=3.5. The final powder output is divided into two parts. The qualified micro powde...

Embodiment 3

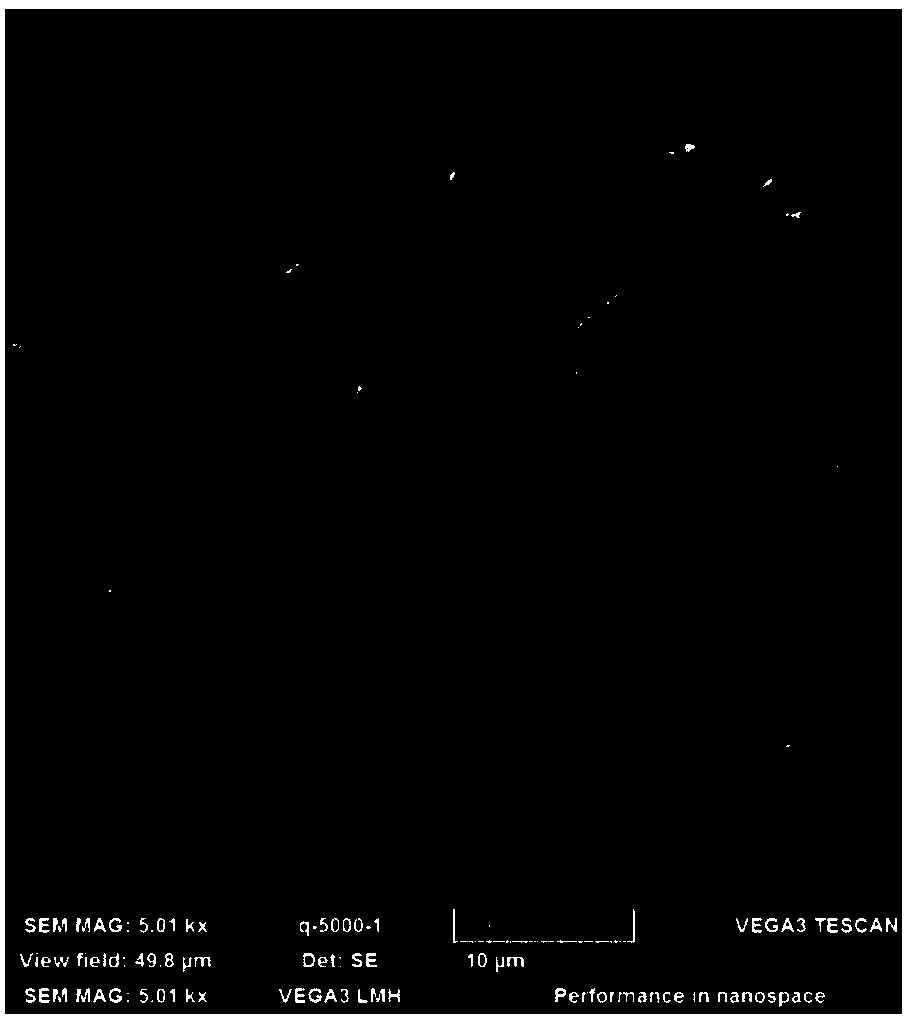

[0065] The NdFeB alloy ingot is prepared into a strip sheet with an average thickness of 0.4mm by the quick-setting thin sheet method, and its composition is (PrNd) 26 Dy 5 co 1.3 Cu 0.15 Zr 0.08 Ga 0.16 Al 0.25 Fe bal B 0.97 (wt.%, for mass percentage). The NdFeB quick-setting thin strips are crushed by the HD method to obtain coarse powder. Add 0.3wt% lubricant to the coarse powder and mix through a powder mixer. The mixed powder is ultrafinely crushed by a target jet mill. The grinding pressure is 0.8MPa, the jet mill nozzle and the target material are all made of silicon nitride Laval nozzle, the formula of the target diameter, the side nozzle diameter, and the distance between the target and the side nozzle is m=5, and the jet air velocity is 320m / s. At the same time, the ceramic grading wheel is selected, and in the formula of its diameter and the target diameter, p=4.5. The final powder output is divided into two parts. The qualified micro powder accounts for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com