a mgmn 2 o 4 Nanofiber electrode material and preparation method thereof

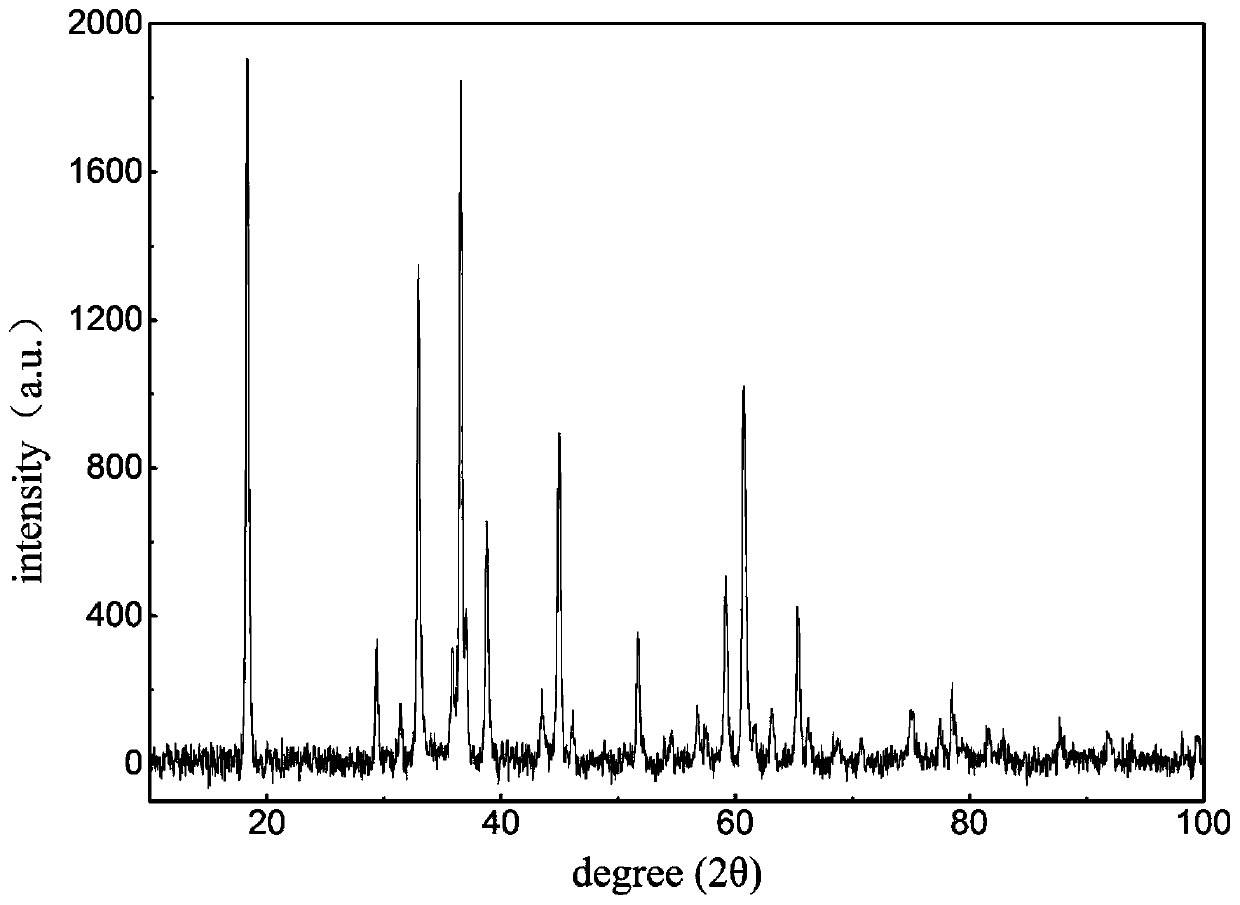

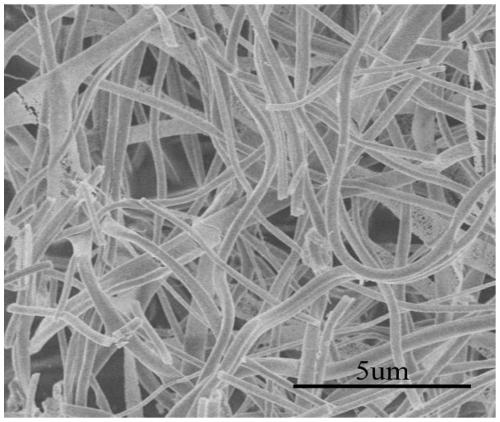

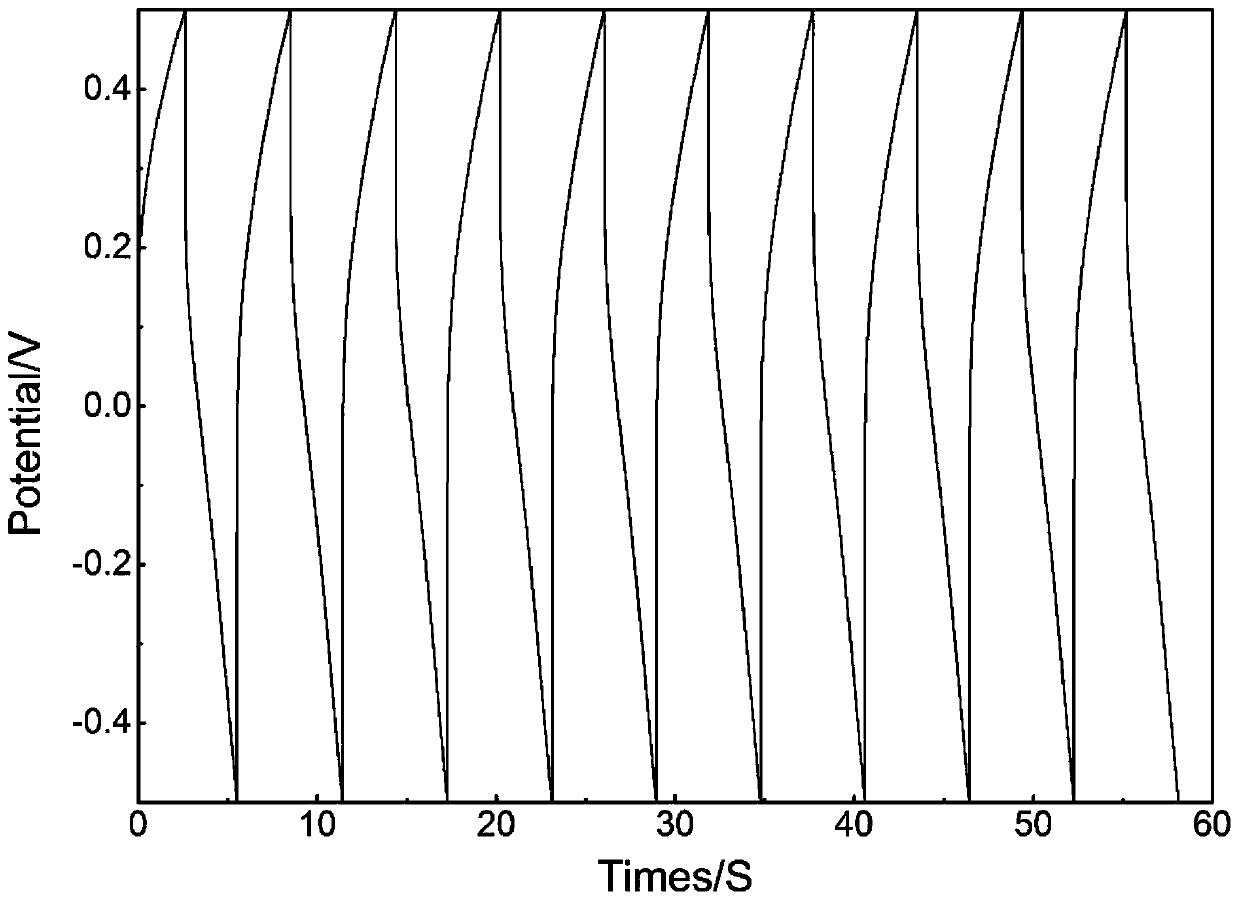

A nanofiber and electrode material technology, applied in the field of MgMn2O4 nanofiber electrode material and its preparation, can solve the problems of short cycle life and low energy storage density of ion batteries, and achieve long cycle life, strong crystal structure stability, and crystallinity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: a kind of MgMn of the present embodiment 2 o 4 The preparation method steps of nanofiber electrode material are as follows:

[0037] 1. Weigh 0.38g magnesium nitrate, 0.75g manganese nitrate and 1.67g ethylene glycol respectively, first fully dissolve magnesium nitrate in 5ml deionized water at room temperature to make magnesium nitrate solution, then fully dissolve manganese nitrate at room temperature Finally, add ethylene glycol to the above solution and stir at a speed of 400-600r / min for 20min to obtain salt solution A.

[0038] 2. Add a total amount of 1.2-1.8g of PVP in batches to 15mL of absolute ethanol, and fully stir at room temperature at a speed of 400-600r / min for 3h to obtain polymer solution B.

[0039] 3. At a stirring speed of 300-450r / min, slowly add the salt solution A to the polymer solution B dropwise, after all the dropping is completed, increase the stirring speed to 400-600r / min and continue stirring for 10-15h to obtain MgMn 2...

Embodiment 2

[0047] Embodiment 2: a kind of MgMn of the present embodiment 2 o 4 The preparation method steps of nanofiber electrode material are as follows:

[0048] 1. Weigh 0.38g magnesium nitrate, 0.75g manganese nitrate and 1.67g ethylene glycol respectively, first fully dissolve magnesium nitrate in 5ml deionized water at room temperature to make magnesium nitrate solution, then fully dissolve manganese nitrate at room temperature Finally, add ethylene glycol to the above solution and stir at 500r / min for 20min to obtain salt solution A.

[0049] 2. Add a total amount of 1.5 g of PVP in batches to 15 mL of absolute ethanol, and stir thoroughly at room temperature at a speed of 500 r / min for 3 h to obtain polymer solution B.

[0050] 3. Slowly add the salt solution A to the polymer solution B at a stirring speed of 350r / min. After all the addition is completed, increase the stirring speed to 500r / min and continue stirring for 12 hours to obtain MgMn 2 o 4 Spinning precursor soluti...

Embodiment 3

[0059] Embodiment 3: a kind of MgMn of this embodiment 2 o 4 The preparation method steps of nanofiber electrode material are as follows:

[0060] 1. Weigh 0.38g magnesium nitrate, 0.75g manganese nitrate and 1.67g ethylene glycol respectively, first fully dissolve magnesium nitrate in 5ml deionized water at room temperature to make magnesium nitrate solution, then fully dissolve manganese nitrate at room temperature Finally, add ethylene glycol to the above solution and stir at 550r / min for 20min to obtain salt solution A.

[0061] 2. Add a total amount of 1.6 g of PVP in batches to 15 mL of absolute ethanol, and stir at room temperature at a speed of 550 r / min for 3 h to obtain polymer solution B.

[0062] 3. Slowly add the salt solution A to the polymer solution B at a stirring speed of 400r / min. After all the addition is completed, increase the stirring speed to 550r / min and continue stirring for 11 hours to obtain MgMn 2 o 4 Spinning precursor solution C.

[0063] 4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com