Bell type platinum-based magnetic space confinement catalyst and preparation method thereof

A catalyst and platinum-based technology, applied in the field of catalyst and its preparation, can solve the problems of reducing structural stability, increasing the agglomeration and loss of noble metal nanoparticles, and limiting large-scale industrial applications, so as to avoid collision, avoid agglomeration or loss, The effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

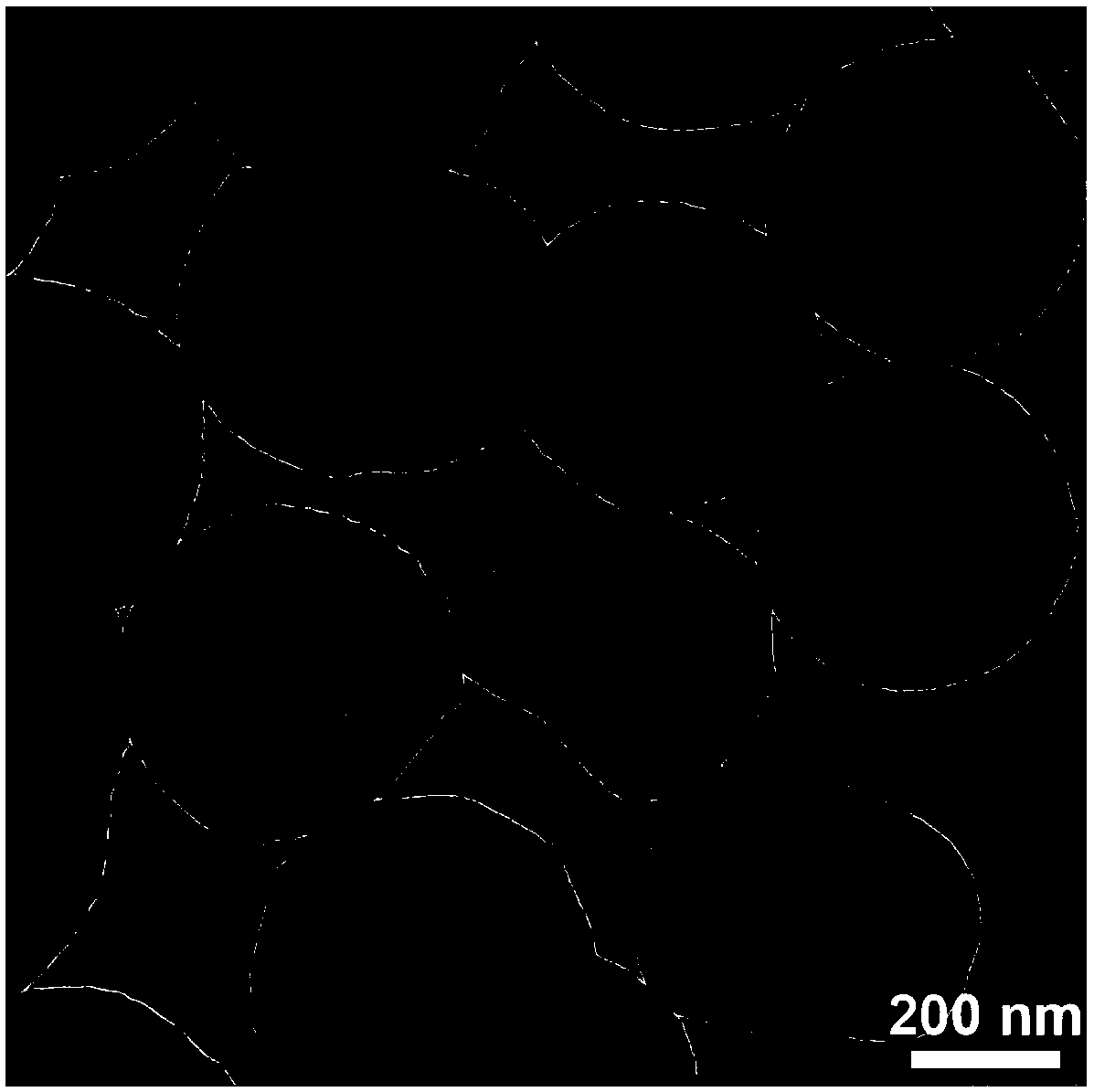

Embodiment 1

[0021] In 40mL ethylene glycol, add 1.08g FeCl successively 3 ·6H 2 O. 0.108g of polyacrylic acid and 9g of anhydrous sodium acetate, after completely dissolving to form a homogeneous mixture, add to a 50mL reactor, react at 200°C for 14 hours, wash the product alternately with absolute ethanol and distilled water three times, and dry the product at 60°C After 12 hours, a polyacrylic acid-modified Fe with a particle size of 250 nm was obtained 3 o 4 Nanoparticles;

[0022] The above polyacrylic acid modified Fe 3 o 4 The nanoparticles were dispersed in a mixed solvent of ethanol and water at a ratio of 4:1 to form polyacrylic acid-modified Fe at a concentration of 1 g / L 3 o 4 Nanoparticle dispersion, then according to the mixed solvent and ammonia water volume ratio of 15:1, add ammonia water with a mass concentration of 28wt%, after mechanical stirring at 30°C for 10 minutes, according to the volume ratio of ammonia water to tetraethyl orthosilicate of 10:1 Tetraethyl ...

Embodiment 2

[0027] In 40mL ethylene glycol, add 1.08g FeCl successively 3 ·6H 2 O. 0.108g of polyacrylic acid and 9g of anhydrous sodium acetate, after completely dissolving to form a homogeneous mixture, add to a 50mL reactor, react at 200°C for 14 hours, wash the product alternately with absolute ethanol and distilled water three times, and dry the product at 60°C After 12 hours, a polyacrylic acid-modified Fe with a particle size of 250 nm was obtained 3 o 4 Nanoparticles;

[0028] The above polyacrylic acid modified Fe 3 o 4 The nanoparticles were dispersed in a mixed solvent of ethanol and water at a ratio of 4:1 to form polyacrylic acid-modified Fe at a concentration of 1 g / L 3 o 4 Nanoparticle dispersion, then according to the mixed solvent and ammonia water volume ratio of 20:1, add ammonia water with a mass concentration of 28wt%, after mechanical stirring at 30°C for 10 minutes, according to the volume ratio of ammonia water to tetraethyl orthosilicate is 10:1 Add tetraet...

Embodiment 3

[0034] In 40mL ethylene glycol, add 1.08g FeCl successively 3 ·6H 2O. 0.108g of polyacrylic acid and 9g of anhydrous sodium acetate, after completely dissolving to form a homogeneous mixture, add to a 50mL reactor, react at 200°C for 14 hours, wash the product alternately with absolute ethanol and distilled water three times, and dry the product at 60°C After 12 hours, a polyacrylic acid-modified Fe with a particle size of 250 nm was obtained 3 o 4 Nanoparticles;

[0035] The above polyacrylic acid modified Fe 3 o 4 The nanoparticles were dispersed in a mixed solvent of ethanol and water at a ratio of 4:1 to form polyacrylic acid-modified Fe at a concentration of 1 g / L 3 o 4 Nanoparticle dispersion, then add ammonia water with a mass concentration of 28wt% according to the volume ratio of the mixed solvent to ammonia water at 25:1, and mechanically stir at 30°C for 10 minutes, then add ammonia water to tetraethyl orthosilicate at a volume ratio of 10:1 Tetraethyl orthos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com