Double-light beam micro/nano optical manufacturing method

An optical manufacturing and double-beam technology, which is applied in the fields of optics, nanotechnology, and optomechanical equipment, can solve the problems of small center distance, low pattern and structure feature density, and ultraviolet light energy loss, etc., to achieve strong mechanical strength, The effect of high feature sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present invention can be applicable to single-focus laser direct writing, such as Figure 4 As shown, the manufacturing light forms the optical path of the manufacturing light, and the auxiliary light forms the optical path of the auxiliary light. A beam expander E1 and a beam expander E2 are respectively placed in front of the manufacturing light and the auxiliary light, and the spatial phase modulators P1 and P2 are respectively placed after the beam expander. E1 and P1 are coaxially placed, and E2 and P2 are coaxially placed. The beam expansion and phase modulation of the manufacturing light and auxiliary light are combined by the dichroic mirror D. After the beam is combined, they are focused on the processing material to be irradiated through the objective lens at the same time. .

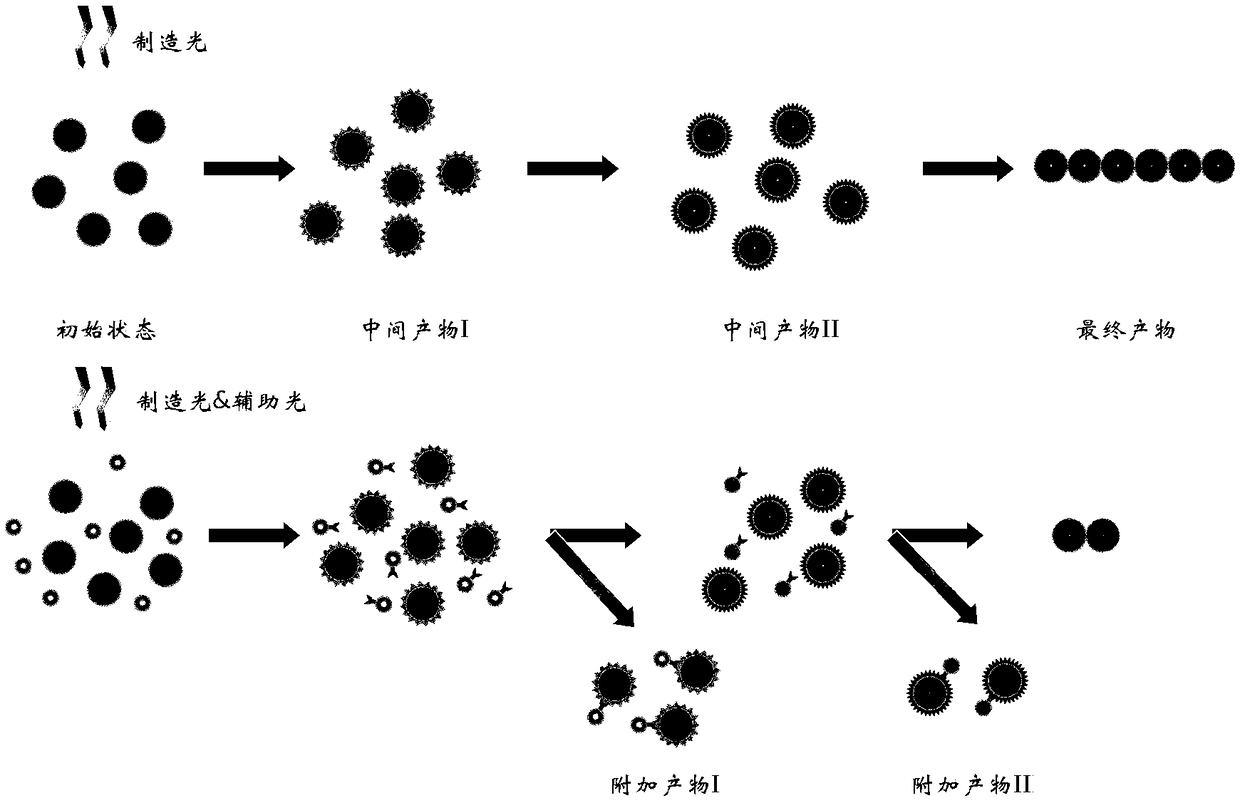

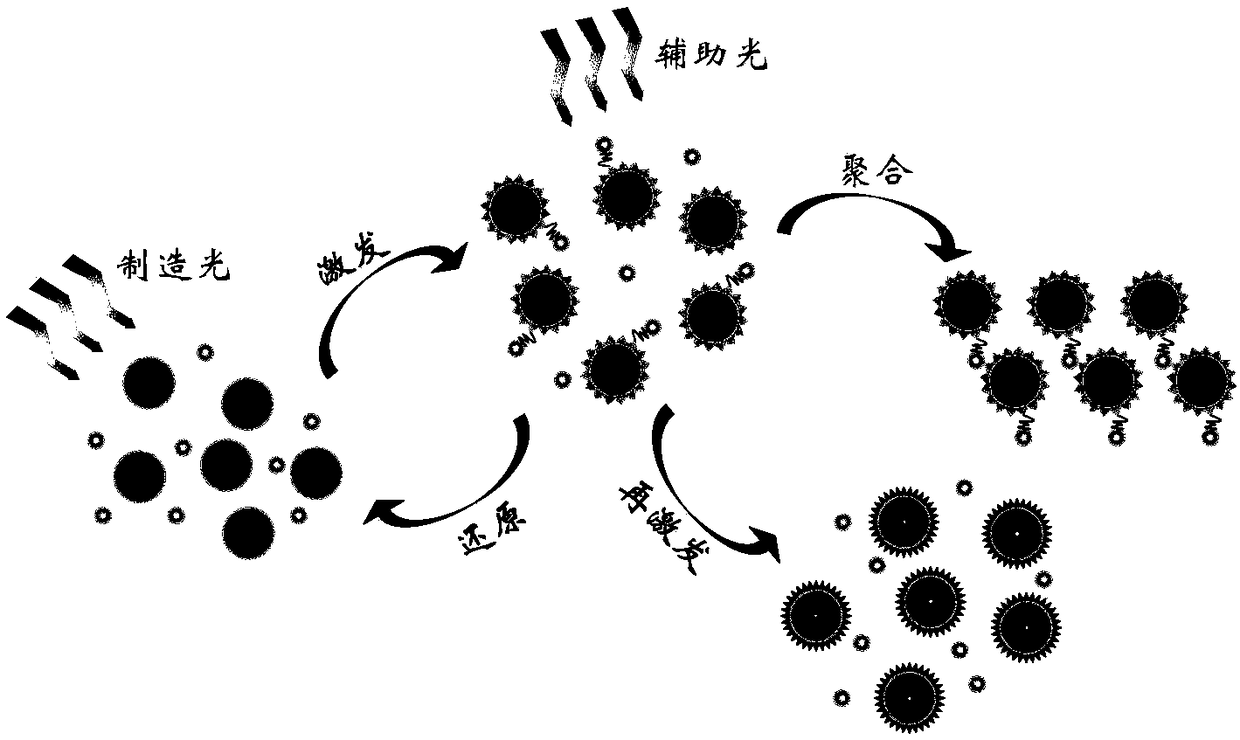

[0057] Single-focal feature size reduction can be achieved through the combined action of fabrication light and auxiliary light. Such as Figure 5 As shown in , the manufacturing...

Embodiment 2

[0061] The commonly used single-focus laser direct writing technology focuses a beam of light into the direct writing material and generally forms only a single focused spot. According to the method of the present invention applied to the multi-focus laser direct writing technology, by adjusting the light intensity, phase and polarization of the manufacturing light, a beam of light can be focused into the direct writing material to form multiple focused light spots. Generally, it can be realized by using a spatial light modulator to adjust the phase of light.

[0062] Multi-focus laser direct writing with Figure 4 The shown single-focus laser direct writing devices are the same, and it should be pointed out that the single-focus laser direct writing and multi-focus laser direct writing use different spatial phase modulators. Such as Figure 11 As shown, the manufactured light can also form multi-focus spots with Gaussian distribution after beam expansion and spatial phase m...

Embodiment 3

[0067] The invention can be applied to holographic grating manufacture. The holographic grating uses the principle of coherent superposition of light to image the interference fringes on the photosensitive material, and then dissolves the photosensitive (or non-photosensitive) part by developing technology to obtain a holographic grating. Such as Figure 16 As shown, in the manufacture of holographic gratings, two beams of light are formed by the manufacturing light and the auxiliary light respectively, and interference fringes are formed at the same position. The manufacturing light is divided into two beams with the same power by the beam splitter B1, and then passed by the beam expander E1 1 and E1 2 After the beam expands, they reach the mirror M1 respectively 1 and M1 2 , via M1 1 and M1 2 After reflection, it is focused on the photosensitive screen to form interference fringes; similarly, the auxiliary light is divided into two beams of equal power by the beam spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com