Preparation method of NdFeB powder

A NdFeB powder technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problem of increasing the number of collisions between coarse particles and fine particles, increasing the unevenness of powder particles, and accelerating airflow Slowness and other problems, to achieve the effect of uniform distribution, uniform distribution, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a preparation method of NdFeB powder, comprising:

[0020] Take the coarse powder obtained by crushing the NdFeB alloy cast sheet through hydrogen absorption; the method of hydrogen absorption crushing here is a conventional method in the art;

[0021] Crush the coarse powder into an intermediate powder with an average particle size of 35-65 μm; there is no limit to what kind of pulverizer, as long as the coarse powder is crushed to 35-65 μm;

[0022] The intermediate powder is mixed with 0.03-0.1% zinc stearate by weight of the intermediate powder, and then crushed to a fine powder with an average particle size of 3-5 μm and a particle size distribution D90 / D10 of 4.2-5 with a jet mill. On the one hand, zinc stearate acts as a lubricant, on the other hand, it increases the distance between powder particles, reduces the van der Waals force between particles, prevents agglomeration, and improves the crushing efficiency of the jet mill. The obtaine...

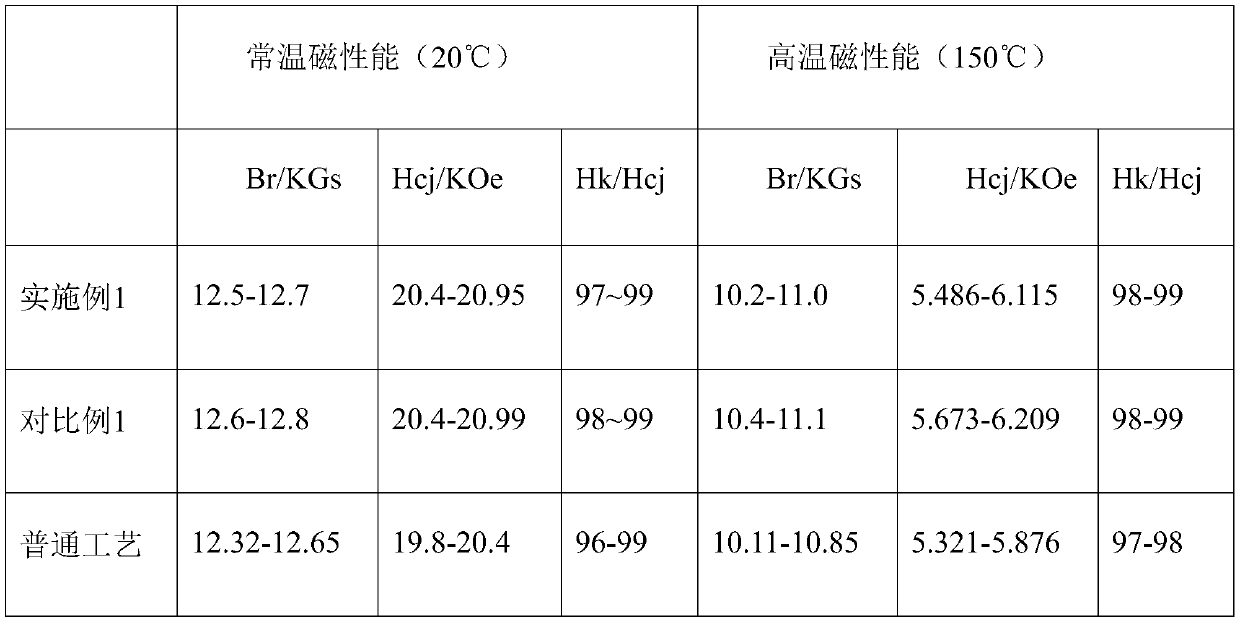

Embodiment 1

[0029] The verification is done with 35SH sintered NdFeB materials, and 600Kg of raw materials are prepared. Among them, the iron rods must be derusted, and the rare earth materials must be oil-free, moisture-free, and rust-free. The prepared raw materials are heated and melted by intermediate frequency induction through vacuum smelting (SC) The metal is then cast onto a rotating water-cooled cooling roller through a tundish, and finally a flake-shaped fast-quenching NdFeB alloy with a columnar crystal structure is obtained, and then hydrogen-absorbing and dehydrogenating in a hydrogen-breaking furnace to crush millimeter-sized coarse particles. The coarse powder after hydrogen crushing is added to the hammer mechanical crusher, and nitrogen gas of 0.2-0.5MPa is introduced to adjust the feeding current of the crusher. The current adjustment range is 0.1-0.35A, and the feeding weight of the crusher is controlled. The weight of the material in the mill is kept at 20-60Kg, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com