Preparation method of carbon/silicon carbide-zirconium carbide ceramic-based composite material

A technology of carbon composite materials and silicon-zirconium alloys, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problems of uneven distribution of matrix, uneven density of inner and outer layers, incomplete penetration of alloys, etc., and achieve short preparation cycle , the effect of less amount of citrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

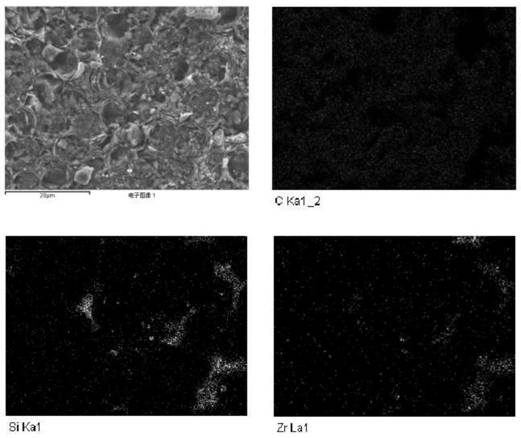

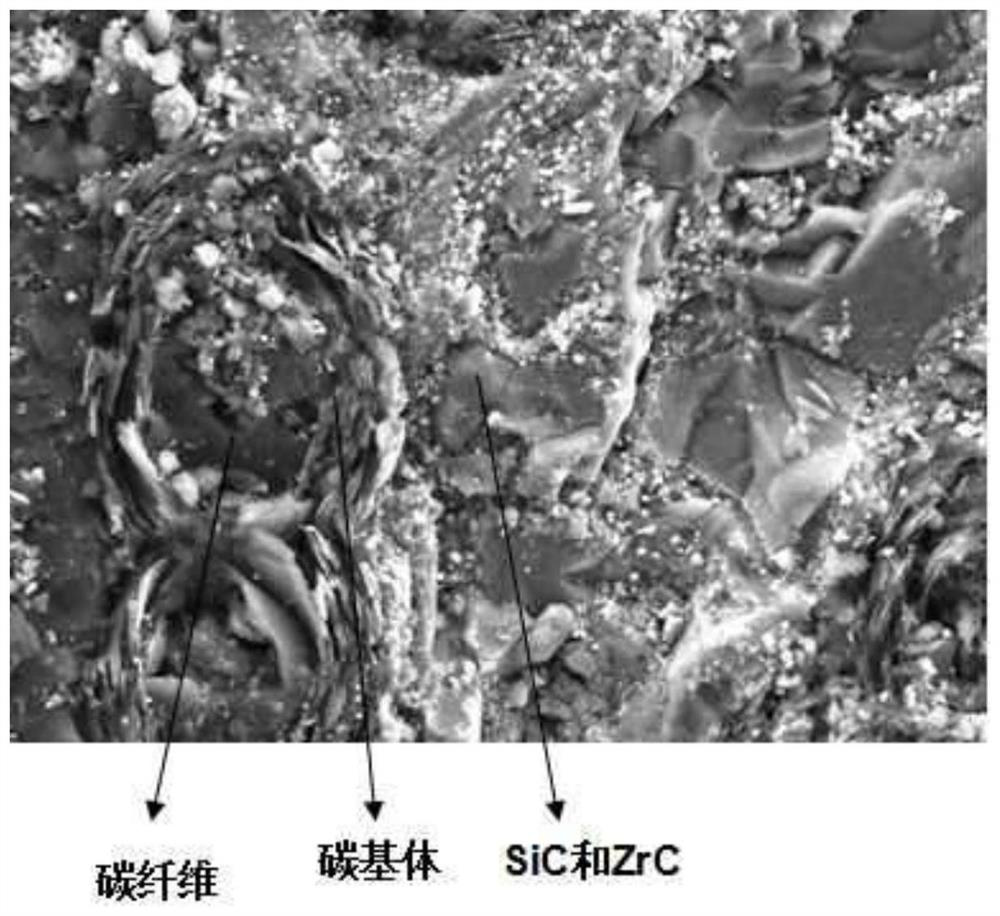

Image

Examples

preparation example Construction

[0033] The present invention provides a kind of preparation method of porous carbon / carbon composite material in the first aspect, described preparation method comprises the following steps:

[0034] (1) Provide carbon fiber prefabricated body;

[0035] (2) Using citrate as a precursor, a porous carbon matrix with pores is formed inside the carbon fiber prefabricated body by a precursor dipping and cracking method;

[0036] (3) soak the porous carbon matrix in a hydrochloric acid solution, remove the carbonate formed by sintering inside the lime by chemical reaction, and obtain a porous carbon / carbon composite material from which the carbonate is removed;

[0037] (4) drying the porous carbon / carbon composite material obtained in step (3) to obtain a dry porous carbon / carbon composite material;

[0038] (5) Repeat steps (2) to (4) at least once to obtain the porous carbon / carbon composite material.

[0039] According to some preferred embodiments, in step (1), the carbon fib...

Embodiment 1

[0066] S1. Pretreatment: Place a commercially purchased carbon fiber fiber prefabricated body (purchased from Jiangsu Tianniao Company) in a high-temperature furnace, feed nitrogen gas with a gas flow rate of 1000 sccm, raise the temperature to 1700°C, and keep the temperature constant for 10 hours to remove residual pollution on the surface things.

[0067] S2. Preparation of the porous carbon matrix: the above preform was immersed in a precursor solution prepared by sodium citrate and deionized water at a mass ratio of 1:0.5, and vacuum impregnated for 60 minutes. After taking out, the obtained material was placed in a high-temperature cracking furnace, and raised to 700° C. under the protection of nitrogen to ensure that the sodium citrate was fully cracked, and a porous carbon matrix was prepared.

[0068] S3. Introduce hydrochloric acid to remove the sodium carbonate particles formed inside: soak the porous carbon matrix in 0.1mol / L HCl solution for a reaction time of 60 ...

Embodiment 2

[0074] This embodiment 2 is basically the same as embodiment 1, the difference is:

[0075] In S2, the cracking temperature of sodium citrate is 800°C.

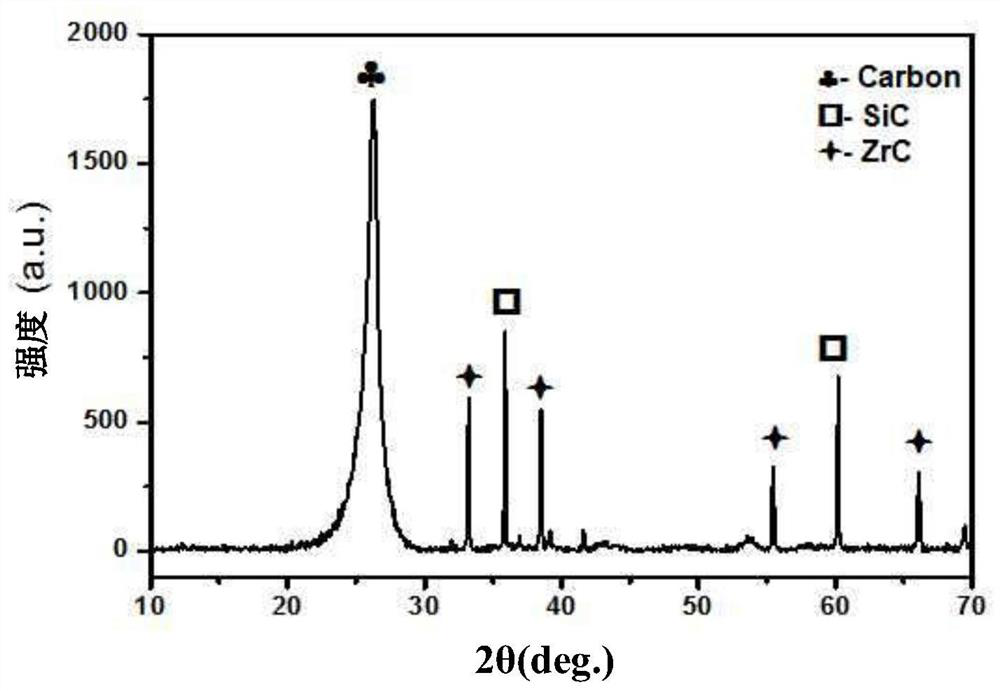

[0076] Results: A porous carbon / carbon composite material with higher crystallinity and higher reaction degree than in Example 1 was obtained. The XRD of the porous carbon / carbon composite is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com