Tumor targeted therapy sustained release preparation and preparation method thereof

A technology of tumor-targeting and sustained-release preparations, which is applied in the nanometer field, can solve the problems of unfavorable biological applications, lack of performance, etc., and achieve excellent hydrophilicity and dispersibility, and excellent drug loading efficiency, the effect of enriching surface groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1 Ti 3 AlC 2 Synthesis of MXenes

[0062] Titanium powder (99.5% (w / w) purity, -325 mesh), aluminum powder (99.5% (w / w) purity, -325 mesh) and graphite powder (99.0% (w / w) purity, particle size smaller than 48μm, -300 mesh) was mixed at a molar ratio of 2:1:1, and then ball milled for 10 hours, then pressed into a round cake under a pressure of 30MPa, and then the round cake was placed in a furnace under the condition of argon gas Next, fired at 1500℃ for 2 hours to obtain Ti 3 AlC 2 Ceramic material.

[0063] Will get Ti 3 AlC 2 After the ceramic material is ground, 10g of powder is collected and placed in 60ml of a 40% concentration of hydrofluoric acid aqueous solution. The etching reaction is carried out at room temperature for 3 days, then collected by centrifugation and washed with water and ethanol, and then dispersed in 50ml Stir in a 25% (w / w) TPAOH (Tetrapropylammonium hydroxide) aqueous solution at room temperature for 3 days; then centrifuge and wash wit...

Embodiment 2

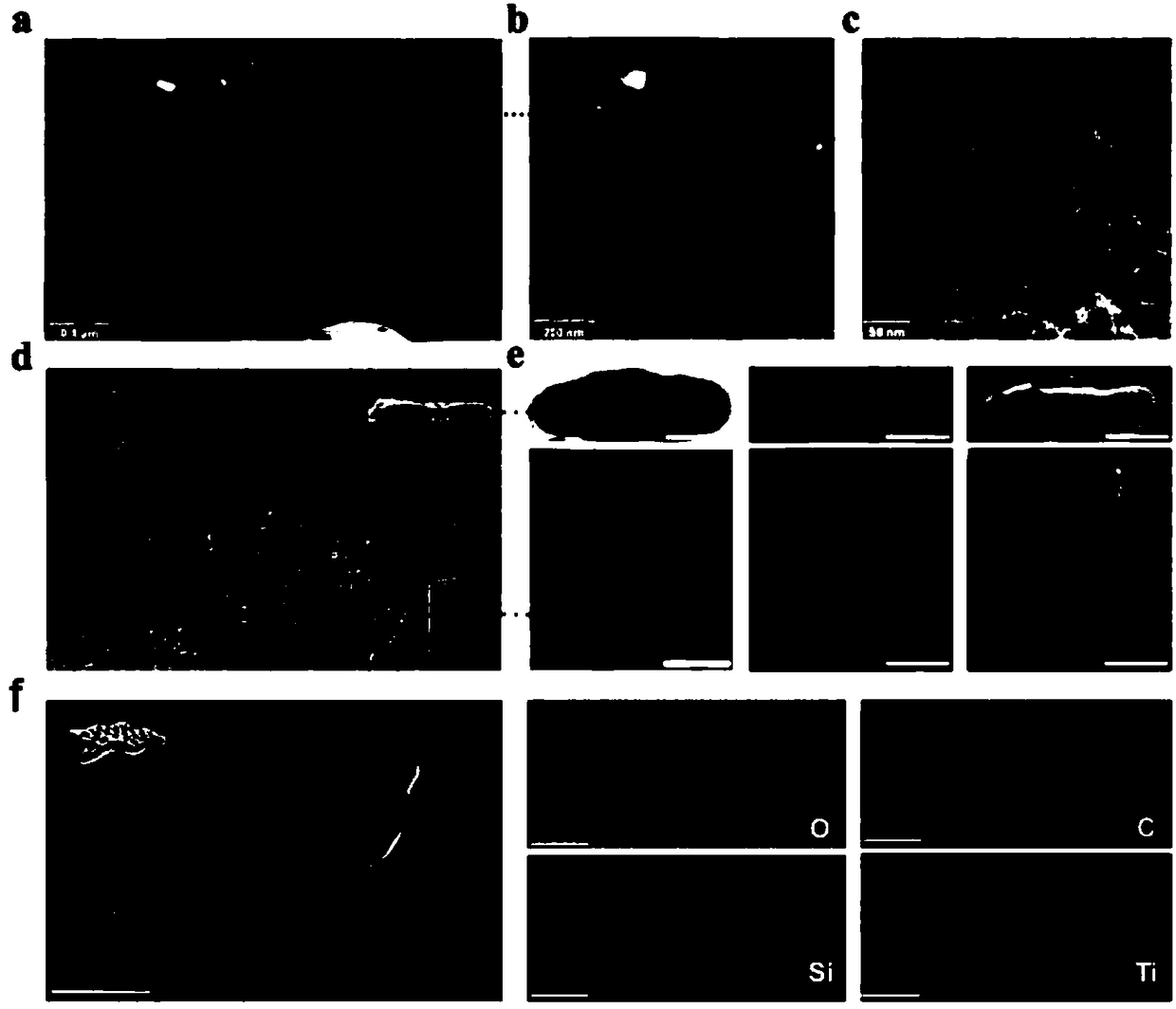

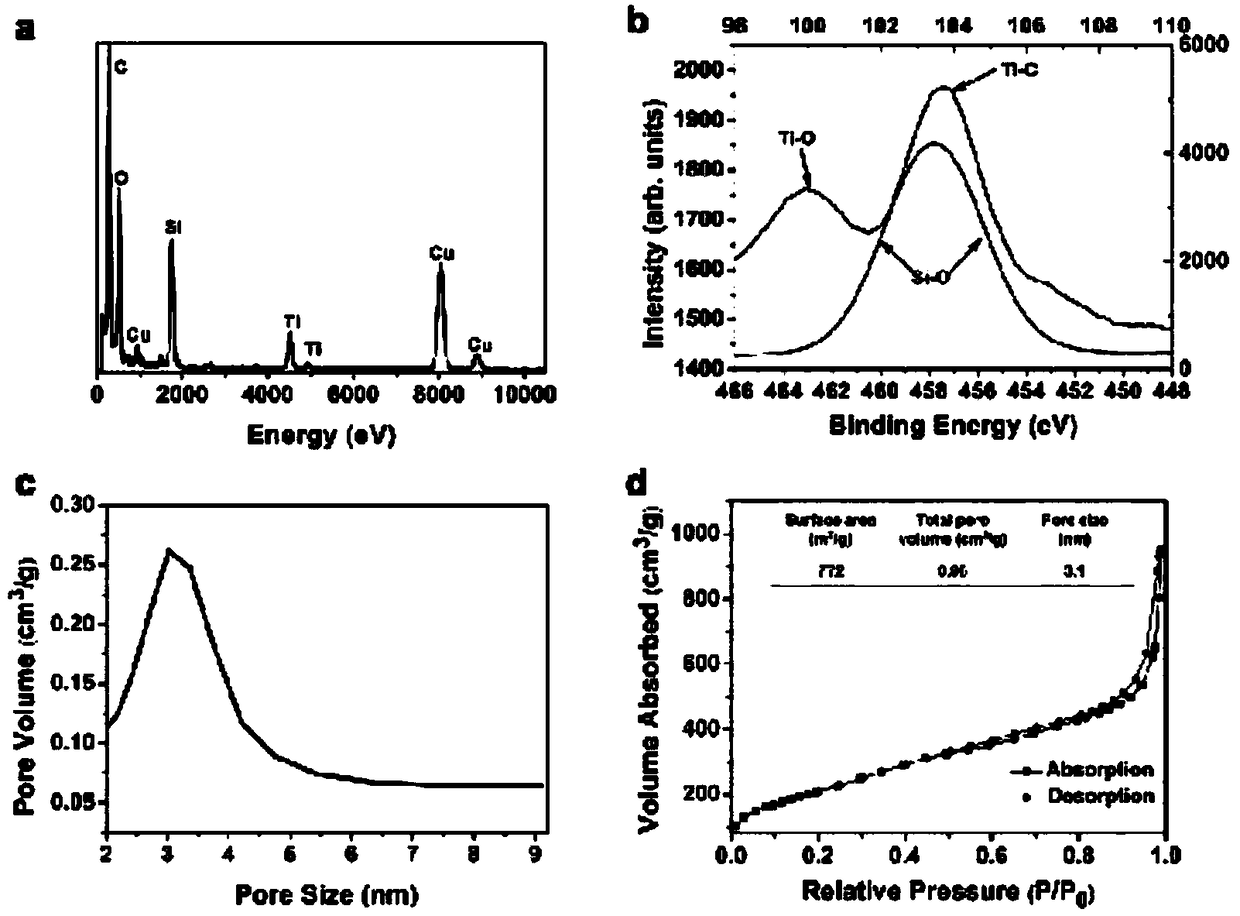

[0065] Example 2 Synthesis of MXene nanosheets coated with mesoporous silica

[0066] Premix 10g of 10% (w / w) CTAC (Cetanecyltrimethylammonium chloride) aqueous solution and 0.2g of 10% (w / w) TEA (triethanolamine) aqueous solution at room temperature for 10 minutes, then add 10ml of concentration dropwise Ti obtained in Example 1 at 0.5 mg / ml 3 AlC 2 The aqueous solution of MXenes was stirred at room temperature for 1.5 hours; after that, 150 μl of TEOS was added and stirred at 80°C for 1 hour; then the precipitate was collected by centrifugation and washed with ethanol 3 times. In the above reaction process, CTAC acts as a mesoporous structure guide agent, which can be achieved by using a mixed solvent of ethanol and 37% hydrochloric acid (V Ethanol :V 37% hydrochloric acid =10:1) Wash out at 78°C for 3 times for 12 hours. After that, after washing with ethanol 3 times and washing with deionized water 2 times, the resultant was dispersed in ethanol. Take in-situ bright-field...

Embodiment 3

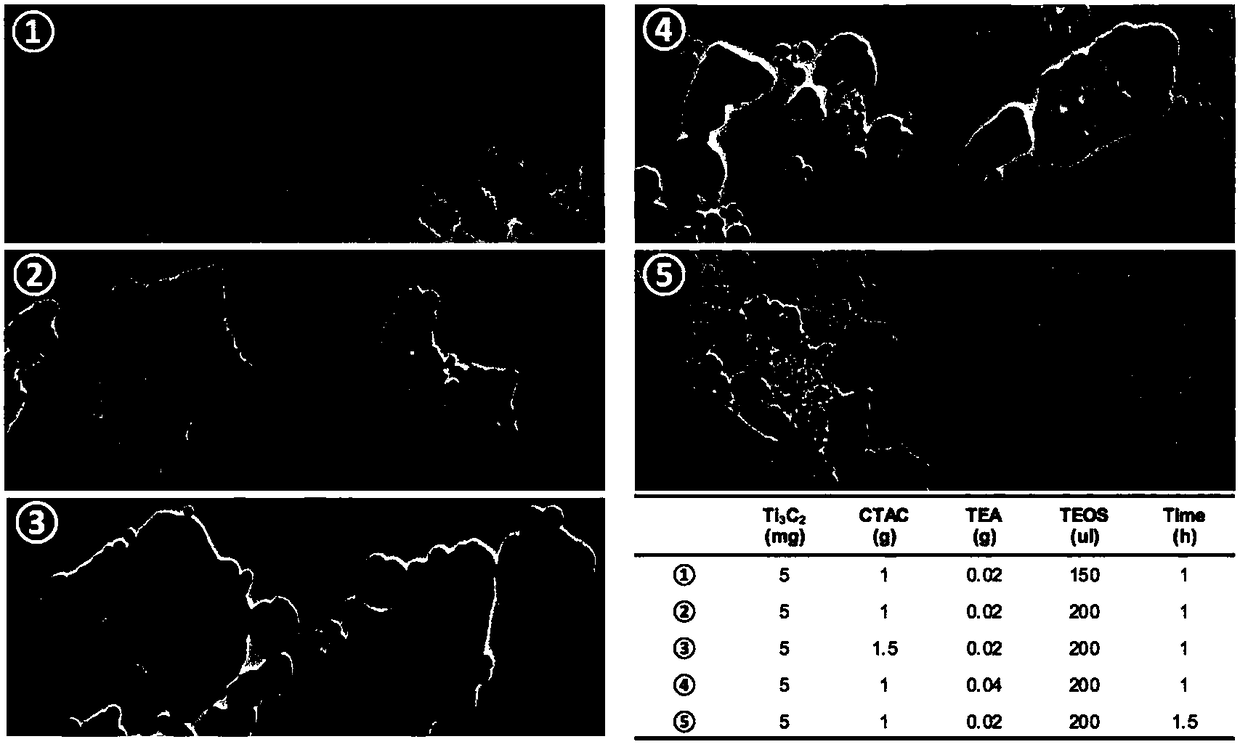

[0070] On the basis of the scheme of embodiment 2, this embodiment also examines different Ti 3 C 2 The weight ratio of MXenes, CTAC and TEA and TEOS and Ti 3 C 2 The effect of the volume ratio of MXenes material aqueous solution on the microstructure of the obtained material, the results are as follows image 3 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com