Method for recovering palladium from palladium-contained catalyst

A palladium catalyst and recovery method technology, applied in the direction of improving process efficiency, etc., can solve the problems of toxic and harmful gases, low leaching rate, large acid mist, etc., and achieve the effect of increasing leaching rate, high extraction rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

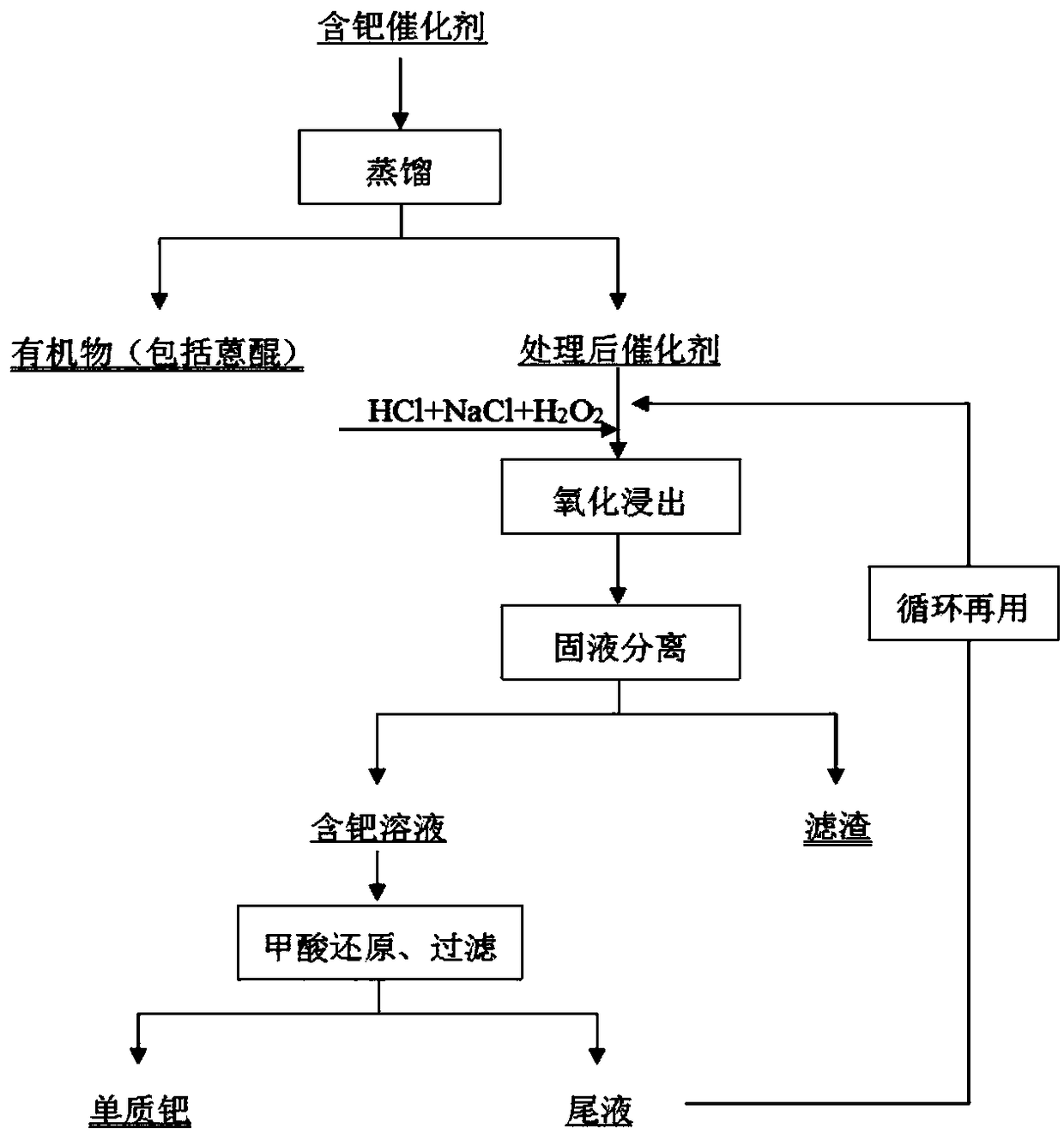

Image

Examples

Embodiment 1

[0027] The spent palladium-containing catalyst was distilled at 150°C for 10 h to remove organic matter such as anthraquinone. Prepare a palladium leaching solution. The concentration of each component in the leaching solution is: hydrochloric acid 8mol / L, hydrogen peroxide 100g / L, and the spent catalyst after removing organic matter is stirred and heated to 50°C in the leaching solution for oxidative complexation for 0.5h to obtain a palladium-containing solution (i.e. palladium-containing leachate). The palladium-containing solution was reduced with formic acid to obtain elemental palladium powder. During the process of obtaining elemental palladium by formic acid reduction, the volume ratio of formic acid to solution was controlled to be 20:1, the reduction temperature was 60°C, and the reaction was 2 hours. The recovery rate of palladium could reach 97.5%. After using sodium hydroxide to adjust the pH of the tail liquid to 7, it can be recycled.

Embodiment 2

[0029] The spent palladium-containing catalyst was distilled at 160°C for 9.5h to remove organic matter such as anthraquinone. Prepare a palladium leaching solution, the concentration of each component in the leaching solution is: hydrochloric acid 8mol / L, sodium chloride concentration 1mol / L, hydrogen peroxide 100g / L, and the spent catalyst after removal of organic matter is stirred and heated to 55°C in the leaching solution to oxidize and complex After 0.5h, a palladium-containing solution (ie palladium-containing leaching solution) was obtained. The palladium-containing solution was reduced with formic acid to obtain elemental palladium powder. In the process of obtaining elemental palladium by formic acid reduction, the volume ratio of formic acid to solution was controlled to be 20:1, the reduction temperature was 63°C, and the reaction was 2 hours. The recovery rate of palladium could reach 99.5%. After using sodium hydroxide to adjust the pH of the tail liquid to 7, it...

Embodiment 3

[0031] The spent palladium-containing catalyst was distilled at 170°C for 9h to remove organic matter such as anthraquinone. Prepare a palladium leaching solution, the concentration of each component in the leaching solution is: hydrochloric acid 7.5mol / L, sodium chloride concentration 1mol / L, hydrogen peroxide 95g / L, the waste catalyst after removing organic matter is stirred and heated to 55°C in the leaching solution to oxidize the complex combined for 0.8h to obtain a palladium-containing solution (that is, a palladium-containing leaching solution). The palladium-containing solution is reduced with formic acid to obtain elemental palladium powder. During the process of obtaining elemental palladium by formic acid reduction, the volume ratio of formic acid to solution is controlled to be 18:1, the reduction temperature is 65°C, and the reaction is 1.8 hours. The recovery rate of palladium can reach 98.6%. . After using sodium hydroxide to adjust the pH of the tail liquid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com