Nuclear shell structure nano-metal interconnection process

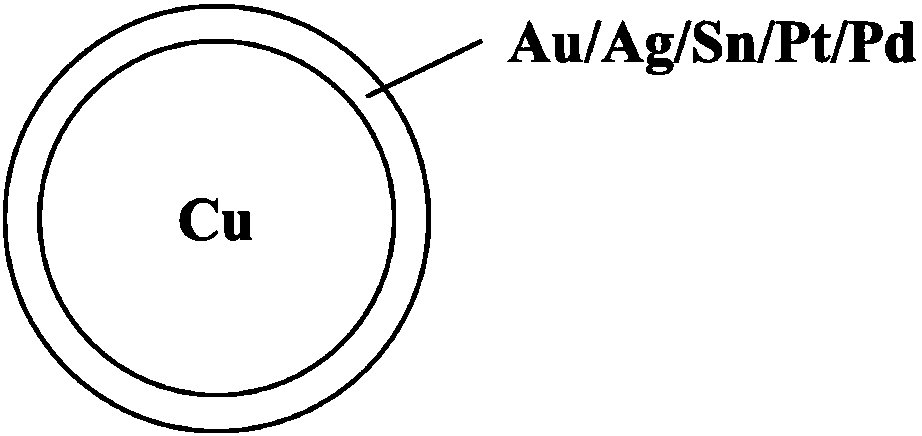

A core-shell structure and nano-metal technology, applied in metal processing equipment, nanotechnology, nanotechnology, etc., can solve problems such as high interconnection temperature, high energy environment, device damage, etc., achieve compact morphology and reduce interconnection temperature and interconnection conditions, the effect of improving oxidation resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the core-shell structured nanoparticle interconnection material provided by the present invention includes:

[0036] a) The nano copper particles are mixed with the protective agent to obtain a nano copper solution;

[0037] b) The shell precursor and the nano copper solution are mixed, reacted, centrifuged and washed to obtain core-shell bimetallic nanoparticles;

[0038] c) Dispersing the core-shell bimetallic nanoparticles in a solvent and degassing to obtain a core-shell structured nanoparticle interconnection material.

[0039] The preparation method of the core-shell structure nano particle interconnection material provided by the present invention firstly mixes the nano copper particles and the protective agent to obtain a nano copper solution. The preferred specific is:

[0040] The nano copper particles and the protective agent are dispersed in a solvent, and magnetically stirred at room temperature to form a uniformly dispersed nano copper sol...

Embodiment 1

[0077] Add nano-copper particles with a size of 20nm and protective agent polyacrylamide in ethylene glycol solvent, wherein the molar ratio of protective agent to nano-copper particles is 2:1; magnetically stir at room temperature for 30 minutes to form uniformly dispersed nano-copper Solution; Add chloroauric acid to the nano-copper solution, where the molar ratio of chloroauric acid to nano-copper particles is 0.01:1, and the mixed solution is stirred and reacted at room temperature for 90 minutes, and deionized water and water are used at 5000r / min Anhydrous ethanol was centrifuged and washed 4 times each to obtain bimetallic core-shell structured nanoparticles; the core-shell nanoparticles were dispersed in a solvent of diethylene glycol and ethylene glycol butyl ether, and subjected to a vacuum degassing mixture treatment at 2000r / min After 5 minutes, the core-shell nanoparticle interconnecting material is obtained, and the mass ratio of the core-shell nanoparticle powder ...

Embodiment 2

[0080] Add nano-copper particles with a size of 300nm and protective agent polyvinylpyrrolidone into the glycerol solvent, wherein the molar ratio of the protective agent to the nano-copper particles is 5:1; magnetically stir at room temperature for 30 minutes to form uniformly dispersed nano-copper Solution: Add palladium acetate to the nano-copper solution, where the molar ratio of palladium acetate to nano-copper particles is 0.005:1, and the mixed solution is stirred and reacted at room temperature for 120 minutes, and deionized water and anhydrous at 7000r / min Ethanol was centrifuged and washed 4 times each to obtain bimetallic core-shell structured nanoparticles. The core-shell nanoparticles were dispersed in a solvent of ethylene glycol and ethylene glycol methyl ether, and subjected to a vacuum degassing mixing treatment of 3000 r / min for 5 minutes to obtain a core-shell nanoparticle interconnecting material. The core-shell nanoparticle powder accounted for the interconn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com