Transparent gas sensor based on copper oxide/zinc oxide heterostructure, and preparation method thereof

A gas sensor and heterostructure technology, applied in the direction of material resistance, etc., can solve the problems of gas sensor sensitivity and detection limit being difficult to meet actual use requirements, and achieve the effect of improving efficiency and sensitivity, increasing porosity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

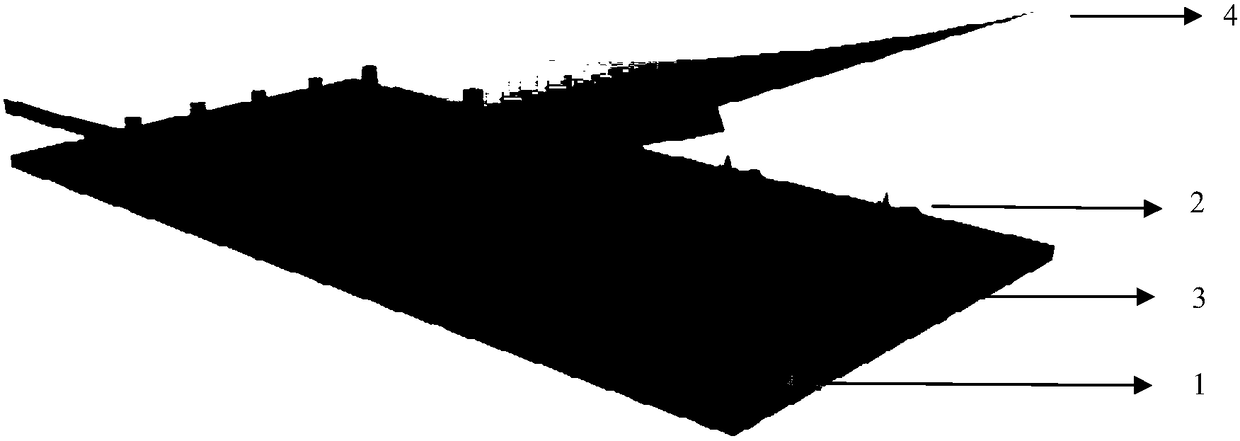

[0021] A transparent gas sensor based on a copper oxide / zinc oxide heterostructure, the sensor includes an ITO glass substrate 1, a copper oxide / zinc oxide heterostructure layer and a top electrode layer 4 deposited on the substrate, the oxide The copper / zinc oxide heterostructure layer includes branched copper oxide 2 and zinc oxide nanostructure layer 3 .

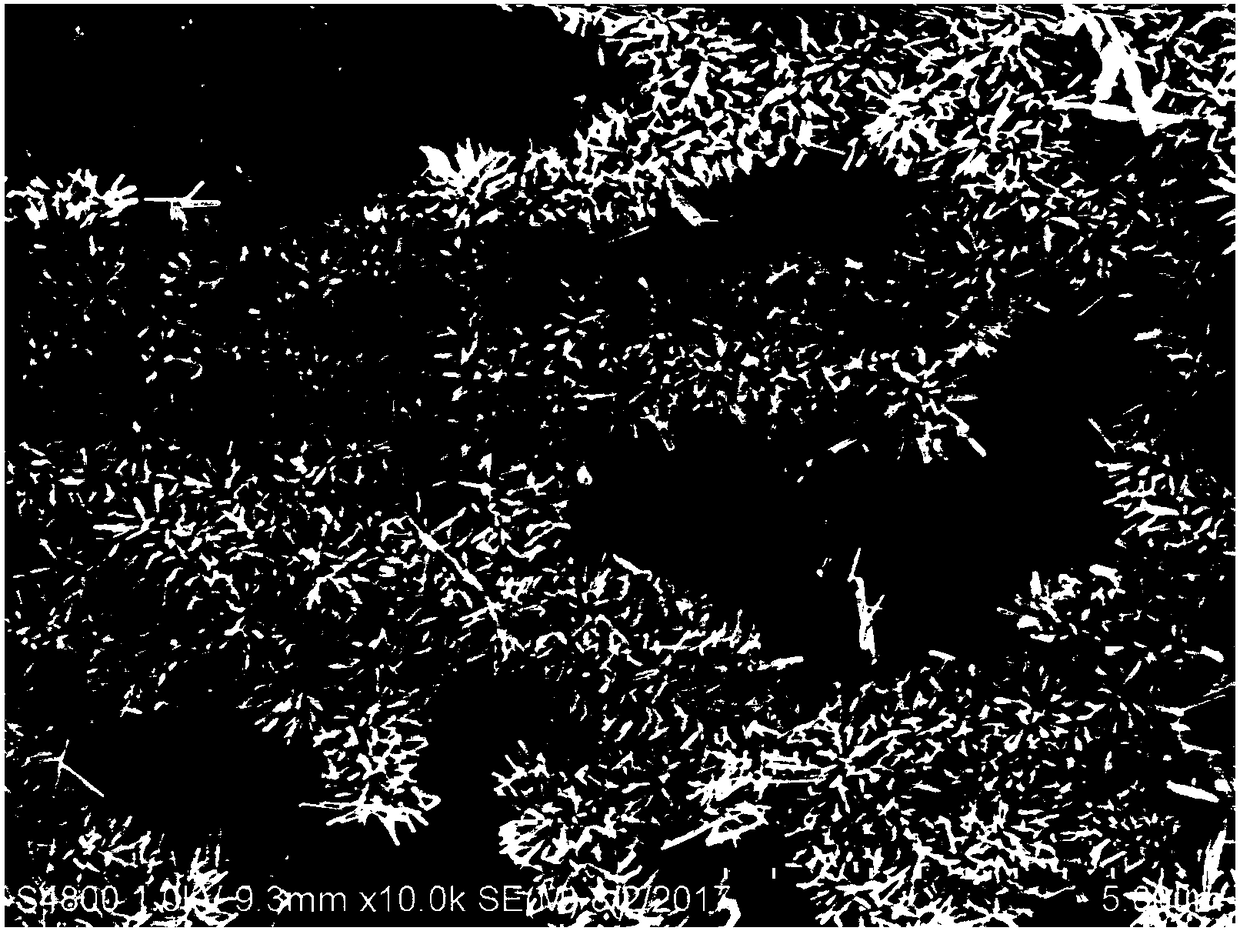

[0022] (1) Weigh 0.5 g of copper nanowires and disperse them into 800 mL of deionized water, and heat them in a water bath at 60° C.; the diameter of the copper nanowires is about 100 nm, and the length is about 20 μm;

[0023] (2) Take 3L of oxygen with a balloon, and continuously feed oxygen into the copper nanowire system by connecting the syringe;

[0024] (3) After oxidizing for 1 hour, the product was suction-filtered and vacuum-dried to finally obtain a copper oxide nanowire branch structure, which was sprayed onto a glass sheet for use;

[0025] (4) Weigh zinc acetate dihydrate, methyl alcohol, polyvinyl alcohol ...

Embodiment 2

[0030] A transparent gas sensor based on a copper oxide / zinc oxide heterostructure, the sensor includes an ITO glass substrate 1, a copper oxide / zinc oxide heterostructure layer and a top electrode layer 4 deposited on the substrate, the oxide The copper / zinc oxide heterostructure layer includes branched copper oxide 2 and zinc oxide nanostructure layer 3 .

[0031] (1) Weigh 0.5g of copper nanowires and disperse them in 800mL of ethanol, and heat in a water bath at 60°C; the diameter of the copper nanowires is about 100nm, and the length is about 20μm;

[0032] (2) Take 3L of oxygen with a balloon, and continuously feed oxygen into the copper nanowire system by connecting the syringe;

[0033] (3) After oxidizing for 1 hour, the product was suction-filtered and vacuum-dried to finally obtain a copper oxide nanowire branch structure, which was sprayed onto a glass sheet for use;

[0034] (4) Weigh zinc acetate dihydrate, methyl alcohol, polyvinyl alcohol and dissolve in ethan...

Embodiment 3

[0039] A transparent gas sensor based on a copper oxide / zinc oxide heterostructure, the sensor includes an ITO glass substrate 1, a copper oxide / zinc oxide heterostructure layer and a top electrode layer 4 deposited on the substrate, the oxide The copper / zinc oxide heterostructure layer includes branched copper oxide 2 and zinc oxide nanostructure layer 3 .

[0040] (1) Weigh 0.5 g of copper nanowires and disperse them into an equal-volume mixed system of 800 mL of ethanol and water, and heat in a water bath at 60 ° C; the diameter of the copper nanowires is about 100 nm, and the length is about 20 μm;

[0041] (2) Take 3L of oxygen with a balloon, and continuously feed oxygen into the copper nanowire system by connecting the syringe;

[0042] (3) After oxidizing for 1 hour, the product was suction-filtered and vacuum-dried to finally obtain a copper oxide nanowire branch structure, which was sprayed onto a glass sheet for use;

[0043] (4) Weigh zinc acetate dihydrate, methy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com