Mining device and method for continuously exploiting marine natural gas hydrates

A technology for natural gas and hydrate, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc. It can solve the problems of large heat loss, decomposition of natural gas hydrate, and decrease of effective formation stress, and reduce the footprint , the effect of preventing geological disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to show the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention. In order to avoid obscuring the essence of the present invention, known methods and processes are not described in detail.

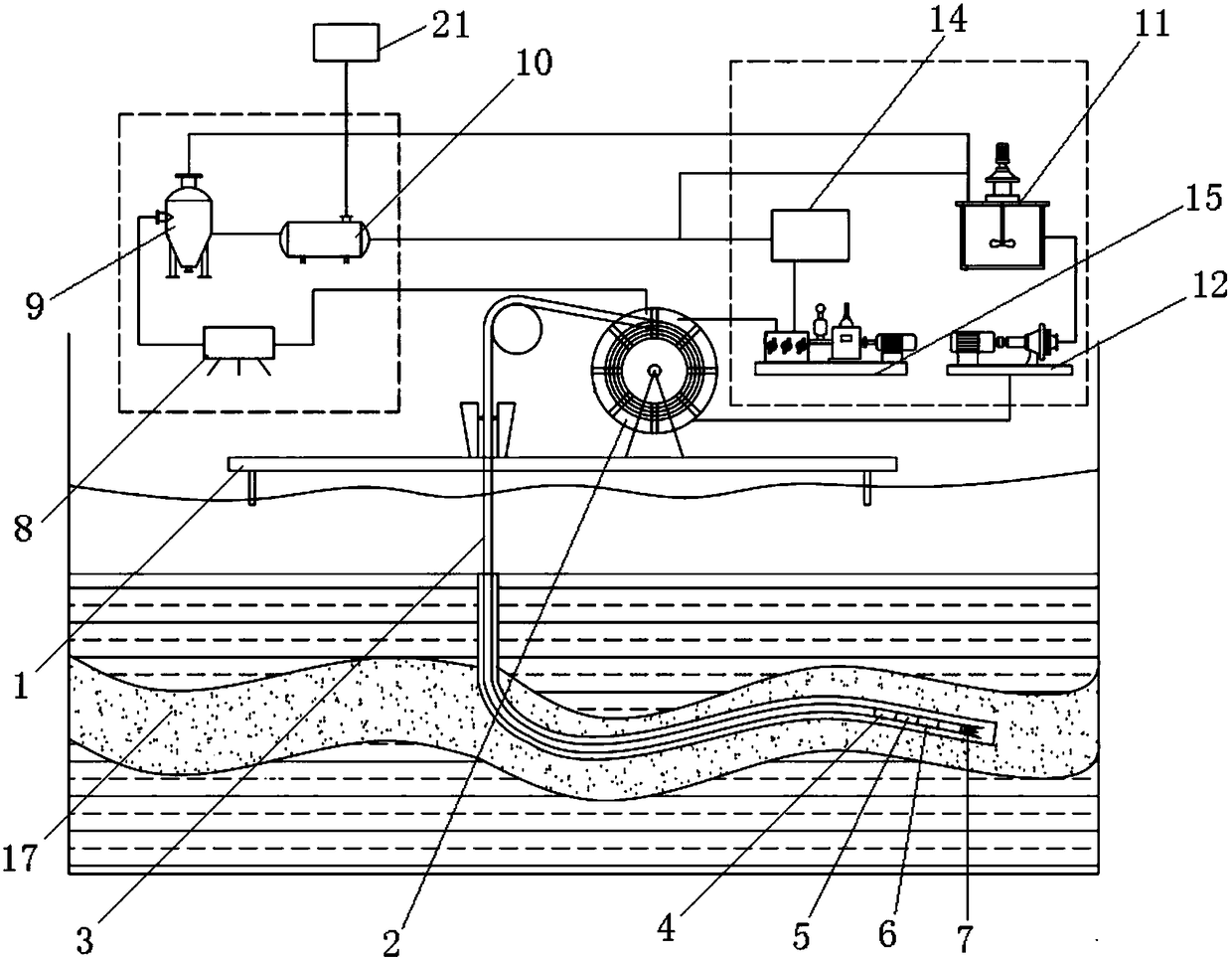

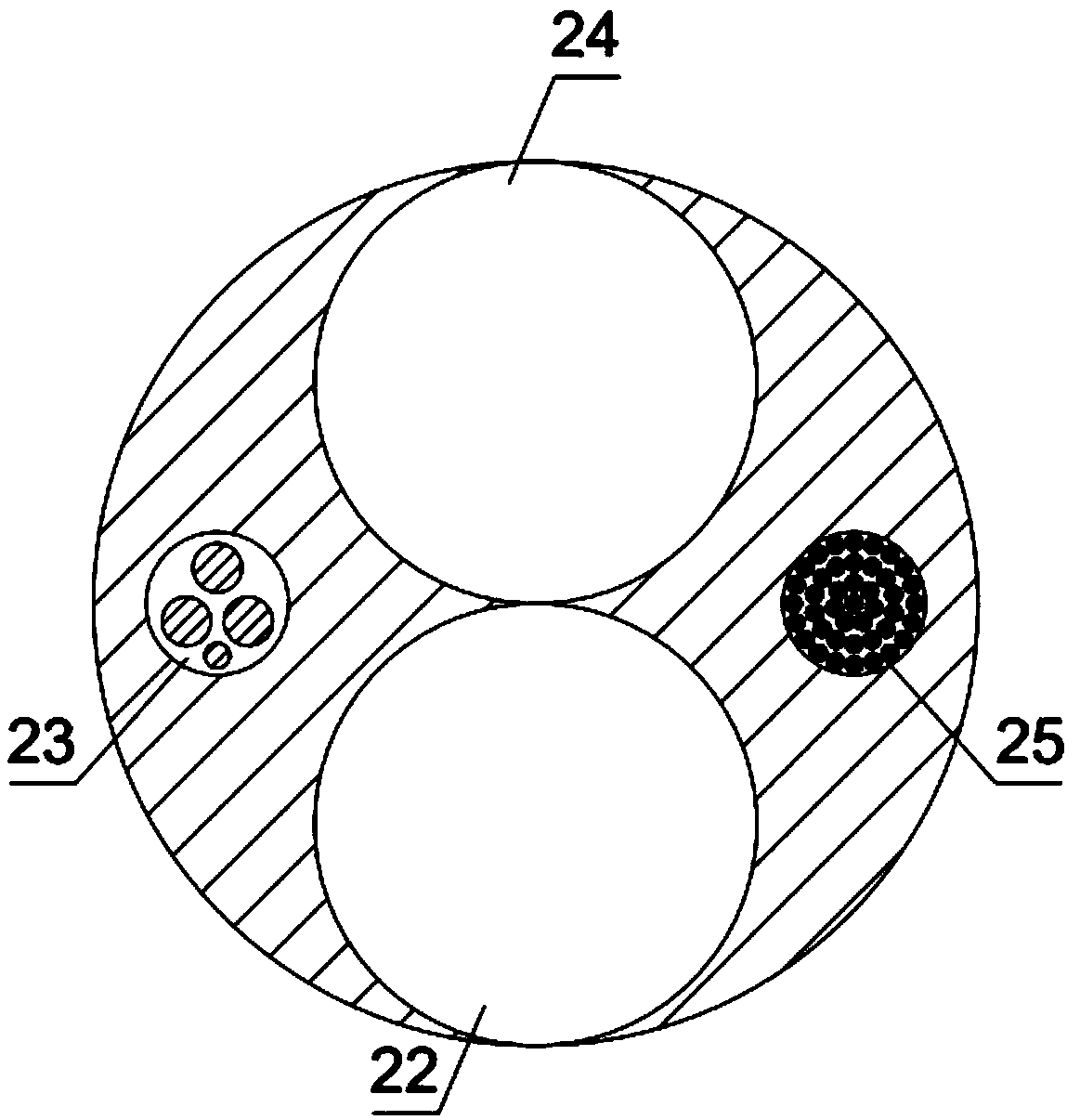

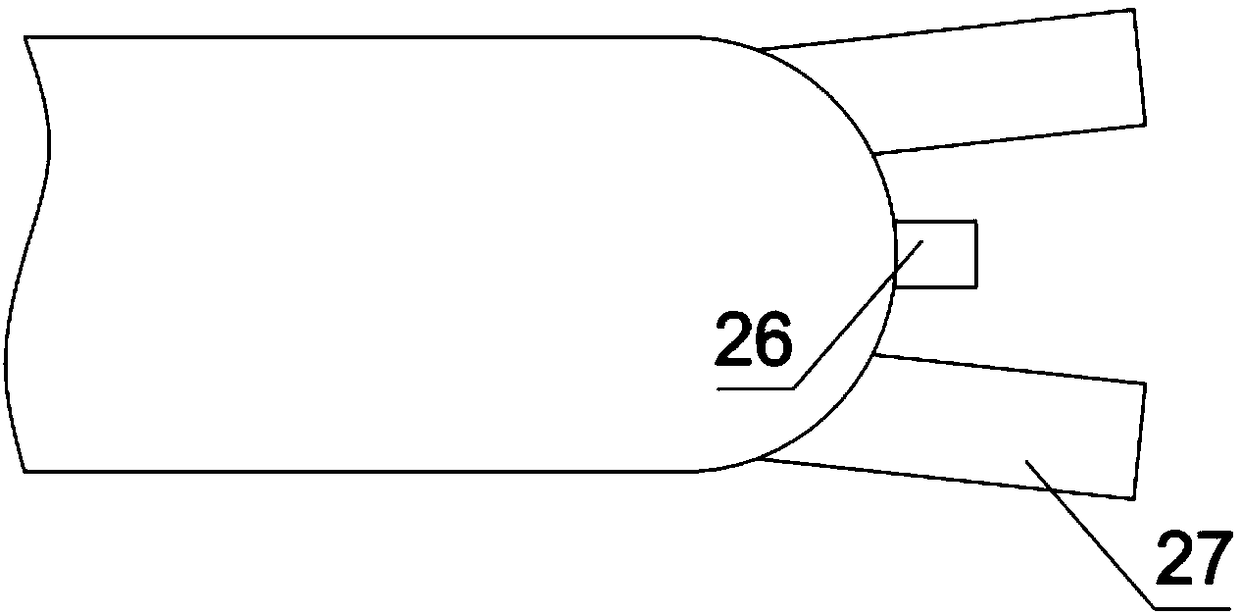

[0029] Such as figure 1 , figure 2 and image 3 As shown, a production device for continuous exploitation of marine natural gas hydrates, including offshore auxiliary devices, double-channel coiled tubing drilling devices, decomposition and separation devices and waste backfill devices,

[0030] Among them, the offshore auxiliary device includes power equipment and control equipment, and the control equipment is connected with the power equipment; it provides power and related...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com