Composite lithium metal anode

A metal negative electrode and composite lithium technology, which is applied in battery electrodes, lithium batteries, electrical components, etc., can solve the problems of complex synthesis conditions, limited development, and high price, so as to improve Coulombic efficiency, prevent ion concentration gradients, and improve lifespan Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

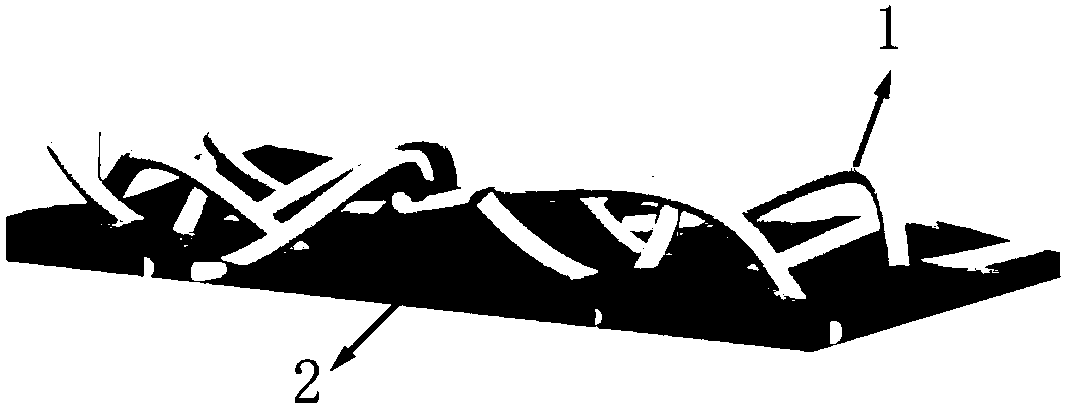

[0037] A 200 μm thick quaternary ammonium salt modified polybutylene terephthalate fiber skeleton is placed on the current collector copper foil, and the lithium sheet is used as the negative electrode to assemble a half-cell, and the electrolyte is 1M bistrifluoromethanesulfonyl Lithium amide (LiTFSI) in 1,3-dioxolane (DOL) / ethylene glycol dimethyl ether (DME) (1:1, volume ratio) solution. Cell assembly was performed in an argon-protected glove box using a 2032-size coin cell.

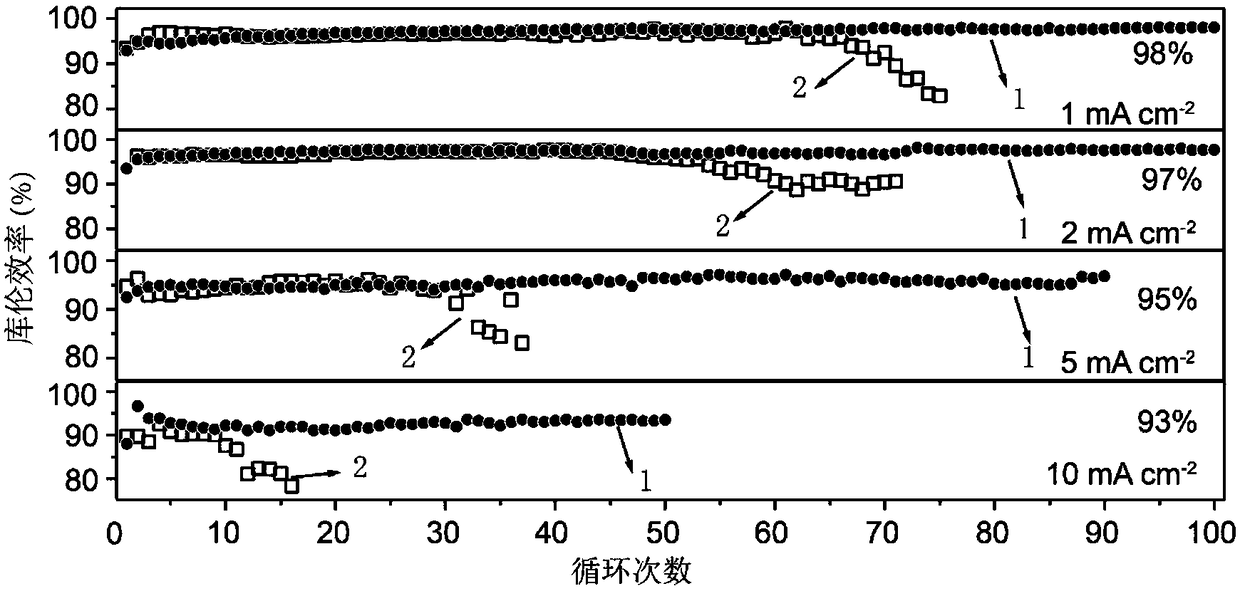

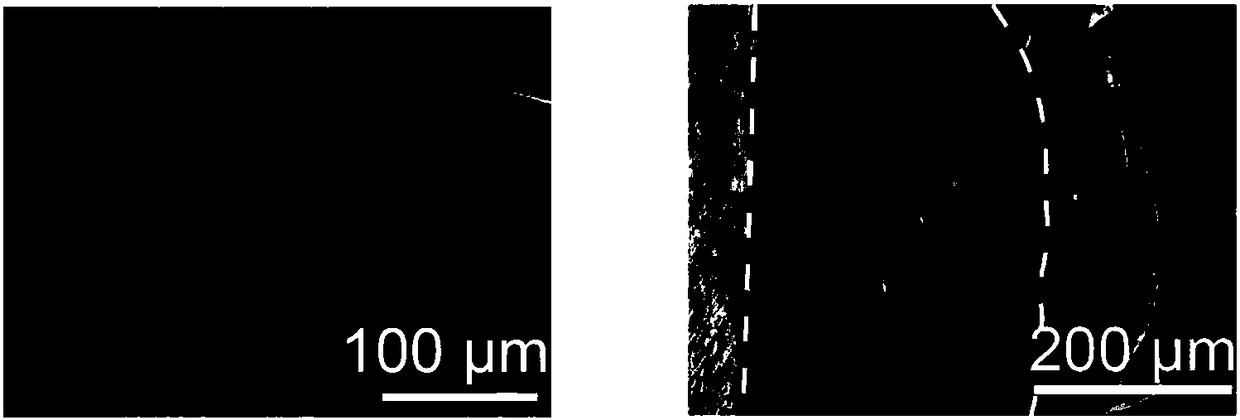

[0038] The test conditions of the assembled half-cells are as follows: the surface capacity of the electrodeposition / stripping lithium metal active material is 1mAhcm -2 , to form a composite electrode with a three-dimensional framework, at a current density of 1mA cm -2 , 2mA cm -2 , 5mA cm -2 , 10mA cm -2 Under the conditions, the cycle number-coulombic efficiency curve can be found in figure 2 , it can be seen from the figure that the corresponding Coulombic efficiencies can be maintained at ...

Embodiment 2

[0041] A 200 μm-thick quaternary ammonium salt-modified polybutylene terephthalate fiber skeleton was placed on a 450-μm-thick lithium metal sheet, and a composite metal lithium negative electrode was formed in situ after charge-discharge deposition and stripping to assemble a symmetrical battery. The electrolyte is 1M lithium bistrifluoromethanesulfonimide (LiTFSI) in 1,3-dioxolane (DOL) / ethylene glycol dimethyl ether (DME) (1:1, volume ratio) solution.

[0042] The test conditions of the assembled symmetrical battery are: electrodeposited / stripped lithium metal active material surface capacity is 1mAh cm -2 , with a three-dimensional framework to form a composite electrode, at a current density of 3mA cm -2 , 5mA cm -2 , 10mA cm -2 Under the condition, its time-voltage curve is shown in Figure 4 , it can be seen from the figure that the cycle stability and life of the symmetrical battery assembled with the composite lithium metal anode have been greatly improved.

Embodiment 3

[0044] The quaternary ammonium salt-modified polybutylene terephthalate fiber skeleton with a thickness of 200 μm is placed on a lithium metal sheet with a thickness of 450 μm, and a composite metal lithium negative electrode is formed in situ after charge-discharge deposition and stripping, and lithium iron phosphate (LiFePO 4 ) to assemble a half-cell, the electrolyte is 1M lithium hexafluorophosphate (LiPF 6 ) in ethylene carbonate (EC) and diethyl carbonate (DEC) (1:1, volume ratio) solution.

[0045] The discharge specific capacity (curve 1) and Coulombic efficiency (curve 3) curves of the half-cell assembled with the composite lithium metal negative electrode and the lithium iron phosphate electrode are as follows: Figure 5 It can be seen from the figure that under the condition of 0.5C rate, after 150 cycles, the measured discharge capacity can still remain stable, while the discharge specific capacity (curve 2) and Coulombic efficiency of the half-cell assembled with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com