Transition metal complex nano-catalyst and preparation method and application thereof

A transition metal, nanocomposite technology, applied in physical/chemical process catalysts, chemical instruments and methods, non-metallic elements, etc., can solve problems such as weak functionality, achieve simple preparation methods, high yields, and improve uniform dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of Metal Organic Framework MOF-74-M:

[0036] MOF-74-Ni: Dissolve 0.478g of 2,5-dihydroxyterephthalic acid and 2.378g of nickel nitrate hexahydrate in ethanol (70ml), water (70ml), N, in a mixed solution of N-dimethylformamide (70ml) until it was completely dissolved. The dissolved solution was transferred to a glass bottle, placed in an oven at 110°C and kept warm for 24 hours. The precipitate produced by the reaction was removed, washed with methanol, soaked for 4 hours, and the supernatant was poured out and separated, and repeated 4 times. Then place the precipitate in the bottle in an oven at 110° C. and keep it warm for 3 hours to dry. Finally, the dried powder was vacuum-treated at 180°C for 2 hours and cooled naturally, and the powder was collected to obtain MOF-74-Ni.

[0037] MOF-74-Co: Dissolve 0.478g of 2,5-dihydroxyterephthalic acid and 2.377g of cobalt nitrate hexahydrate in ethanol (70ml), water (70ml), N, in a mixed solution of N-dimethyl...

Embodiment 1

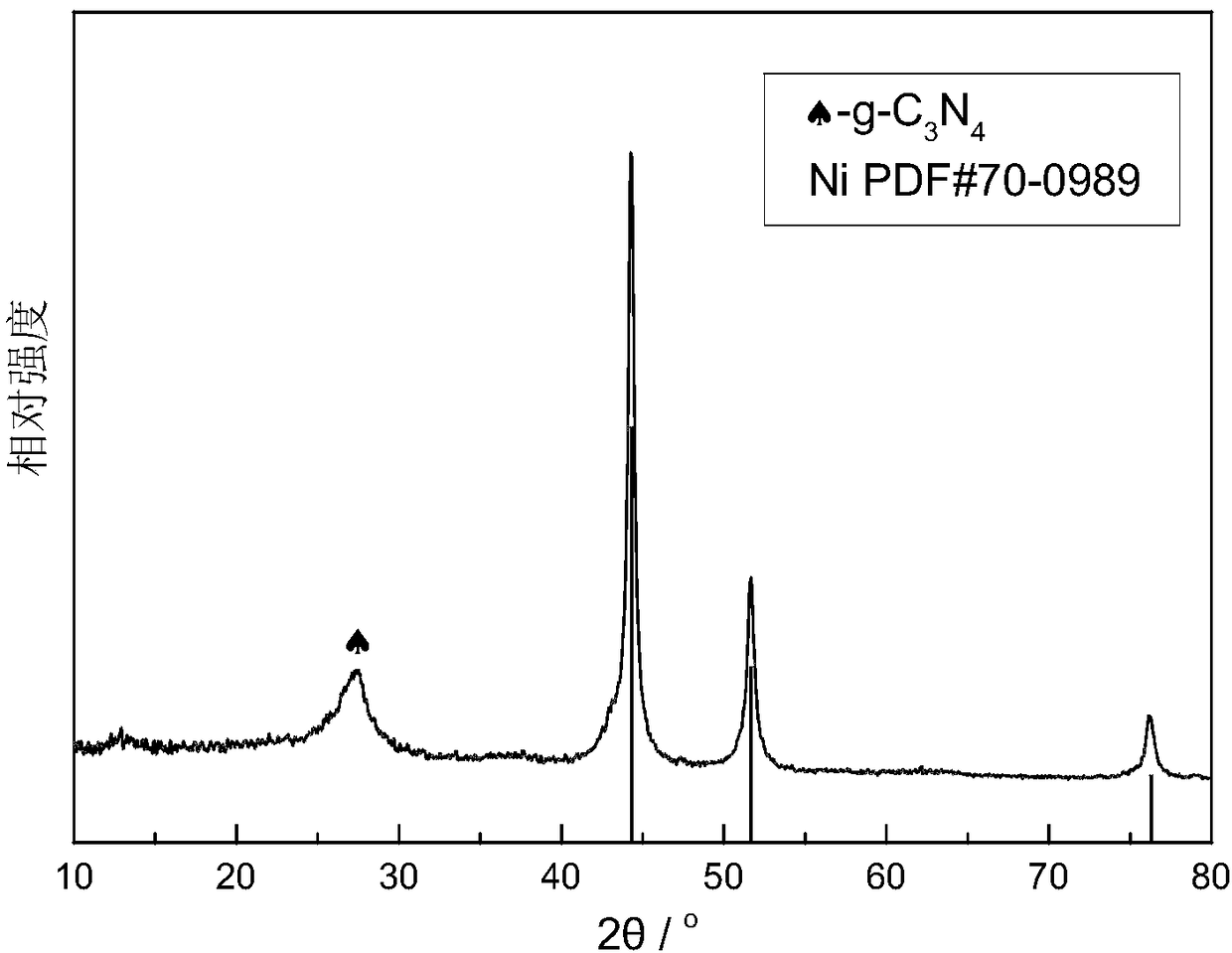

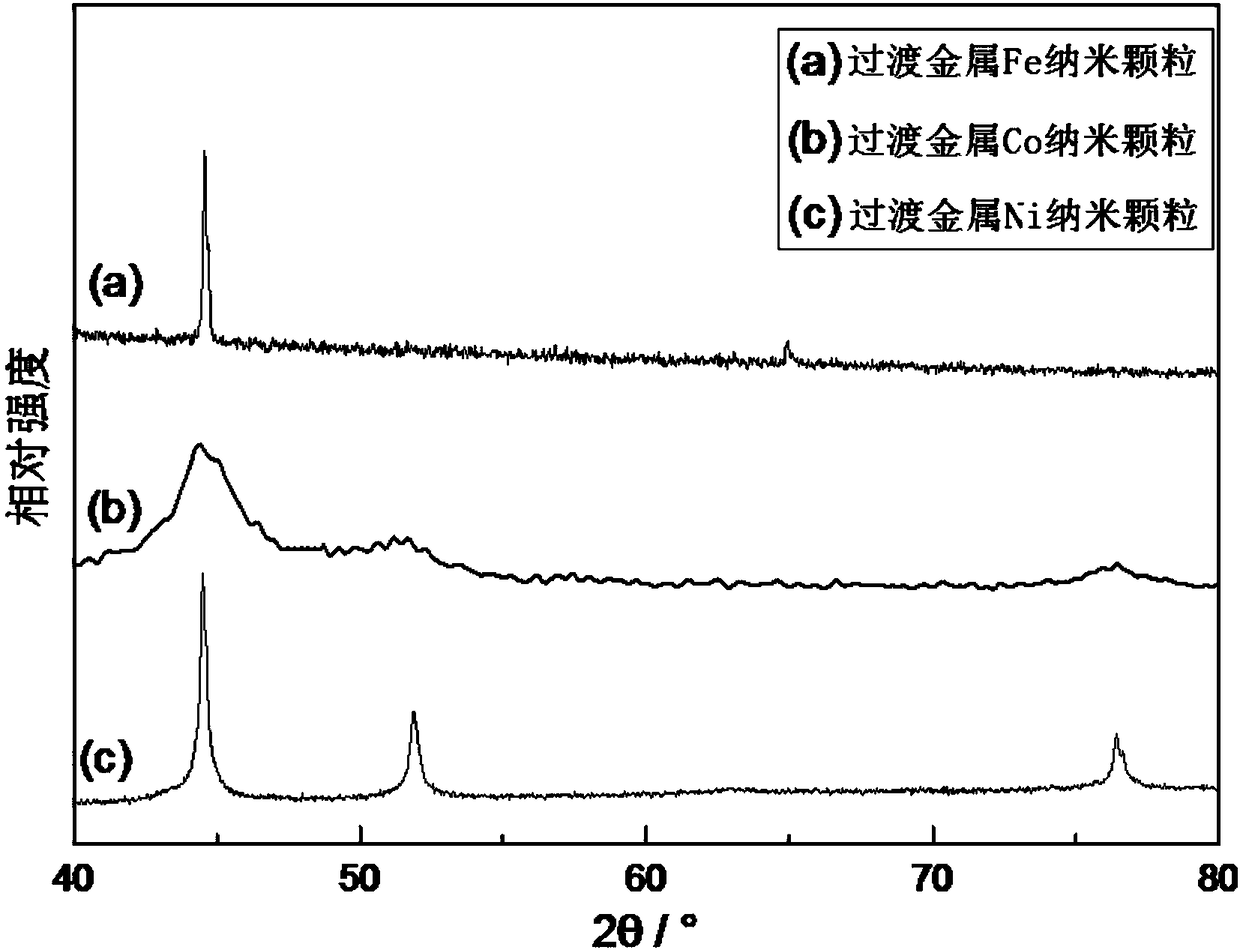

[0040] (1) Using urea as a precursor, calcining at 550°C for 0.5 hours to prepare lamellar g-C 3 N 4 ;

[0041] (2) The metal-organic framework MOF-74-Ni was carbonized at a high temperature of 700°C under argon gas, and the carbonization time was 0.5 hours, and carbon-supported transition metal Ni nanoparticles were synthesized in situ;

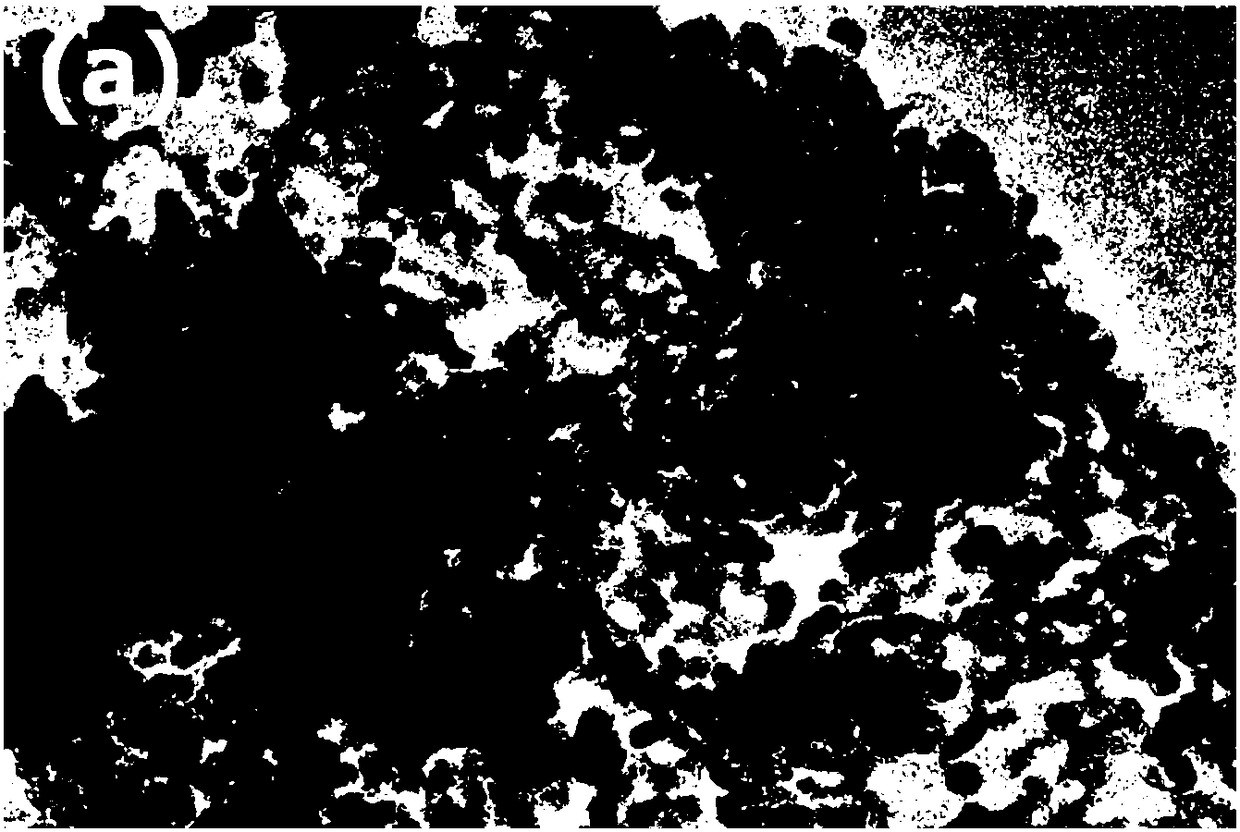

[0042] (3) At an ambient temperature of 25°C, 1g g-C 3 N 4 and 1 g of transition metal Ni nanoparticles were added into 10 mL of absolute ethanol, and stirred at a constant speed of 400 r / min for 1 hour to form a uniform suspension.

[0043] (4) The homogeneously stirred suspension was subjected to ultrasonic treatment for 0.5 h, and then vacuum-dried at 80° C. for 4 hours until the ethanol was completely volatilized to obtain a black viscous substance.

[0044] (5) Continue to heat up the black viscous substance to 150°C and keep it warm for 2 hours to obtain lamellar g-C 3 N 4 The Ni nanoparticle composite catalyst loaded with transi...

Embodiment 2

[0047] (1) Using urea as a precursor, calcining at 550°C for 0.5 hours to prepare lamellar g-C 3 N 4 ;

[0048] (2) The metal-organic framework MOF-74-Co was carbonized at a high temperature of 700°C under nitrogen, and the carbonization time was 0.5 hours, and carbon-supported transition metal Co nanoparticles were synthesized in situ;

[0049] (3) At an ambient temperature of 25°C, 1g g-C 3 N 4 and 1 g of transition metal Co nanoparticles were added to 10 mL of absolute ethanol, and stirred at a constant speed of 400 r / min for 1 hour to form a uniform suspension.

[0050] (4) The homogeneously stirred suspension was subjected to ultrasonic treatment for 0.5 h, and then vacuum-dried at 80° C. for 4 hours until the ethanol was completely volatilized to obtain a black viscous substance.

[0051] (5) Continue to heat up the black viscous substance to 150°C and keep it warm for 2 hours to obtain lamellar g-C 3 N 4 The transition metal Co nanoparticle composite catalyst supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com